Thermal transfer device

A technology of thermal transfer printing and rotating device, applied in transfer printing, rotary printing machine, printing and other directions, can solve the problems of printing deviation, low production efficiency, affecting product quality, etc., to improve production efficiency, simplify production process, avoid Effects of Thermal Transfer Quality Issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

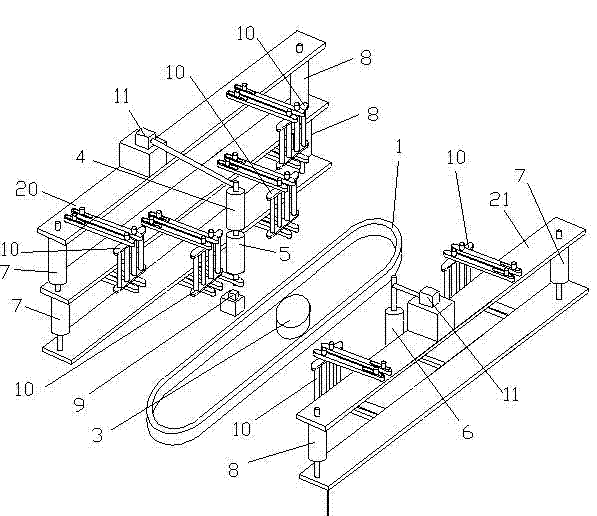

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] like figure 1 As shown, a thermal transfer device includes a conveyor belt 1, a first fixed seat 20 and a second fixed seat 21 are installed on both sides of the transmission belt 1, and an upper heating roller coaxially arranged on the first fixed seat 20 is installed. 4 and the middle heating roller 5, the lower heating roller 6 corresponding to the position of the upper heating roller 4 and the middle heating roller 5 is installed on the second fixed seat 21, the upper heating roller 4, the middle heating roller 5, The lower heating rollers 6 are at different heights in the same plane. When it is necessary to carry out thermal transfer printing on the drum body, the steel drum is processed by the upper heating roller 4, the middle heating roller 5, and the lower heating roller 6 at the same time, which realizes the simultaneous printing of the middle and low...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap