Paper sludge transfer and storage silo

A papermaking sludge and storage silo technology, applied in the directions of transportation and packaging, loading/unloading, containers, etc., can solve the problems of material blockage at the outlet of the sludge storage hopper, increased labor costs, high viscosity, etc., and achieves high service life. Avoid bridging and high blanking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

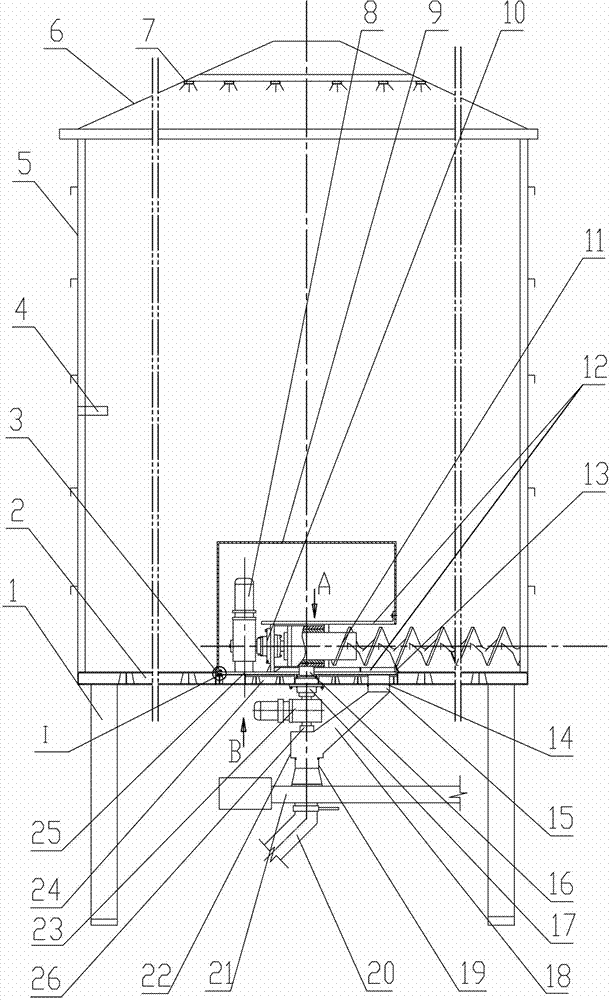

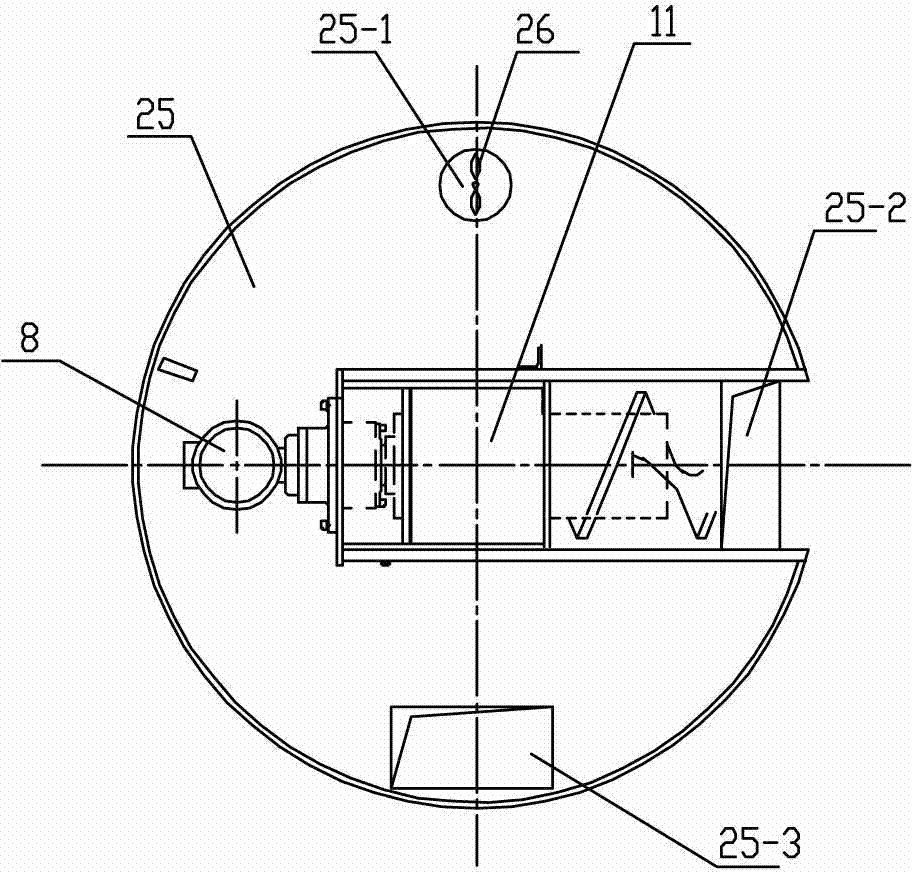

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

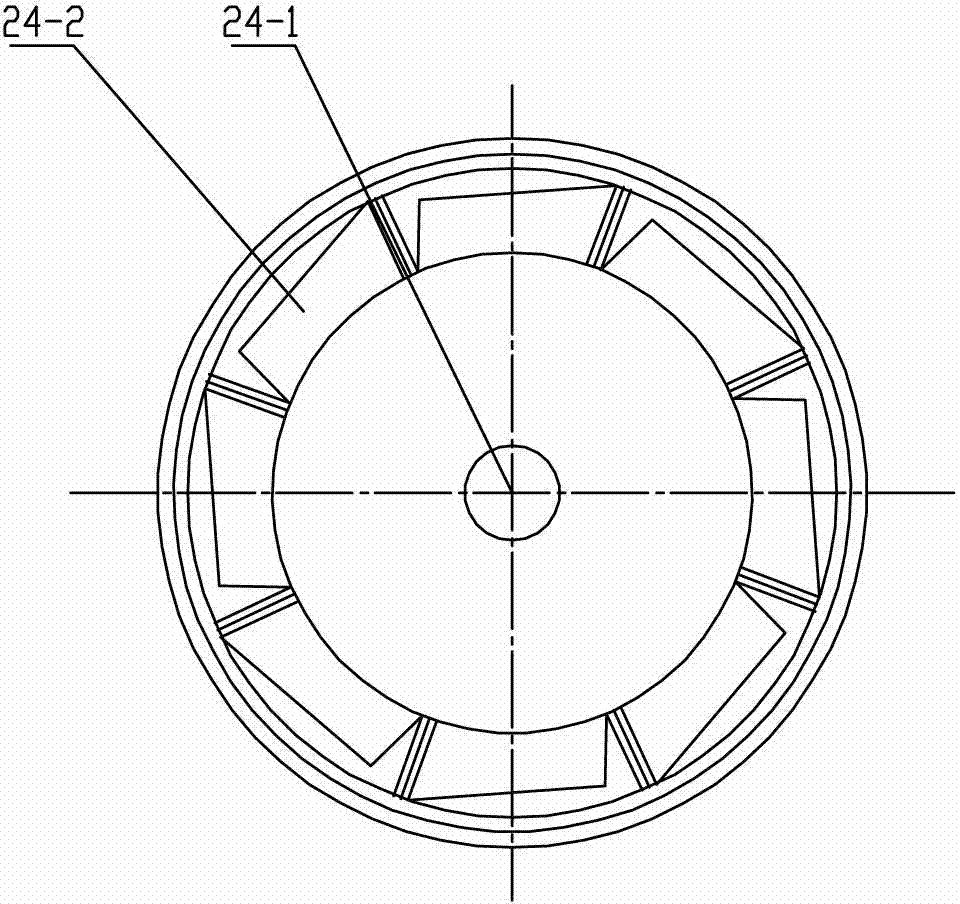

[0026] Such as figure 1 As shown, the papermaking sludge transfer storage bin of the present invention is characterized in that: it includes a closed bin body with a cylindrical inner cavity, a screw feeder and a bottom axial flow fan arranged on the bottom of the closed bin body, A group of fire extinguishing nozzles 7 arranged on the top of the closed warehouse body, a material level gauge 4 arranged in the middle of the closed warehouse body, a double-end output driving device 23 arranged on the bottom of the closed warehouse body, and the double-ended The discharge chute connected to the output lower end of the output driving device 23, the belt feeding hopper 19 that is slidingly connected with the bottom of the discharge chute, the belt conveyor 21 that is located below the belt feeding hopper 19 and the belt conveyor that is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com