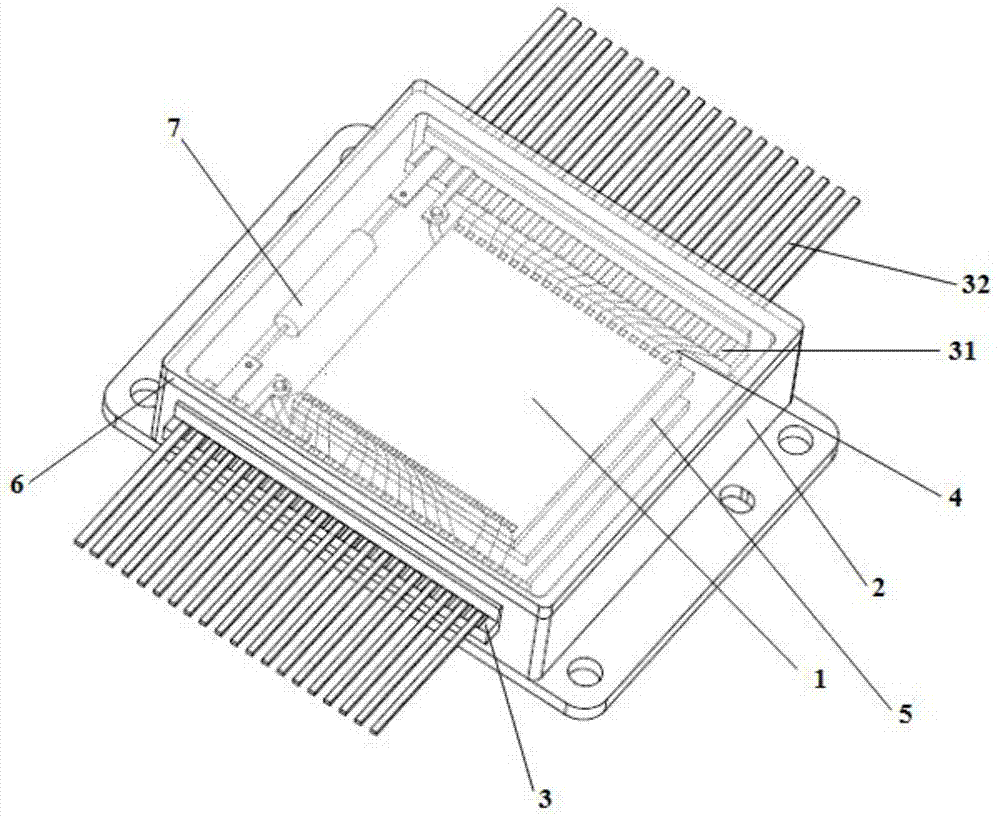

Chip packaging method and chip packaging structure

A chip packaging structure and chip packaging technology, applied in the direction of radiation control devices, etc., can solve problems such as inability to perform imaging functions, and achieve the effects of saving space, reducing packaging costs, and reliable working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

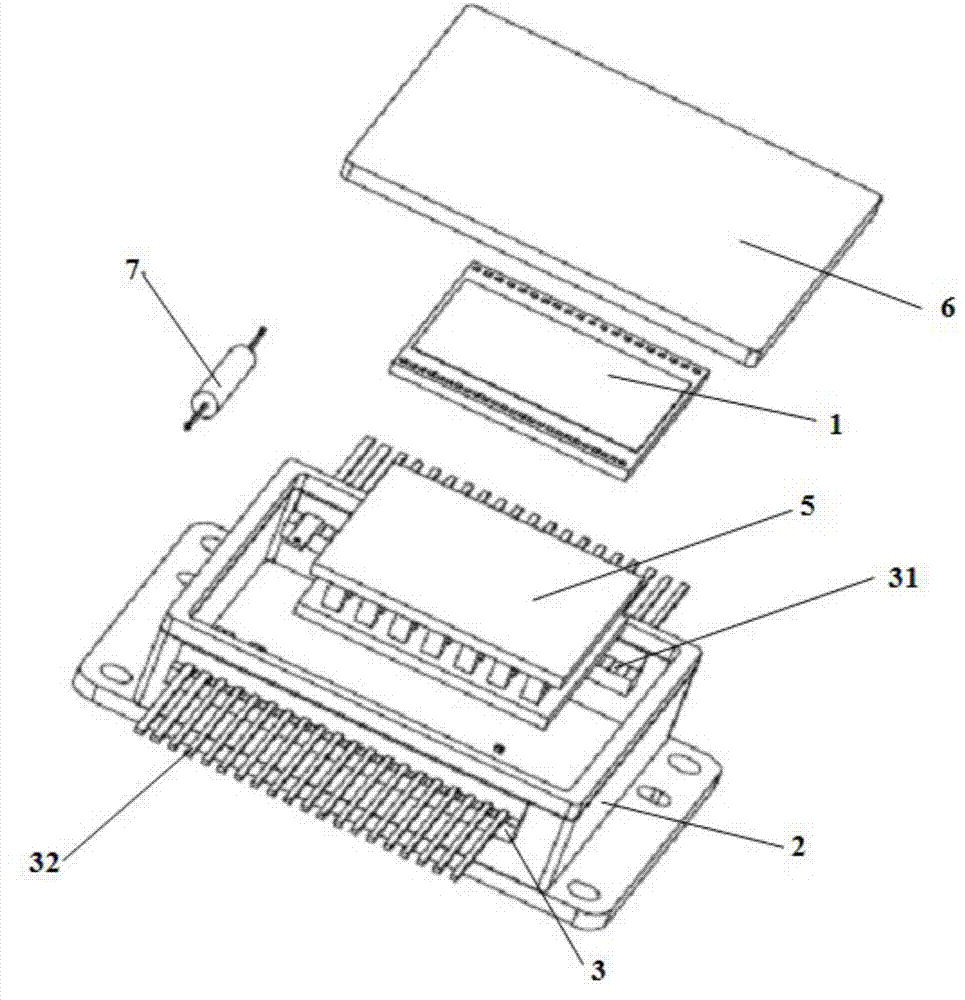

Embodiment Construction

[0043] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

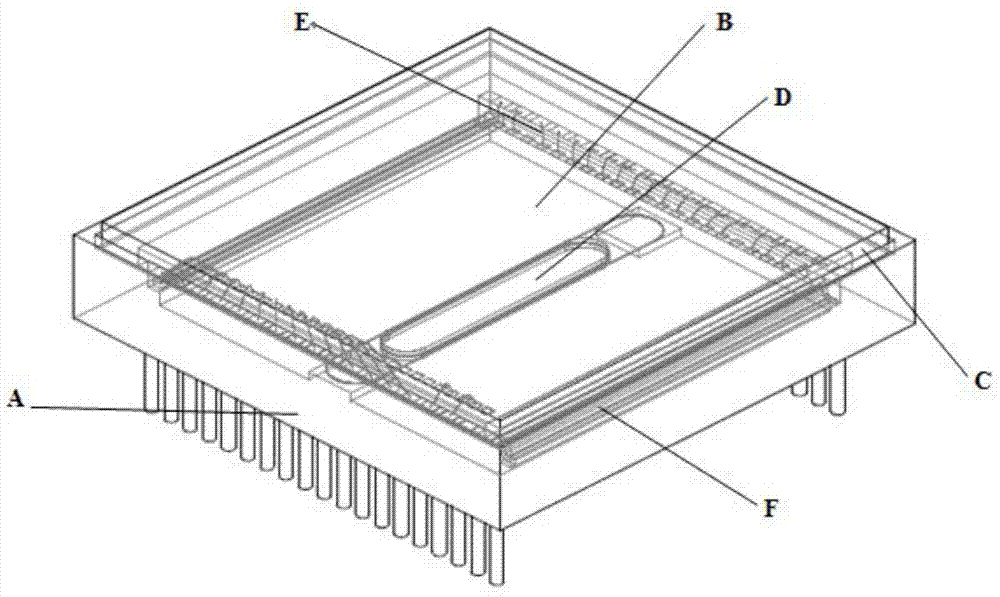

[0044] A kind of chip packaging method of the present invention, the steps are as follows: Figure 5 As shown, prepare a package case A, make the package case a rectangular cavity with an open top, make a step-type welding area A4 inside the opening of the package case, and make a step-type welding area A4 on both sides of the step-type welding area A4 A step A1 is made on the inner wall, pads A3 are installed on the inner walls of the other two sides of the step-shaped welding area A4, and the height of the pad A3 is greater than the height of the step, and the metal pin A5 located outside the package shell is connected to the pad A3 is electrically connected; two metal platforms A2 are installed on the inner botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com