Angle position detector

An angular position and detector technology, applied in the direction of angle/taper measurement, etc., can solve the problems of poor self-adaptation, single function of fixed angle detection tools, etc., and achieve the effect of reducing workload, flexible and convenient movement, and flexible and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

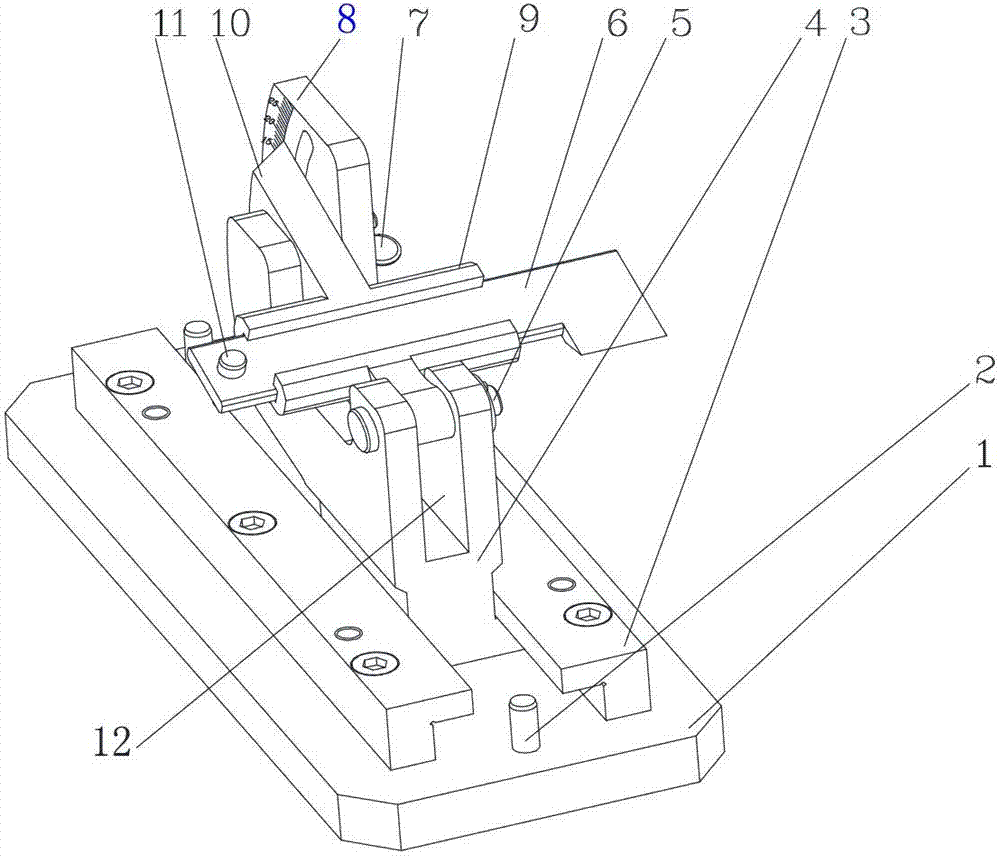

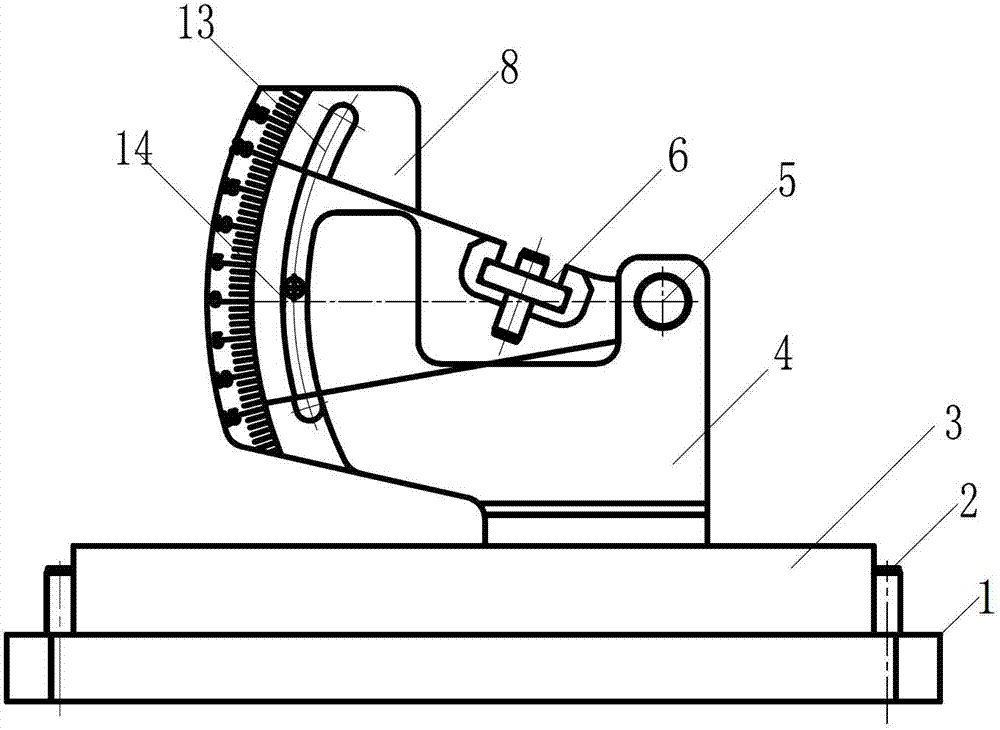

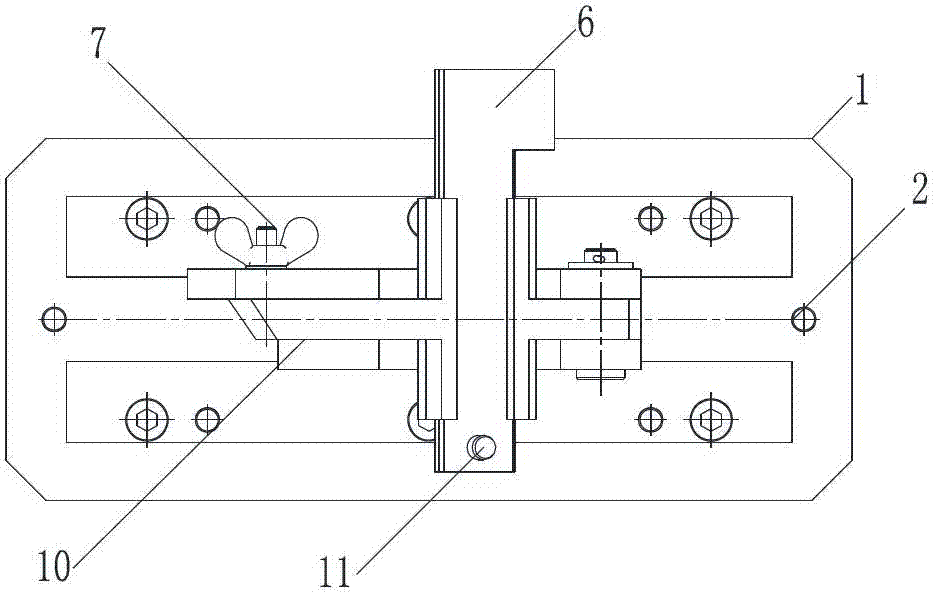

[0015] refer to Figure 1-Figure 3 . In an embodiment described below, the angular position detector has an angle measuring mechanism with a plank ruler 6, and the angle measuring mechanism includes a base plate 1 and a movable slide plate 4 vertical to the base plate 1, the base plate 1 is a support The plate body of mobile slide plate 4, this plate body can be a rectangular plate body, specifically a rectangular plate body, is shaped on the guide block 3 of symmetrical mobile slide plate 4, guide block 3 is positioned at along the longitudinal direction of cuboid The two sides of the mobile slide plate 4 are fixedly connected to the bottom plate 1 by bolts through the fastening holes arranged thereon to form a chute-type longitudinal guide rail mechanism with an inverted T shape. The mobile slide 4 with a T-shaped slider seat is perpendicular to the plane of the base plate 1 through the above-mentioned longitudinal guide rail mechanism, and has a degree of freedom of moveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com