Liquefaction method, liquefaction device, and floating liquefied gas production equipment comprising same

A liquefaction device, liquefied gas technology, applied in liquefaction, refrigeration and liquefaction, lighting and heating equipment and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

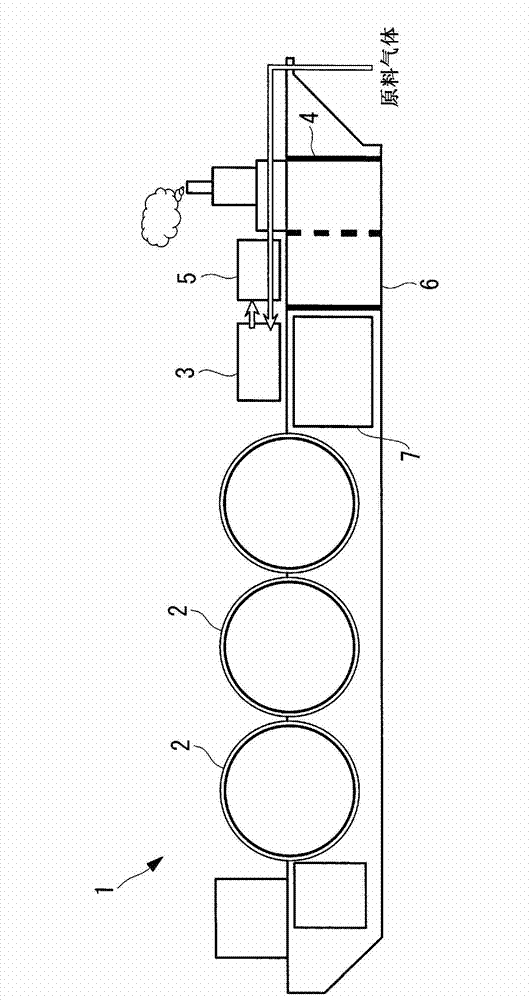

[0040] based on figure 1 , will describe a schematic configuration diagram of a floating liquefied gas production facility equipped with a liquefaction device according to an embodiment of the present invention.

[0041] Floating LNG manufacturing facility (Floating LNG: FLNG) 1 includes: multiple cargo tanks 2 for storing liquefied natural gas (liquefied gas); pre-processing device 3; liquefaction device (not shown); floating LNG manufacturing facility 1 A power supply device (not shown) for internally supplying electric power.

[0042] Floating liquefied natural gas manufacturing facility (floating liquefied natural gas manufacturing facility) 1 refines and liquefies raw gas (liquefied gas) that is ejected at high pressure from land or under the seabed to form liquefied natural gas (liquefied gas) as a product natural gas: LNG), and set on the ocean.

[0043] Cargo tanks (in this figure, only 3 are shown) 2 store LNG. Cargo tank 2 is a MOSS independent spherical tank.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com