Improved structure of burner for gas water heater

A gas-fired water heater and a technology with improved structure, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of high temperature life attenuation and damage of electronic components, affecting the service life of water heaters, burner burning, etc., to reduce internal temperature rise, The effect of slowing down aging and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

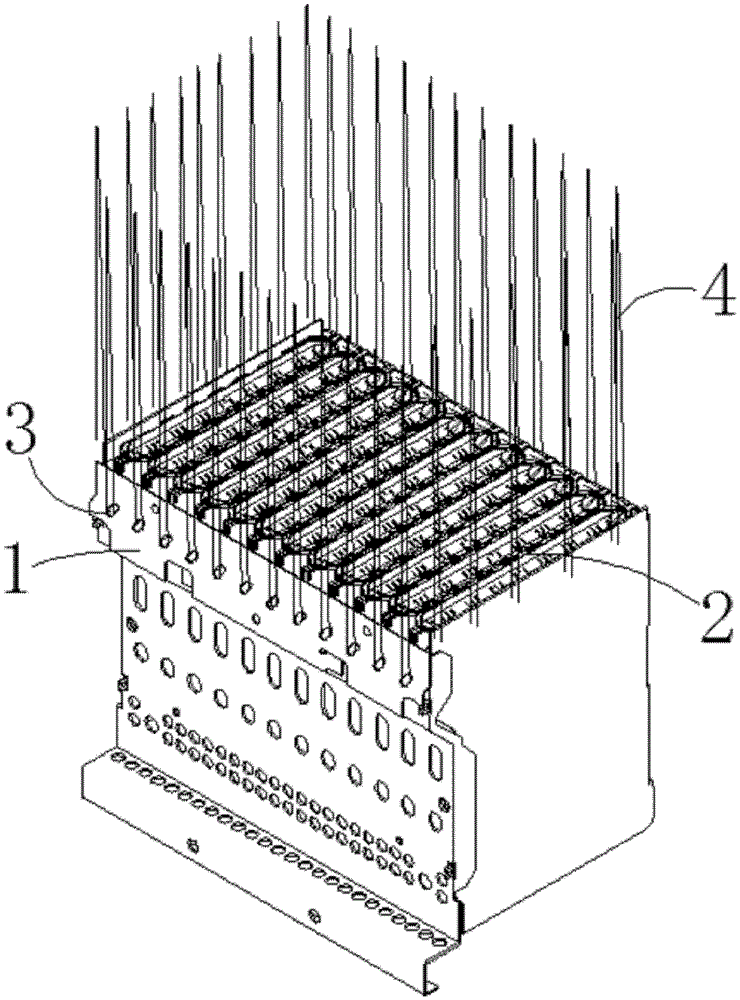

[0014] Embodiment: an improved structure of a burner for a gas water heater, the combustion

[0015] The upper end of the burner is provided with a fire rack 1, on which a number of fire racks 2 are fixed, a number of thick and thin burners and a number of common burners are combined to form a burner assembly, and the flame produced by the burner assembly is located at the In the combustion chamber, air wall holes 3 are provided around each of the thick-lean burners and each of the common burners. When the burner burns, the airflow passing through the air wall holes forms the burner assembly The wind wall 4 isolated from the combustion chamber.

[0016] It should be noted that the wind wall described in the present invention and the wind wall shown in the accompanying drawings are formed by the airflow passing through the uniformly arranged wind wall holes when the burner is burning, and the wind wall is not a part on the burner or in the combustion chamber .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com