Stainless steel plate 8K mirror surface processing method

A mirror surface processing, stainless steel technology, applied in metal processing equipment, manufacturing tools, surface polishing machine tools, etc., can solve the problems of large thermal deformation, difficult to remove impurities, etc., achieve good anti-corrosion effect, high finish, and bright mirror effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Water washing Place the stainless steel plate 4 on the polishing platform, and clean the sundries on the surface of the stainless steel plate 4 with clean water.

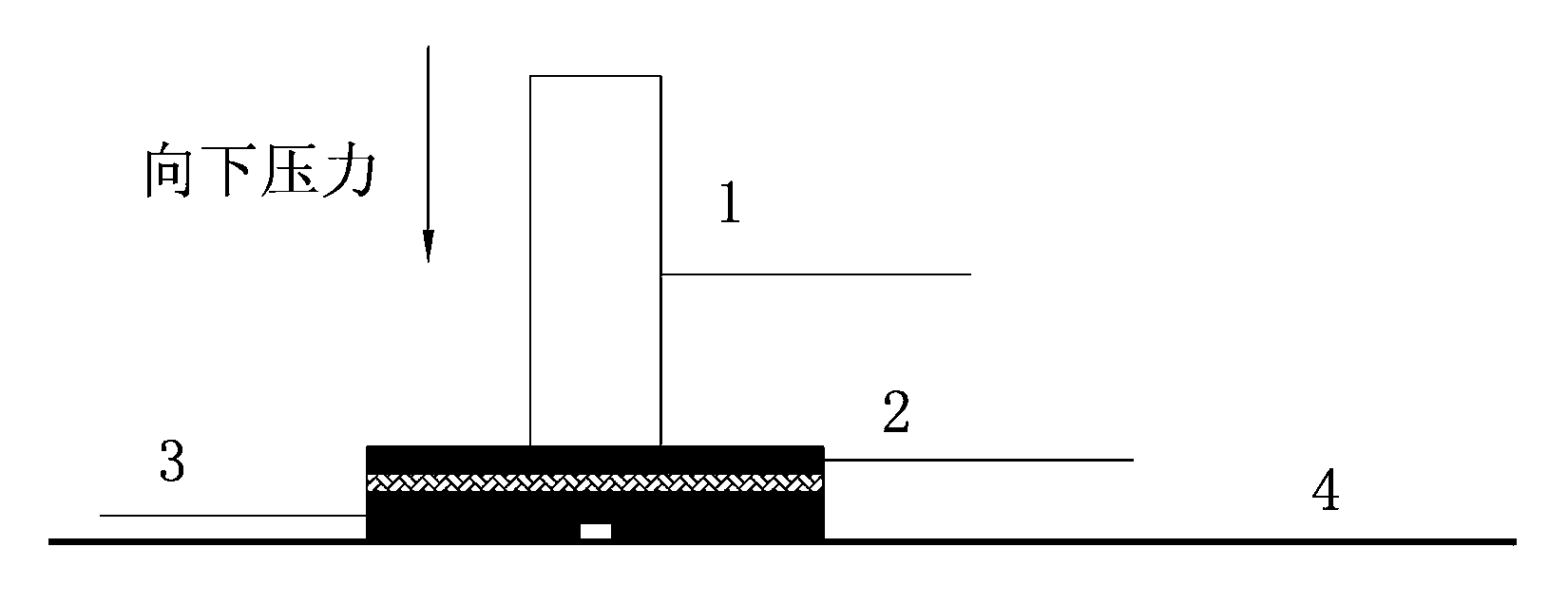

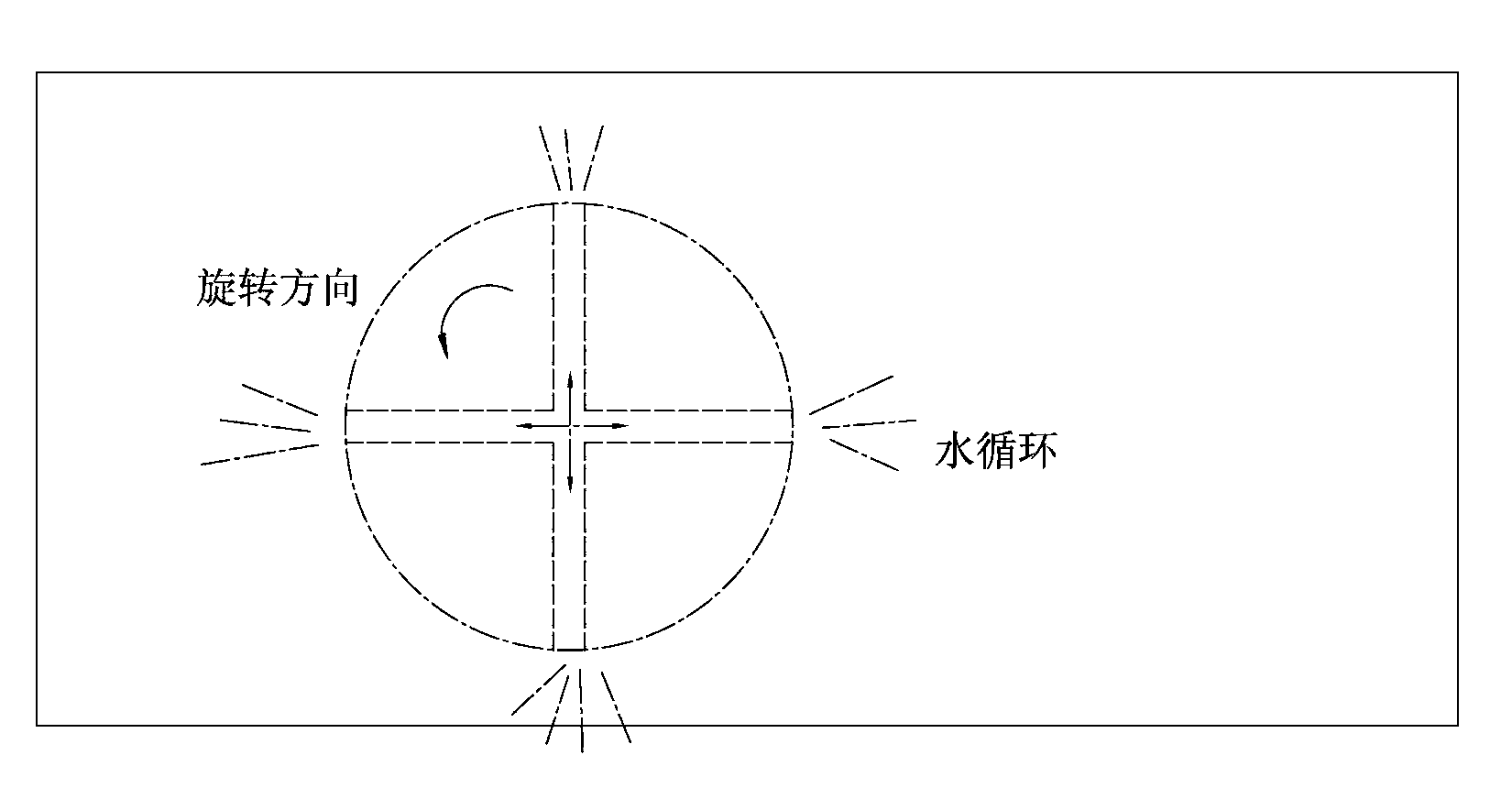

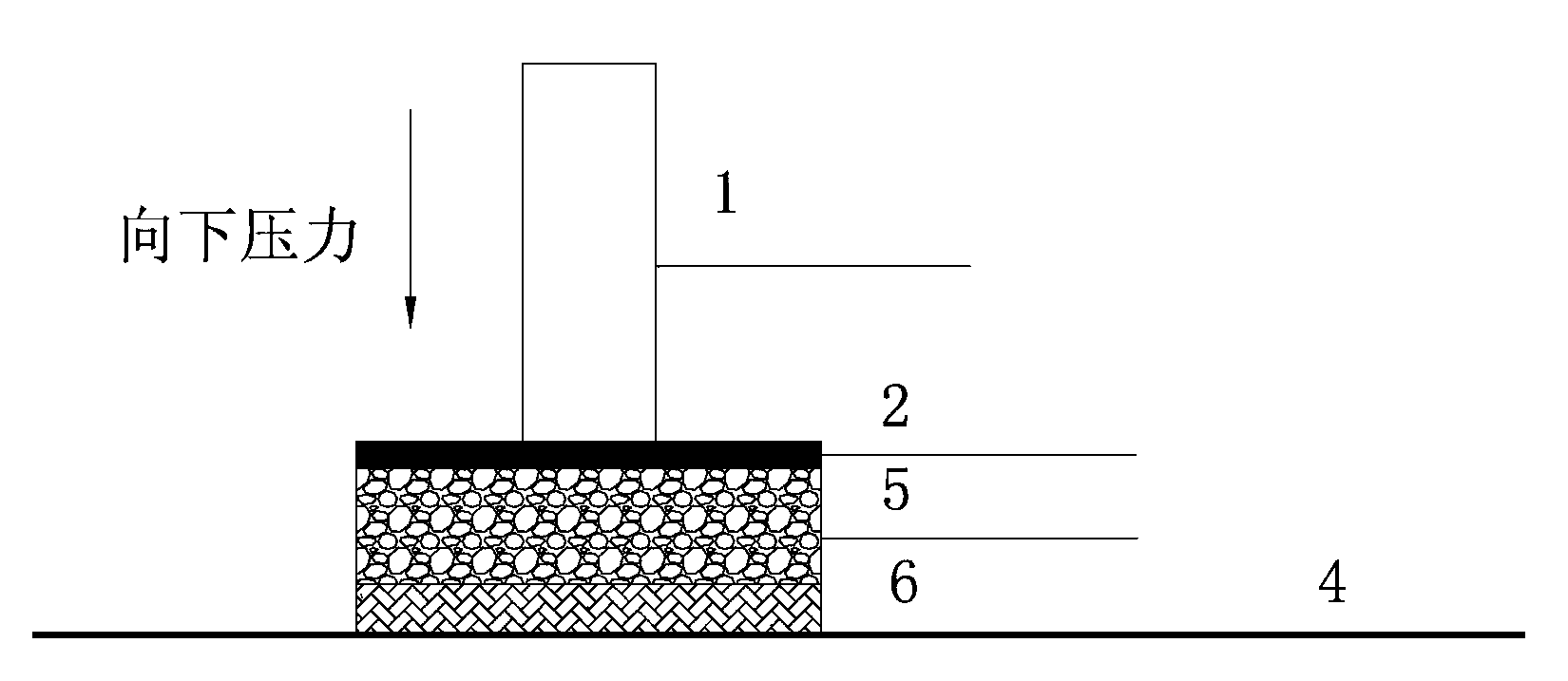

[0020] 2. Rough polishing (see figure 2 ), use a graphite wheel to grind the stainless steel plate surface 4, the processing method is the cross method, first uniformly grind once in the longitudinal direction, and then uniformly grind once in the horizontal direction to ensure that the grinding direction is always consistent, and the grinding feed speed is 1.5M / min. The grinding gap is half the diameter of the grinding wheel until the surface is uniform and pit-free. The spindle speed is 40r / min. The coarse polishing abrasive tool is composed of a main shaft 1, a grinding holder 2, and a graphite wheel 3 (see figure 1 ), the main shaft 1 is driven by a motor, and one end of the main shaft is connected with the grinding plate. The grinding plate is made of 16mm steel plate, and the graphite wheel ...

Embodiment 2

[0028] 1. Water washing Place the stainless steel plate 4 on the polishing platform, and clean the sundries on the surface of the stainless steel plate 4 with clean water.

[0029] 2. Rough polishing (see figure 2 ), use a graphite wheel to grind the stainless steel plate surface 4, the treatment method is the cross method, first grind evenly in the longitudinal direction, and then grind evenly in the horizontal direction to ensure that the grinding direction is always consistent, and the grinding feed speed is 2M / min. The grinding gap is half the diameter of the grinding wheel until the surface is uniform and pit-free. The spindle speed is 50r / min. The coarse polishing abrasive tool is composed of a main shaft 1, a grinding holder 2, and a graphite wheel 3 (see figure 1 ), the main shaft 1 is driven by a motor, and one end of the main shaft is connected with the grinding plate. The grinding plate is made of 16mm steel plate, and the graphite wheel is glued to the gri...

Embodiment 3

[0037] 1. Water washing Place the stainless steel plate 4 on the polishing platform, and clean the sundries on the surface of the stainless steel plate 4 with clean water.

[0038] 2. Rough polishing (see figure 2 ), use a graphite wheel to grind the stainless steel plate surface 4, the treatment method is the cross method, first grind evenly in the longitudinal direction, and then grind evenly in the horizontal direction to ensure that the grinding direction is always consistent, and the grinding feed speed is 2M / min. The grinding gap is half the diameter of the grinding wheel until the surface is uniform and pit-free. The spindle speed is 45r / min. The coarse polishing abrasive tool is composed of a main shaft 1, a grinding holder 2, and a graphite wheel 3 (see figure 1 ), the main shaft 1 is driven by a motor, and one end of the main shaft is connected with the grinding plate. The grinding plate is made of 16mm steel plate, and the graphite wheel is glued to the gri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com