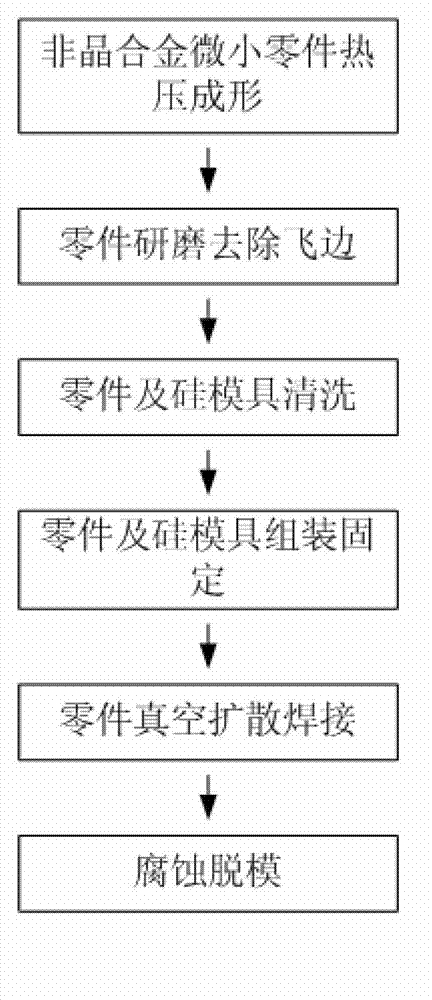

Method for manufacturing preparing multilayer amorphous alloy micro part by vacuum diffusion welding

A technology of vacuum diffusion welding and amorphous alloys, which is applied in welding equipment, non-electric welding equipment, manufacturing tools, etc., can solve problems such as the difficulty in forming small parts of multilayer amorphous alloys, and achieve easy promotion and use, expansion of application range, connection Sophisticated and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

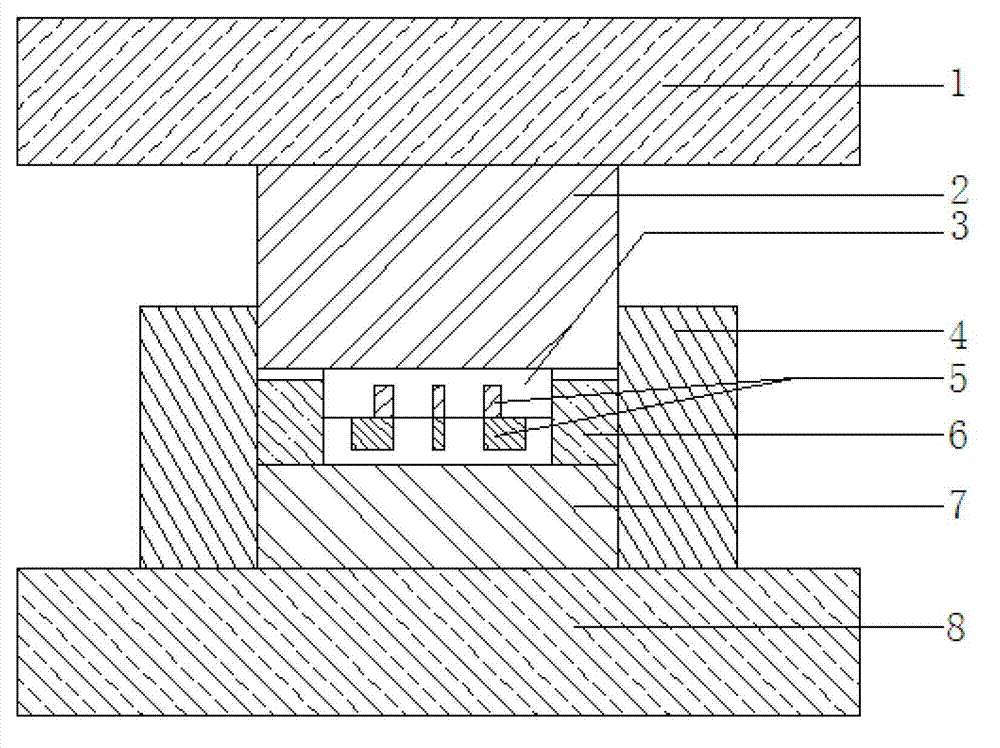

Embodiment 1

[0061] Will Zr 41 Ti 14 Cu 12.5 Ni 10 be 22.5 The thin plate is cut into a block with a size of 4×4×1mm, the forming parameters of the pressure forming machine are set, the cut plate is placed on the silicon mold, and then the whole is put into the pressure forming machine and hot-pressed into tiny parts of amorphous alloy . Fix the formed amorphous alloy tiny parts and silicon mold as a whole, and use sandpaper and polishing cloth with a particle size of 800#, 1000#, and 1200# on the grinder to grind and polish the flash end face until the flash and surface oxide layer are completely removed , to obtain a welded surface. Then immerse the parts and silicon molds after the flash removal in acetone for 15min to 30min and ultrasonically clean them for 15-30min, take them out and put them in a container filled with absolute ethanol for a second ultrasonic cleaning for 15min, and put the cleaned parts and silicon molds Store in clean absolute ethanol. Use the silicon mold pr...

Embodiment 2

[0063] Will Zr 41 Ti 14 Cu 12.5 Ni 10 be 22.5 The thin plate is cut into blocks with a size of 4×4×1mm, the forming parameters of the pressure forming machine are set, the cut plate is placed on the silicon mold, and then the whole is put into the pressure forming machine to form amorphous alloy tiny parts. Fix the formed part and the silicon mold as a whole, and use sandpaper and polishing cloth with a particle size of 800#, 1000#, and 1200# on the grinder to grind and polish the flash end face until the flash and surface oxide layer are completely removed, and the strip welding is obtained. noodle. Then immerse the parts and silicon molds after the flash removal in acetone for 15min to 30min and ultrasonically clean them for 15-30min, take them out and put them in a container filled with absolute ethanol for a second ultrasonic cleaning for 15min, and put the cleaned parts and silicon molds Store in clean absolute ethanol. Use the silicon mold protective sleeve to fix ...

Embodiment 3

[0065] Will Zr 55 Cu 30 Al 10 Ni 5 The thin plate is cut into blocks with a size of 4×4×1mm, the forming parameters of the pressure forming machine are set, the cut plate is placed on the silicon mold, and then the whole is put into the pressure forming machine to form amorphous alloy tiny parts. Fix the formed part and the silicon mold as a whole, and use sandpaper and polishing cloth with a particle size of 800#, 1000#, and 1200# on the grinder to grind and polish the flash end face until the flash and surface oxide layer are completely removed, and the strip welding is obtained. noodle. Then immerse the parts and silicon molds after the flash removal in acetone for 15min to 30min and ultrasonically clean them for 15-30min, take them out and put them in a container filled with absolute ethanol for a second ultrasonic cleaning for 15min, and put the cleaned parts and silicon molds Store in clean absolute ethanol. Use the silicon mold protective sleeve to fix and protect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com