Self-balancing water-sealed fire-retarding and explosion-venting device for gas pipeline transportation

A technology for pipeline transportation and water sealing and fire resistance, which is applied in gas discharge, safety devices, mining equipment, etc., to achieve reasonable structural settings, solve the problem of water cover uncertainty, and achieve good water sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

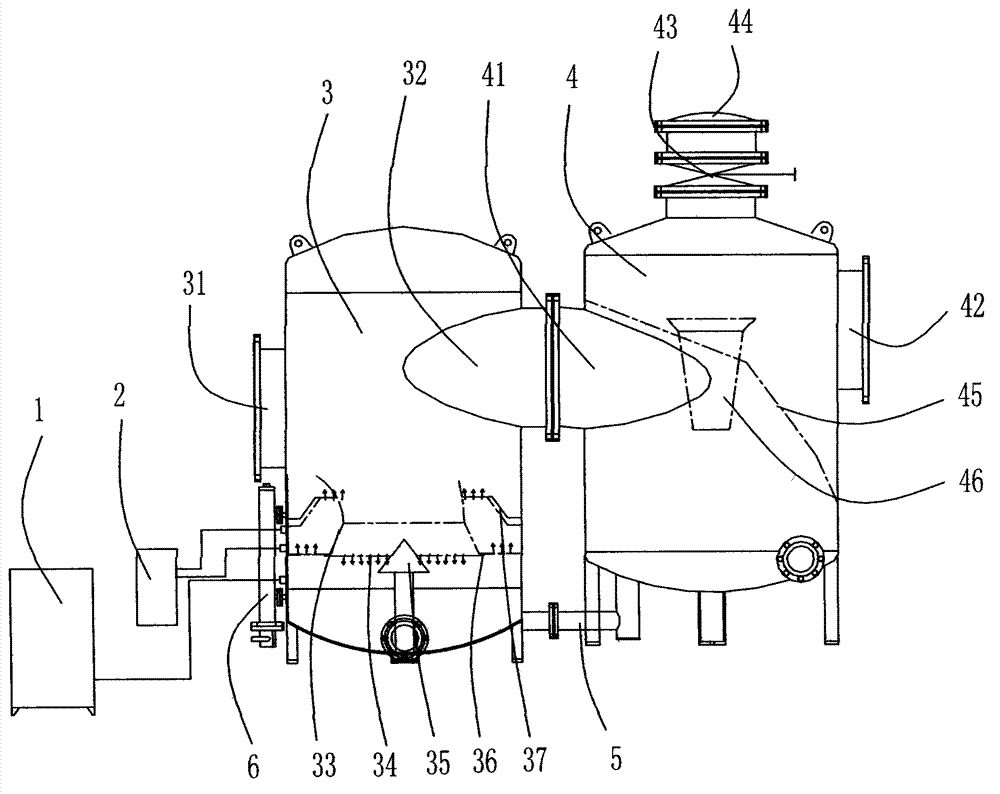

[0025] Such as figure 1 As shown, the self-balancing water seal fire arresting and explosion venting device for gas pipeline transportation according to the present invention includes a water seal cylinder 3, a water-gas separation cylinder 4 and an automatic water level control device.

[0026] The water sealer cylinder 3 and the water-gas separation cylinder 4 are connected to each other, specifically, the two sides of the water sealer cylinder 3 are respectively provided with an air inlet 31 and an exhaust outlet 32, so Two air inlets 41 and two air outlets 42 are respectively provided on both sides of the water-gas separation cylinder 4 , and the air outlet one 32 is fixedly connected to the air inlet two 41 . The gas enters the water-sealer cylinder 3 through the air inlet 1 31, and after being water-sealed, it enters the water-gas separation cylinder 4 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com