Box body of railway vehicle traveling gearbox

A technology for rail vehicles and gearboxes, which is applied to belts/chains/gears, transmission boxes, components with teeth, etc., and can solve problems such as unbalanced internal and external pressure differences, leakage, and limited operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

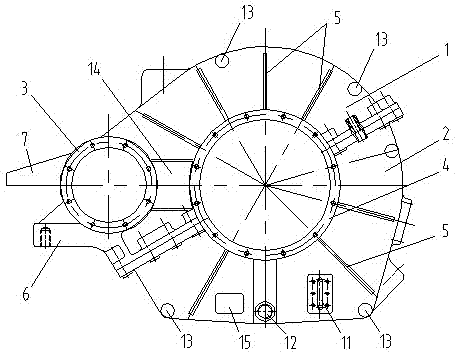

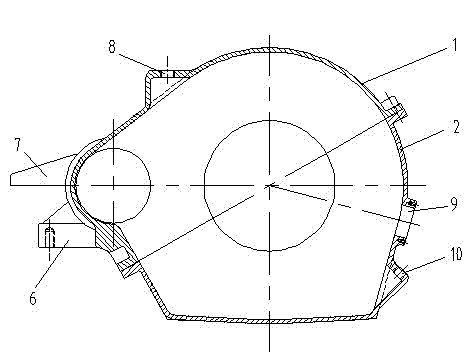

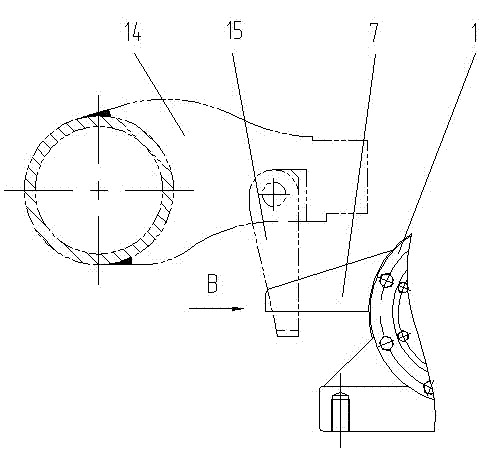

[0019] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

[0020] Such as figure 1 , 2 As shown, a rail vehicle running gear box body includes an upper box body 1 and a lower box body 2, the upper box body 1 and the lower box body 2 are fixedly connected to form a box body, and the box body has an input shaft bearing seat 3 and an axle shaft The bearing seat 4, the axle bearing seat 4 is a split structure, half of which is located on the upper box body 1, and the other half is located on the lower box body 2, and the joint surface between the upper box body 1 and the lower box body 2 is Arranged obliquely, the upper box body 1 and the lower box body 2 are distributed with several reinforcing ribs 5 on the surface, and the reinforcing ribs 5 extend outward from the periphery of the axle bearing seat 4, and the input shaft bearing seat 3 is located on the upper box body 1 as a whole , the end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com