Device for assembling two parts made from thermoplastic materials by means of laser-transparent welding and associated assembly method

A technology of laser transmission welding and assembly equipment, which is applied to household components, vehicle parts, transportation and packaging, etc. It can solve the problems of appearance quality defects, increase the price of assembly equipment, and complicate matters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

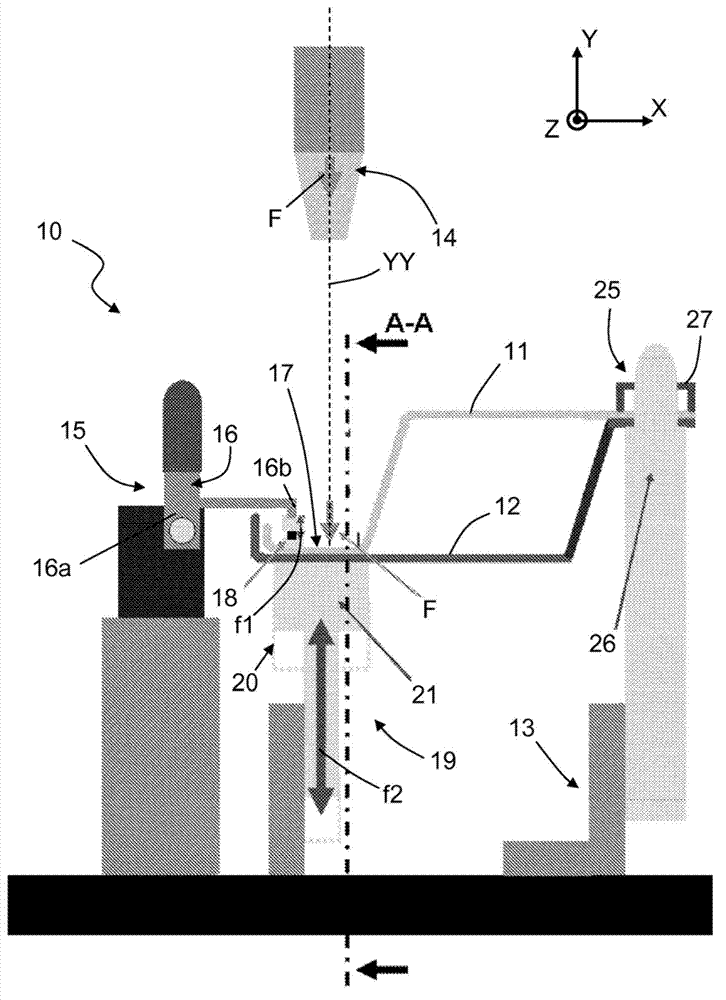

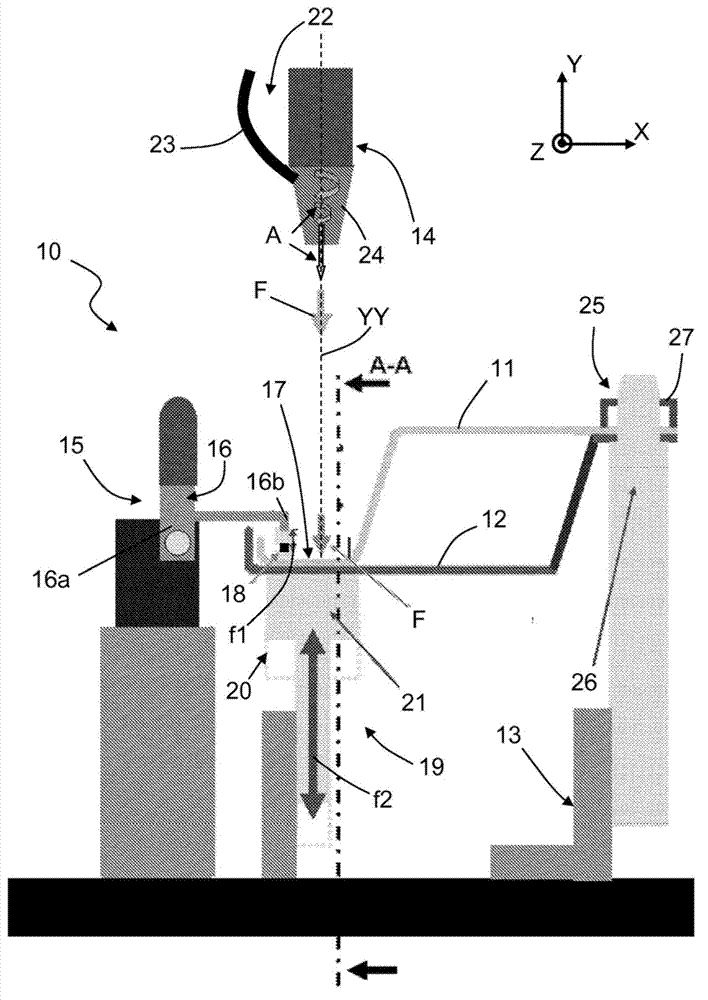

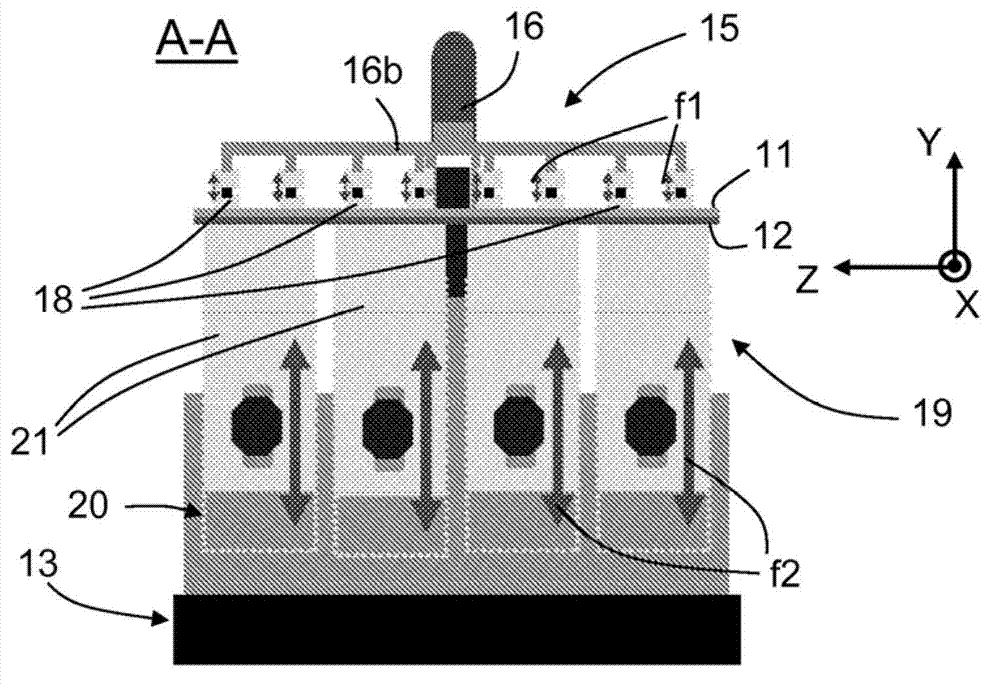

[0039] see Figure 1 to Figure 6, the assembly device 10 according to the invention is intended for assembling two fittings made of thermoplastic material by laser transmission welding. The assembly device 10 according to the invention takes into account more specifically the limiting factors related to the materials of the fittings to be assembled and to the associated laser welding method, namely the difference in materials and their rigidity, the fact that one of the two fittings is for example a cosmetic fitting and the bond must be perfect at the weld interface of the two fittings. More specifically, as Figure 4 and Figure 5 As indicated, the assembly device 10 according to the invention is, for example, intended to assemble a trunk lid or a tailgate of a motor vehicle.

[0040] In the following description, expressions such as "rear" and "front", "left" and "right", "top" and "bottom", and orientations of "portrait", "landscape" and "vertical" will be It is used by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com