Automatic loom high-intelligence broken end processing system

A technology for processing systems and looms, applied in looms, textiles, textiles and papermaking, etc., can solve problems that affect the degree of equipment automation, reduce labor productivity, and hinder product quality, so as to improve labor productivity, reduce labor utilization rate, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The new technological process of the automatic loom high-intelligence broken end processing system of this scheme is as follows:

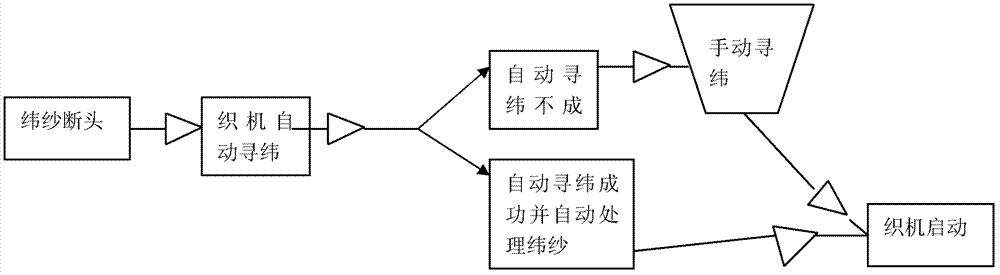

[0011] as attached figure 1 , From the analysis of the weft yarn breakage operation process, as long as the form of weft yarn breakage is effectively controlled to improve the success rate of automatic weft finding, the effect of automatic weft yarn processing on the loom can be improved, thereby achieving the effect of improving labor productivity.

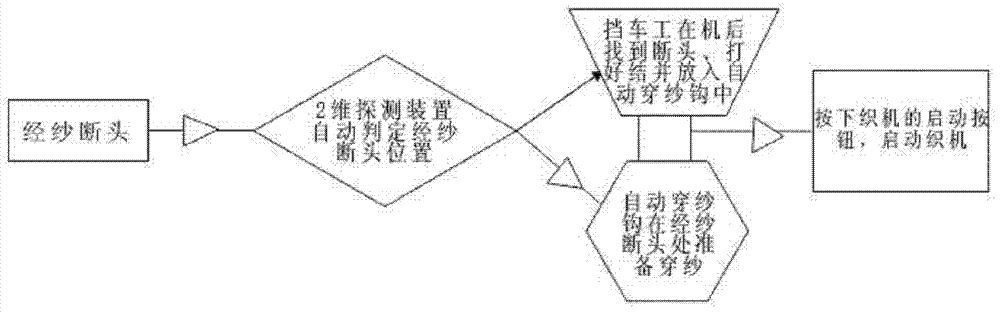

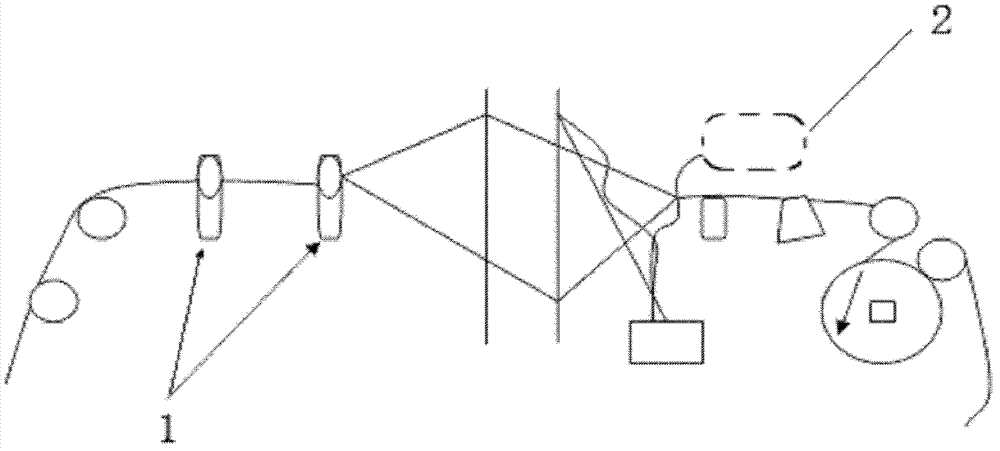

[0012] as attached figure 2 And attached image 3 , the loom cancels the original warp breakage detection device 1, and installs a fully automatic 2D vision system 2 at the weaving opening of the loom. This 2D vision system can detect the entire production process and can quickly detect warp breakage. The broken end position of the warp yarn and stop immediately; on the 2-dimensional vision system 2 device, an automatic yarn threading device is installed at the same time.

[0013] The trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com