Bridge viscous damping shock-absorption supporting seat

A technology of viscous damping and shock-absorbing bearings, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems that the sliding plate is easy to be crushed and scratched, and affects the design parameters of the bearings and the entire structure, and achieves a simple structure , prolong life, reduce the effect of acceleration and displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

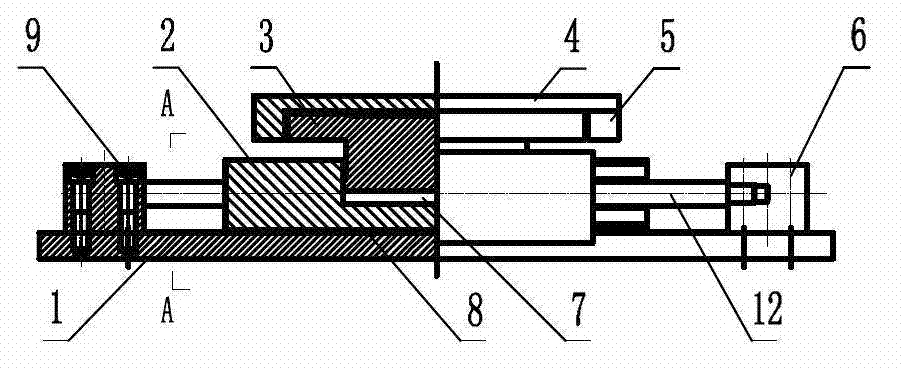

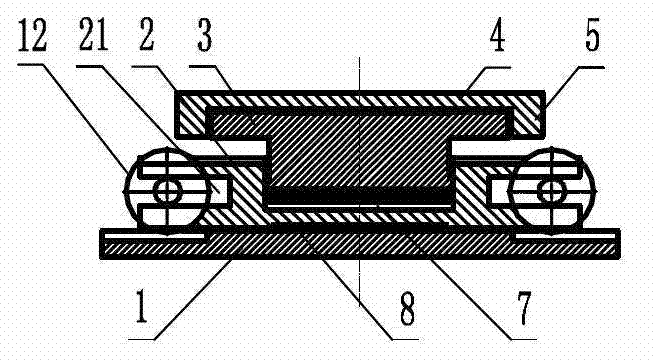

[0025] See Figure 1 ~ Figure 3 , A bridge viscous damping damping support, comprising a support bottom plate 1, a middle basin plate 2, a steel liner 3, a support top plate 4, and a viscous damper 12, the viscous damper 12 along the bridge It is installed longitudinally on the left and right sides of the middle basin plate 2. The piston shafts at both ends of the viscous damper are connected by bolts to the connecting block 6 fixed on the base plate of the support. The left and right sides of the middle basin plate 2 are respectively provided with two Two side clips 21, the two side bayonet on the left side clamp both ends of the working cylinder of the left viscous damper, and the two side bayonet on the right side clamp both ends of the working cylinder of the right viscous damper, supporting The seat bottom plate is provided with a shear plate 10 along the longitudinal front and rear ends of the bridge. The shear plate is fixed on the support bottom plate by a shear pin 11, ...

Embodiment 2

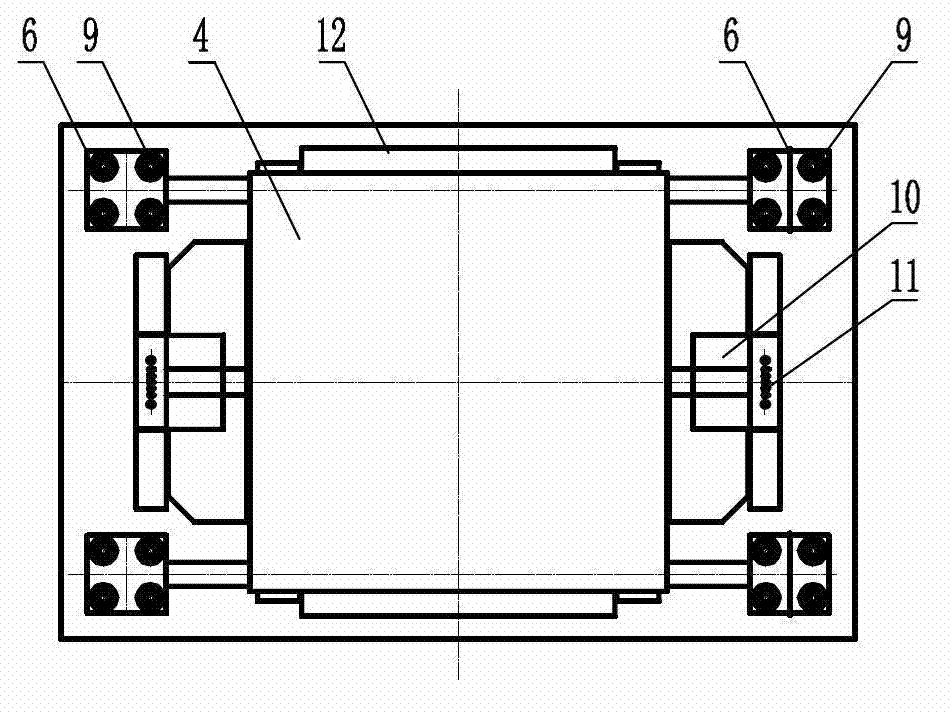

[0032] See Figure 4 ~ Figure 6 , A bridge viscous damping damping support, the viscous dampers 12 are installed on the left, right, front, and rear sides of the middle basin plate 2 along the longitudinal and transverse directions of the bridge, respectively There are side bayonet openings 21 respectively. The two side bayonet openings on the left and right sides of the middle basin plate 2 respectively clamp the two ends of the left and right viscous damper cylinders. The two front and rear sides of the middle basin plate 2 Each side bayonet respectively clamps the two end faces of the front and rear viscous damper working cylinders. Shear plates 10 are provided on the left, right, front and rear ends of the support base plate, and the shear plates are fixed on the support base plate by shear pins 11 .

[0033] The other structure is basically the same as the first embodiment.

[0034] In the installation method of the present invention, in general, the support base plate 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com