Fluid iron removal method and device

A technology of fluid and ferromagnetic substances, applied in the field of fluid iron removal technology, can solve the problems of large amount of ferromagnetic substances in the residual slurry, difficult to handle, unsatisfactory iron removal effect, etc., and achieve the effect of less residual slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

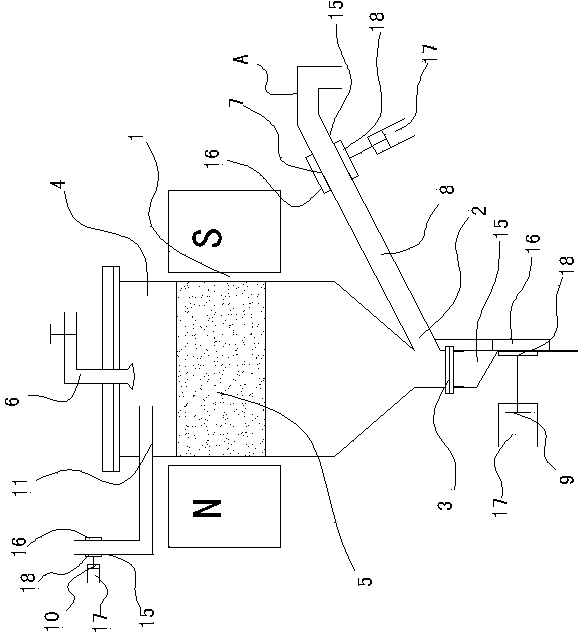

[0014] Embodiment 1: as figure 1 As shown, the fluid iron removal device of the present invention includes a magnetic field 1 formed by the opposite poles of an electromagnetic device or a permanent magnet, a channel 4 made of a non-magnetic material with a finished product outlet 2 and a waste slurry discharge port 3, and a set The soft magnetic medium 5 in the middle and upper part of the channel 4 is provided with a cleaning liquid spraying device 6 and a fluid inlet 11 with a valve 10 at the upper entrance of the channel 4. The special feature is that the finished product outlet 2 with the valve 7 is located at On the side below the channel 4, the finished product outlet 2 is connected with an upwardly inclined conduit 8, the highest point A of the conduit 8 is located below the soft magnetic medium 5, and the waste slurry discharge port 3 with a valve 9 is located at the bottom of the channel 4. The valve 10 on the fluid inlet 11 and the valve 7 on the finished product ou...

Embodiment 2

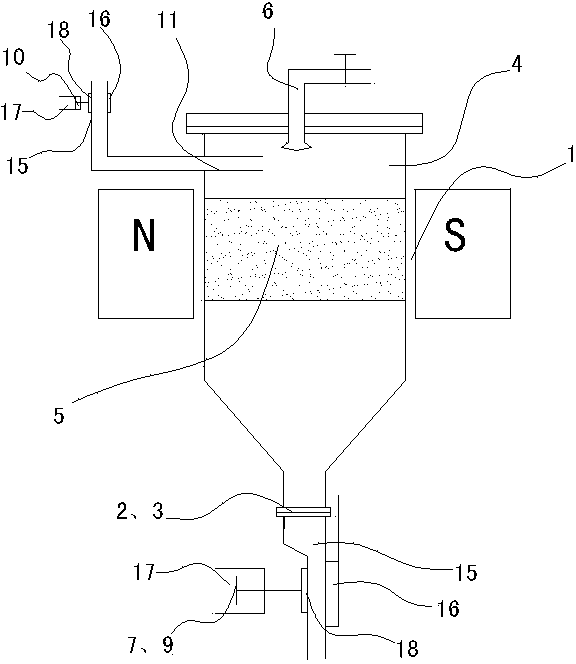

[0016] Embodiment 2: as figure 2 As shown, this embodiment is based on Embodiment 1, the finished product outlet 2 and the waste slurry discharge port 3 are the same outlet, and the valves 7 and 9 on the outlets 2 and 3 include hoses 15 and valves arranged on the hoses 15. The block 16 on one side and the pressing block 18 driven by the cylinder 17 are arranged on the other side of the hose 16. The block 16 moves synchronously with the movement of the channel 4 .

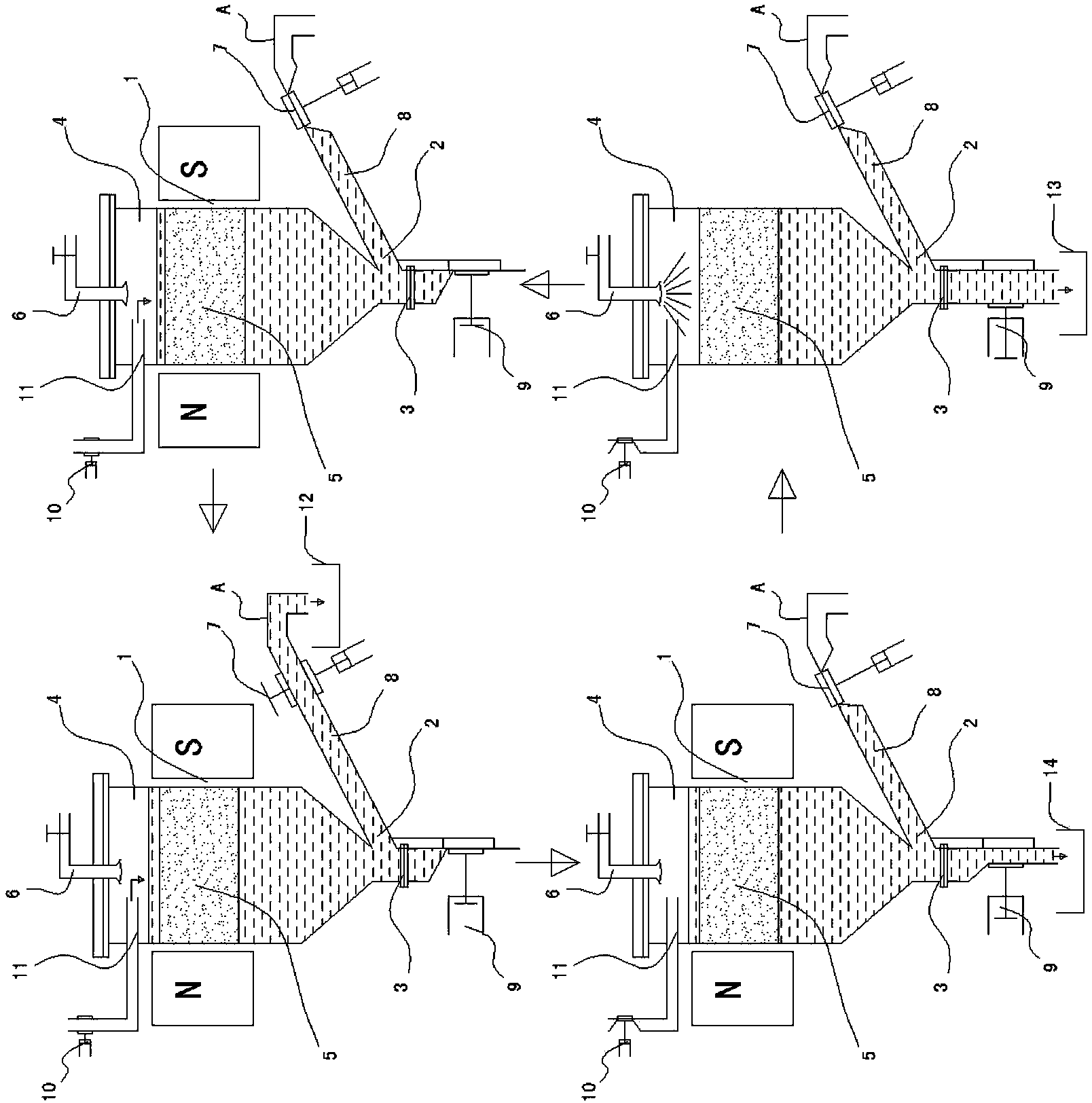

[0017] Such as image 3 As shown, the fluid iron removal method of the present invention is realized in this way, including the fluid iron removal process and the soft magnetic medium cleaning process. The channel 4 of the magnetic medium 5, the fluid after removing the ferromagnetic substance is introduced into the finished product collection container 12, and its special feature is that when the fluid in the process of removing the ferromagnetic substance starts to be introduced into the vertical channel 4 from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com