Patents

Literature

32results about How to "Make sure not to exceed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for decreasing nitrate salts content of vegetable in greenhouse

InactiveCN101103685AReduce nitrate levelsIncrease productionFertilising methodsHorticulture methodsChemical reactionNitrate salts

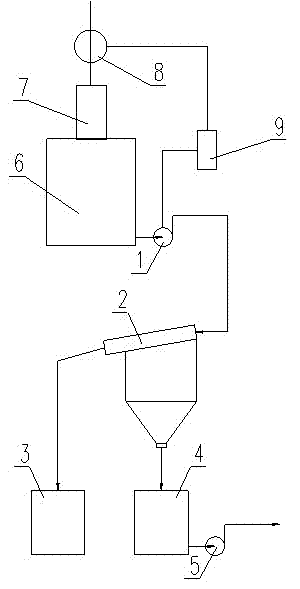

The invention discloses a method to reduce the nitrate content in greenhouse vegetables. In the entire cultivation period of greenhouse vegetables, the agricultural organic waste fermentation method is utilized for the greenhouse carbon dioxide fertilization to maintain the CO2 concentration within the greenhouse from 750 to 850 u l / L. Or from one week before the harvesting of the greenhouse vegetables until the time of harvesting, the agricultural organic waste fermentation method is utilized for the greenhouse carbon dioxide fertilization in short term to maintain the CO2 concentration within the greenhouse from 750 to 850 u l / L. Or from one week before the harvesting of the greenhouse vegetables until the time of harvesting, the chemical reaction method is adopted for the greenhouse carbon dioxide fertilization in short term to maintain the CO2 concentration within the greenhouse from 950 to 1050 u l / L. By the use of the method of the invention, the nitrate content in vegetables can be quickly and effectively reduced.

Owner:ZHEJIANG UNIV

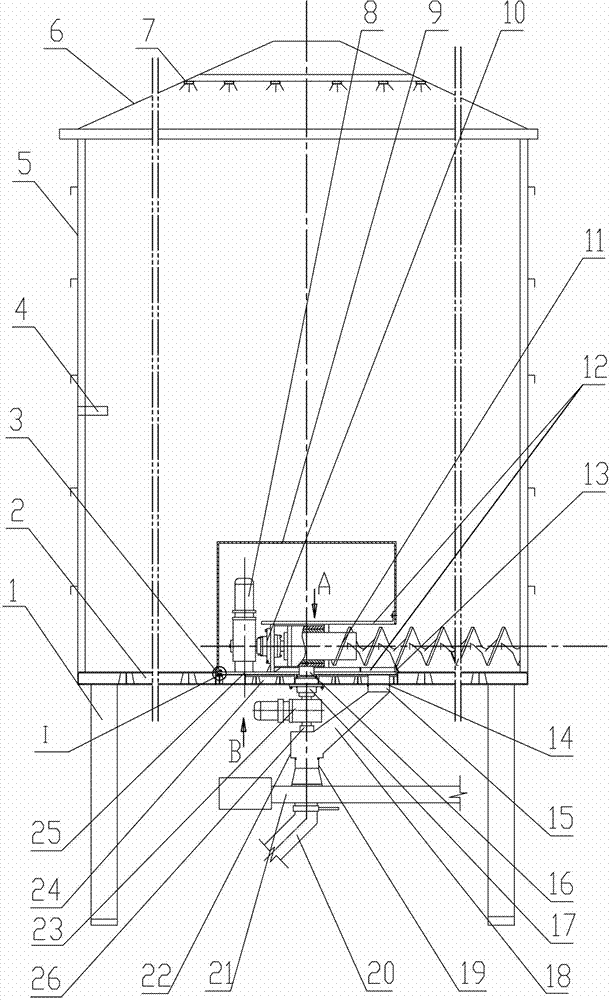

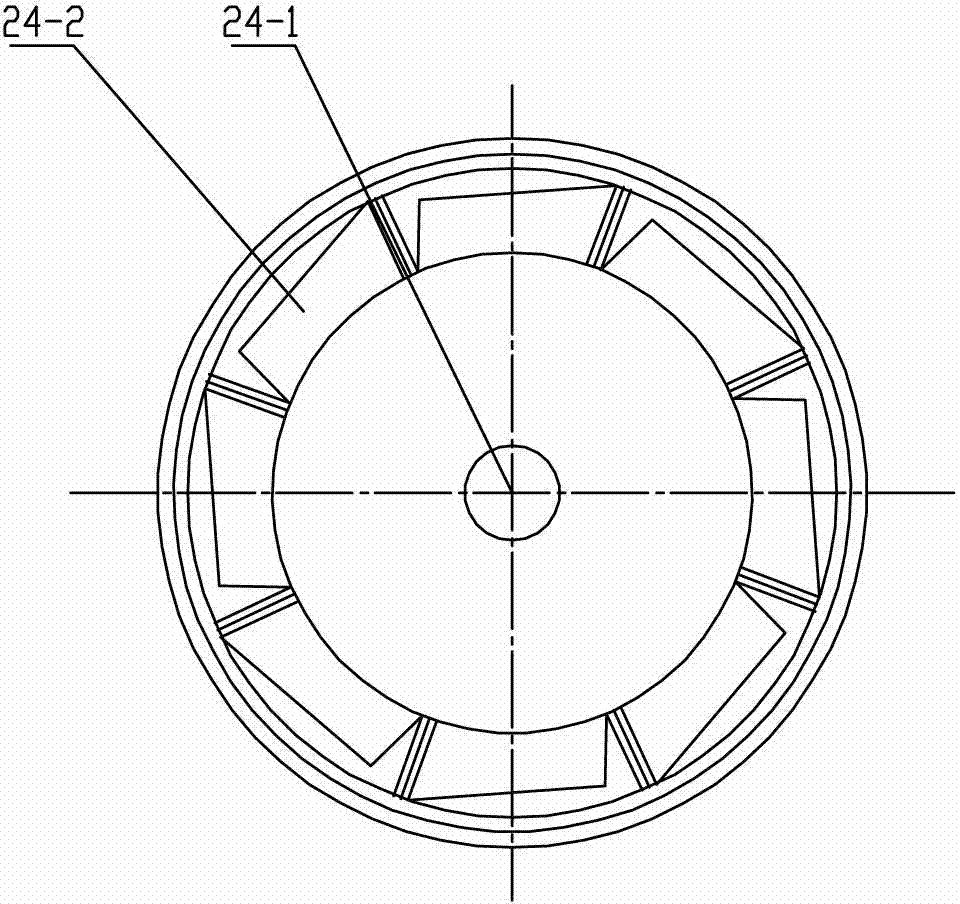

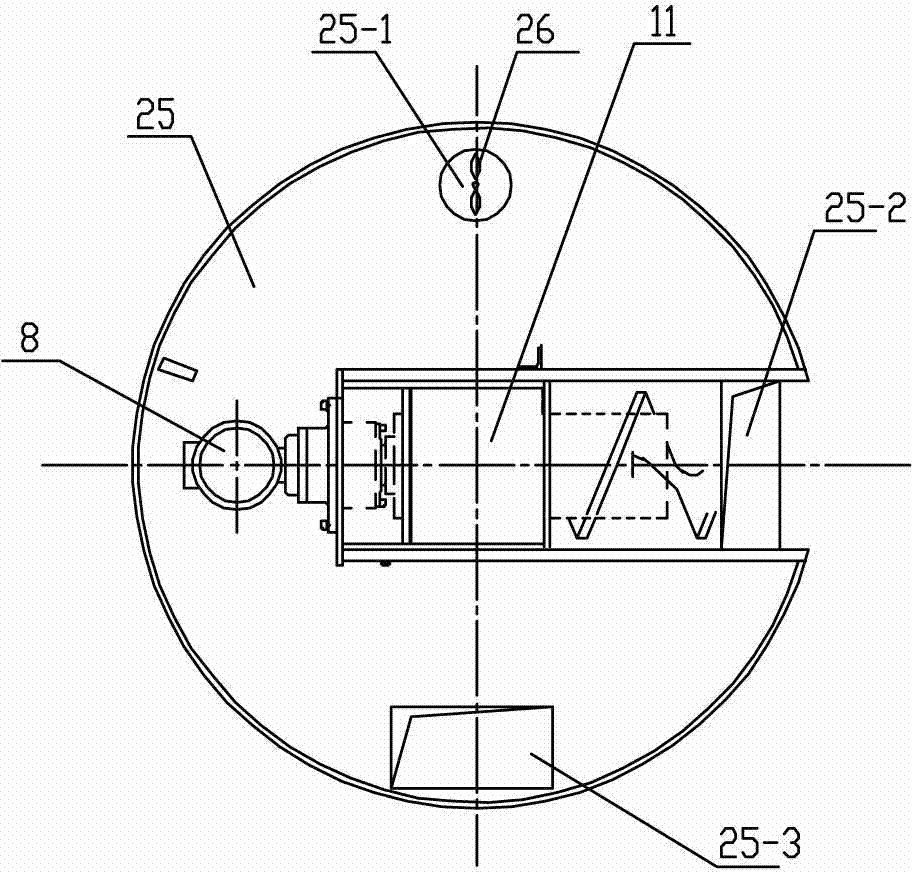

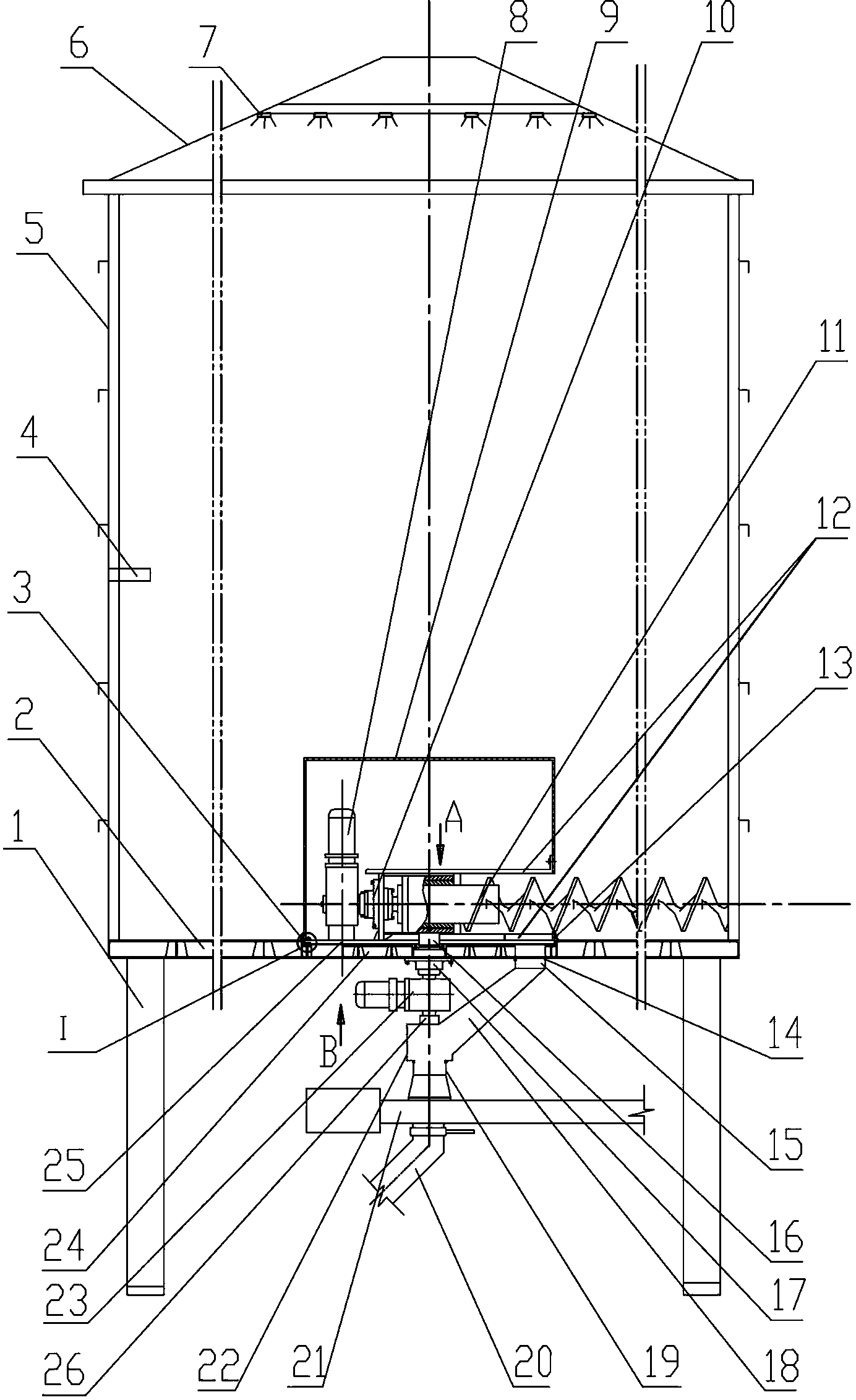

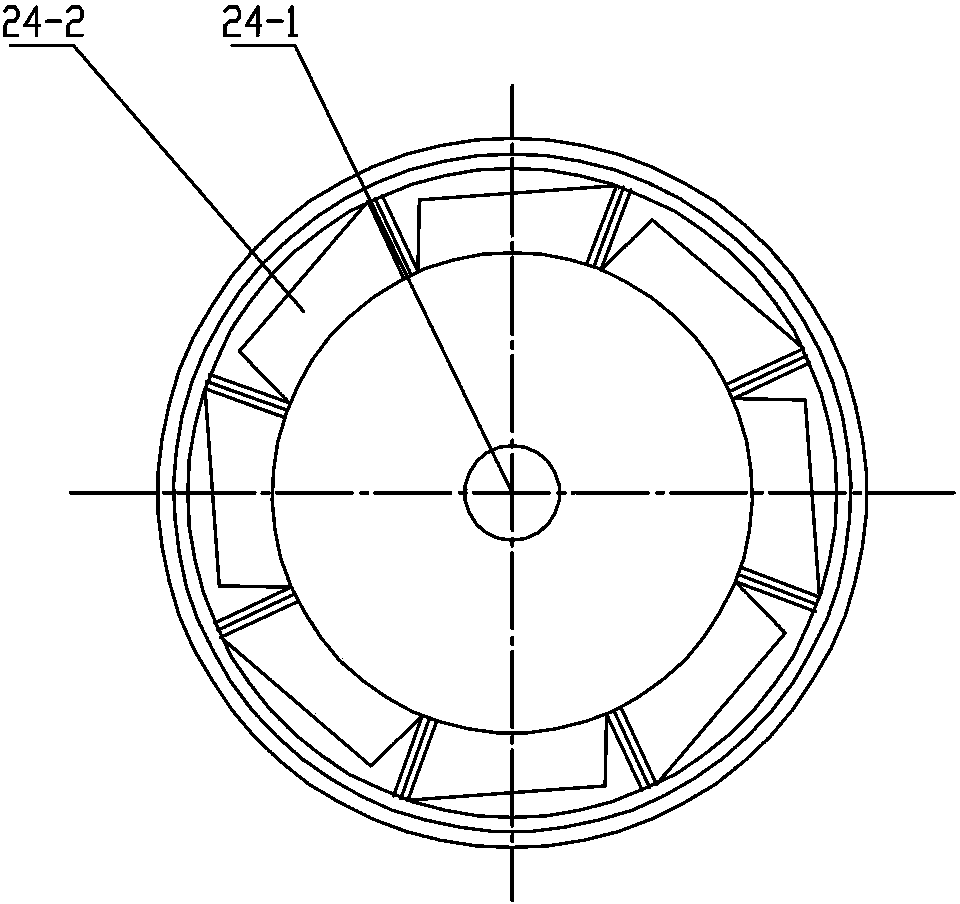

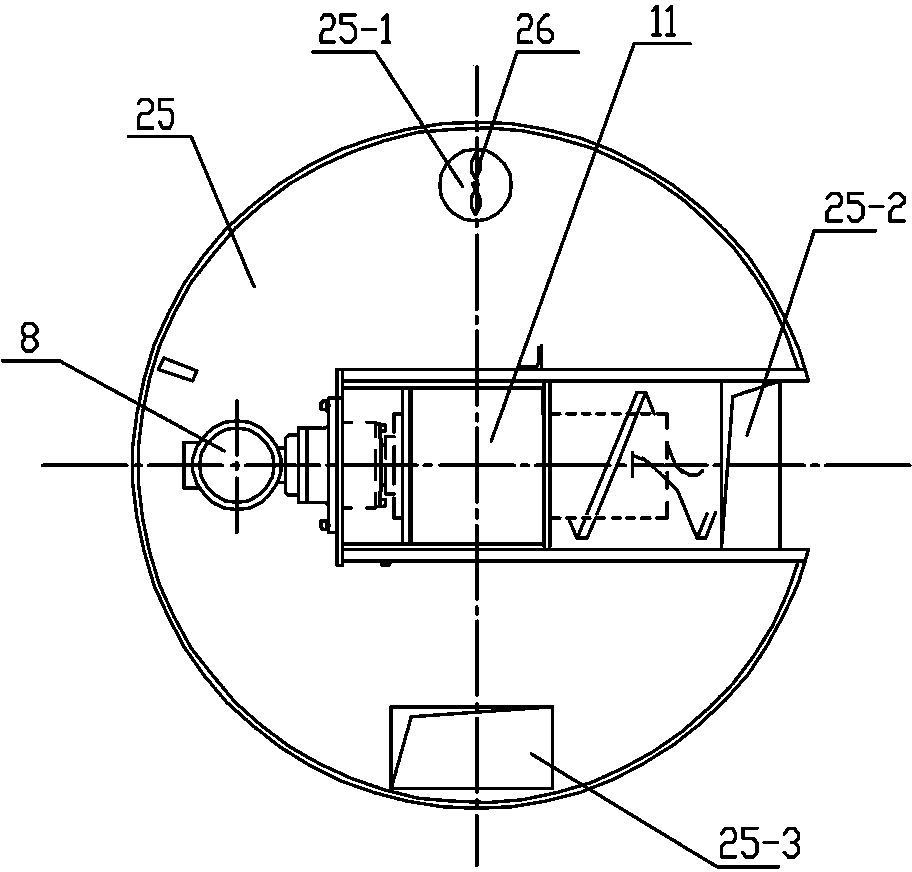

Paper sludge transfer and storage silo

ActiveCN102963633AExtended service lifeSmooth rotationLarge containersLoading/unloadingPulp and paper industrySliding contact

The invention belongs to the technical field of a paper sludge incineration device, and particularly relates to a paper sludge transfer and storage silo, which comprises a sealed silo body, a screw feeder, a bottom axial-flow fan, a group of fire fighting nozzles, a material level meter, a double-end output drive device, a discharging chute, a belt feeding hopper, a belt conveyor and an accident ash-discharging pipe. The sealed silo body consists of a steel structural framework, a combined disc type bottom plate, a cylindrical silo wall and an umbrella-shaped silo roof, wherein the combined disc type bottom plate consists of a fixed disc, a rotary disc, a vertical rotating shaft and a base bracket, the fixed disc consists of a ring-shaped fixed plate, a central fixed plate and a ring-shaped power supply sliding contact line, and the rotary disc is provided with a sludge outlet, a ventilating manhole and a mounting hole. The sealed silo body is suitable for rotation and mixing of materials in the silo and the service life of the silo body is long. The screw feeder has the functions of revolution and rotation. Materials can be delivered into an appropriate position due to rotation while being mixed under effects of revolution, the problem of bypass of sludge materials can be avoided, and the efficiency of transfer and falling is high.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

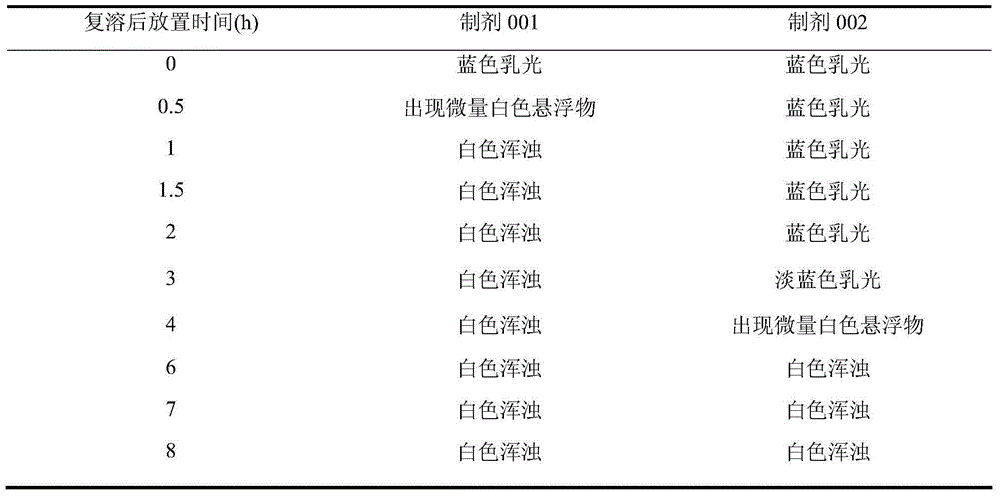

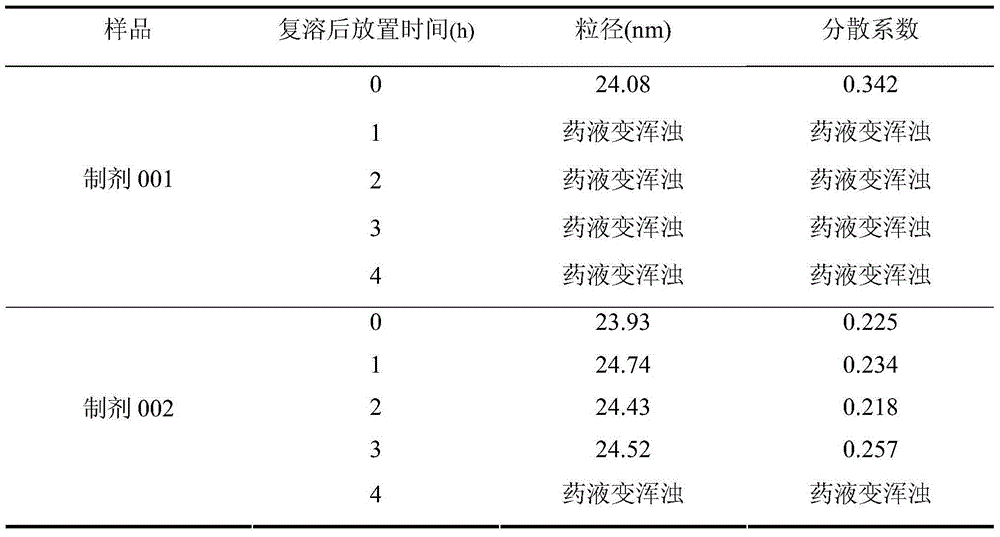

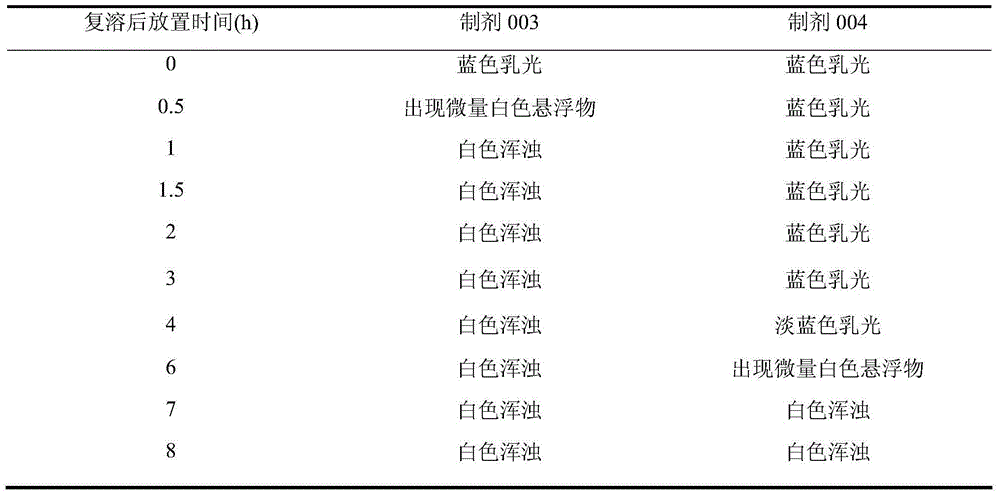

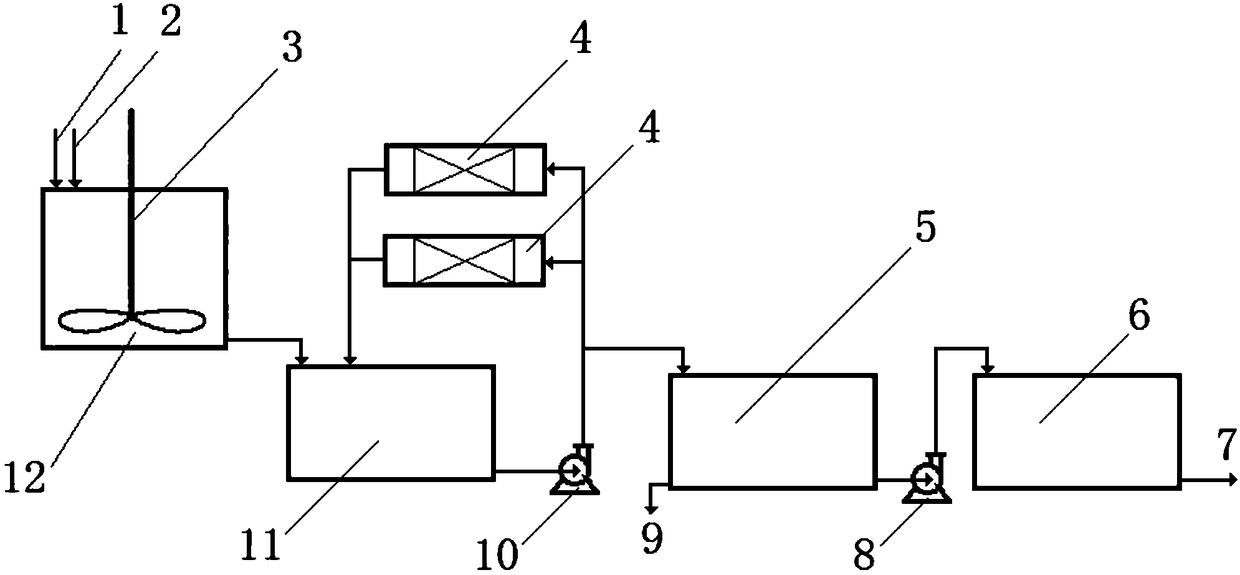

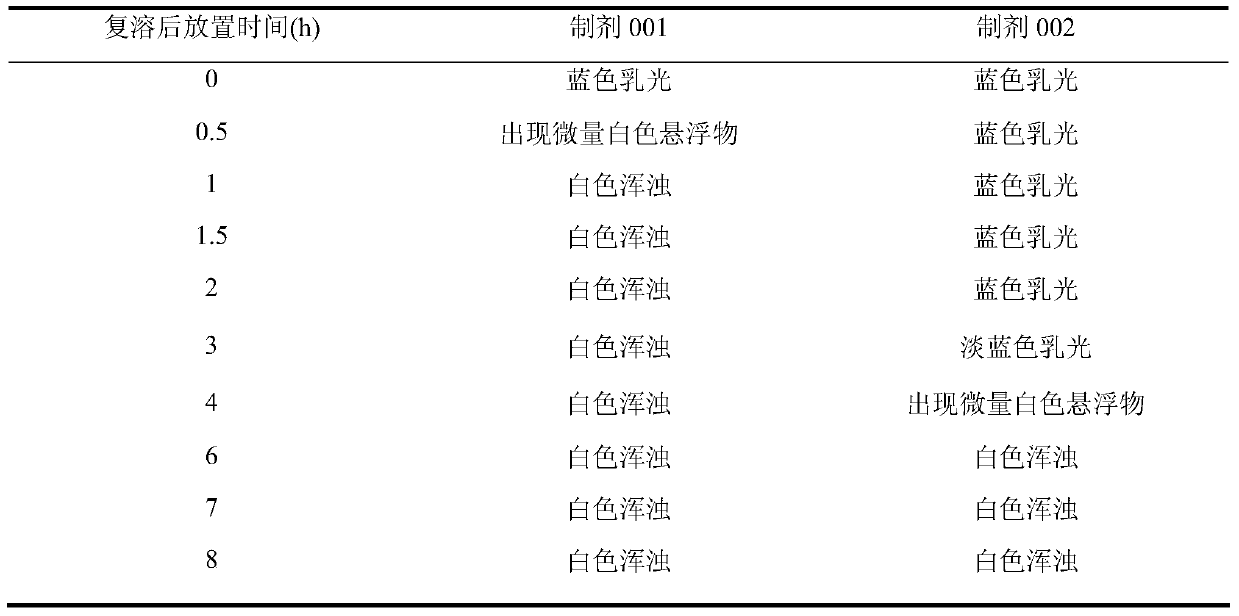

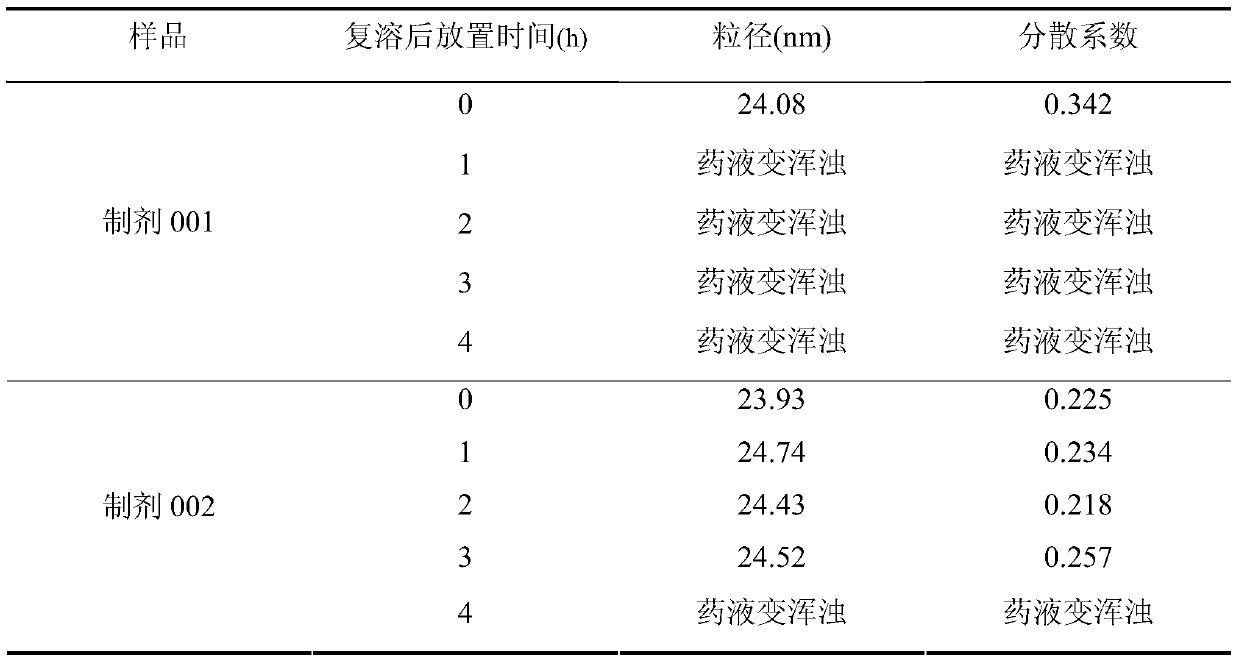

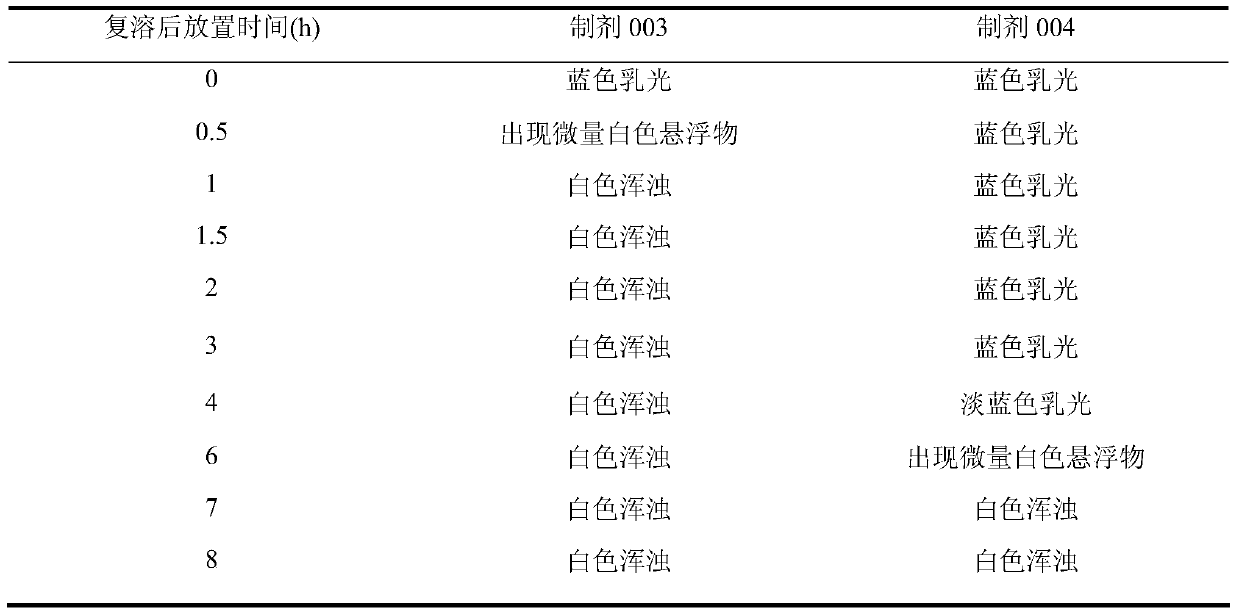

Purification method of polyethylene glycol monomethyl ether-polylactic acid amphiphilic segmented copolymer for injection

ActiveCN105315444AReduce contentImprove reconstitution stabilityPharmaceutical non-active ingredientsMicrocapsulesSolubilityPurification methods

The invention discloses a purification method of a polyethylene glycol monomethyl ether-polylactic acid amphiphilic segmented copolymer for injection. The purification method comprises the following steps: dissolving polyethylene glycol monomethyl ether-polylactic acid amphiphilic segmented copolymer by water to prepare a water solution, making the water solution go through a strong acid cation exchange resin column to carry out chromatography, eluting the column by water, then filtering the eluent by a microporous filter membrane, sterilizing the eluent, freeze-drying the eluent so as to obtain purified polyethylene glycol monomethyl ether-polylactic acid amphiphilic segmented copolymer. The provided purification method can reduced the content of tin in polyethylene glycol monomethyl ether-polylactic acid amphiphilic segmented copolymer, and can improve the physical properties and solubility of the segmented copolymer. Moreover, the re-dissolution stability of a polymer micelle freeze-dried preparation, whose auxiliary material is the segmented copolymer, can be improved, the microbes can also be eliminated, and the microbes in the segmented copolymer will not exceed the standard.

Owner:XINAN PHARMA

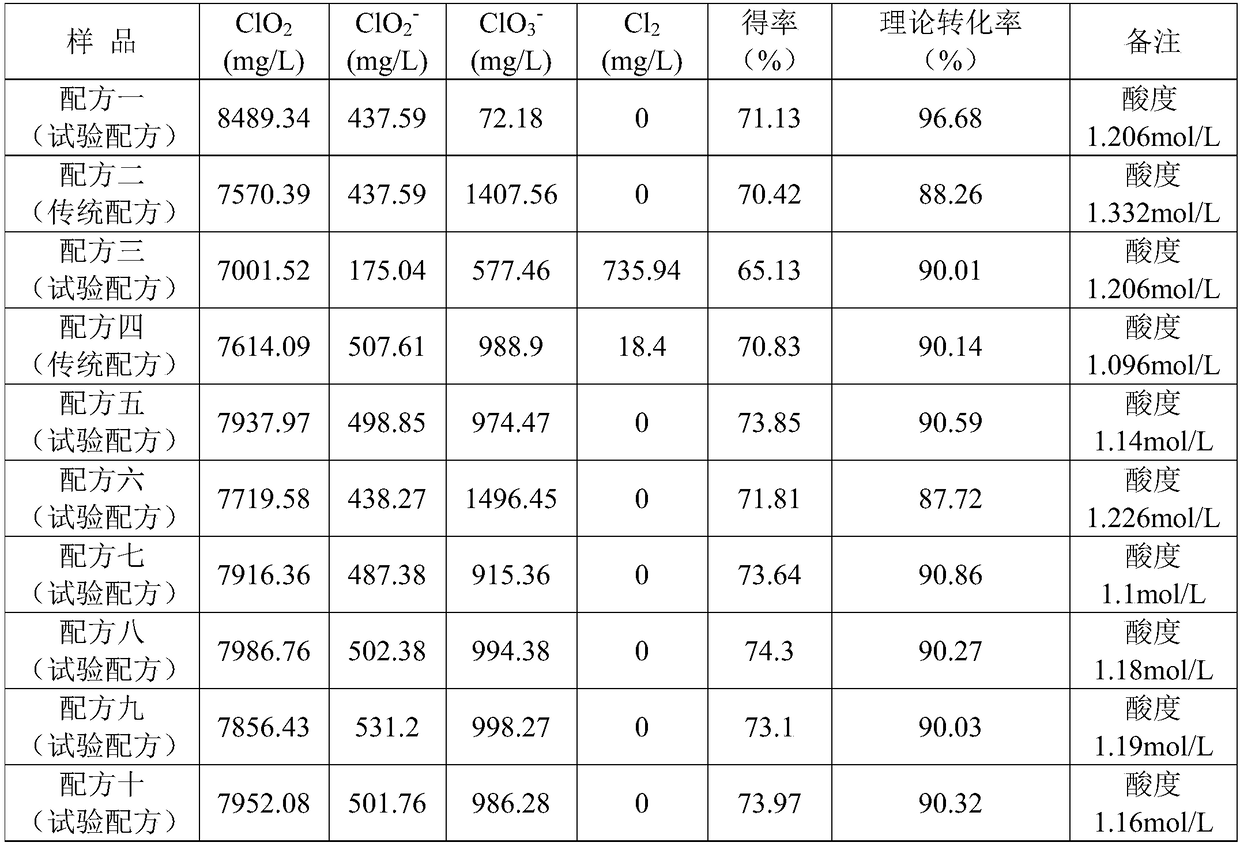

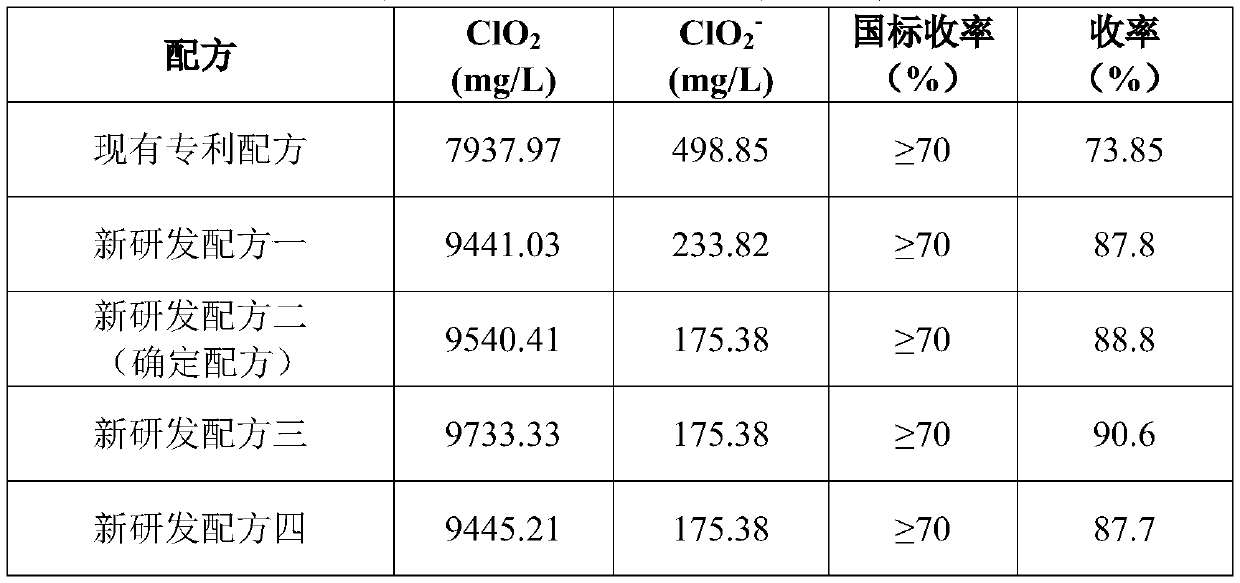

Method for preparing chlorine dioxide disinfectant

PendingCN108439342AImprove conversion rateMeet actual needsChlorine dioxideWater/sewage treatment by oxidationDisinfectantProduct gas

The invention discloses a method for preparing a chlorine dioxide disinfectant. The method comprises the following steps: preparing a sodium chlorite solution and a hydrochloric acid solution respectively; adding the two solutions into equipment and carrying out activation reaction; carrying out continuous aeration to generate high-purity and high-activity chlorine dioxide gas, wherein the purityof the gas is greater than or equal to 99 percent; conveying the chlorine dioxide gas to a drinking water application field. According to the method for preparing the chlorine dioxide disinfectant, disclosed by the invention, reasonable proportioning is carried out through a novel technological formula; the high-purity and high-activity chlorine dioxide gas can be prepared through activation operation.

Owner:四川蒙顶山化工有限公司

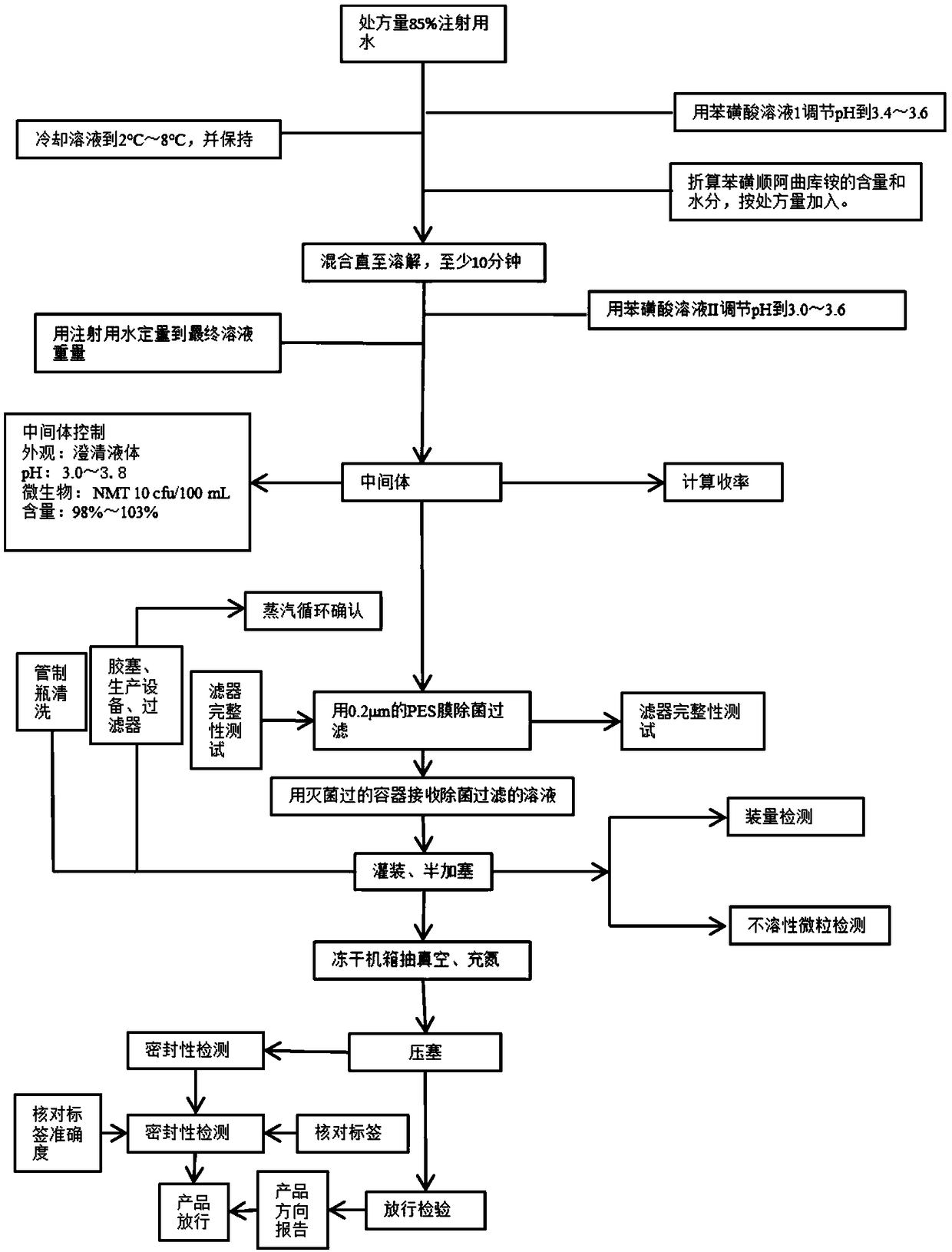

Preparation method of cisatracurium besilate injection without preservatives

InactiveCN109125259AMake sure not to exceedOrganic active ingredientsPharmaceutical delivery mechanismPreservative freeFiltration

The invention discloses a preparation method of cisatracurium besilate injection without preservatives. Each 1000ml of injection is prepared from the following components by weight proportion: 2 to 10g of cisatracurium besilate and proper amount of benzenesulfonic acid. The preparation method comprises the following steps: a, adding 85 percent of prescription volume of injection water into a preparation container, adjusting the pH by using a benzenesulfonic acid solution I, insulating, adding the cisatracurium besilate and stirring until the solution is clarified; b, adjusting the pH of the clarified solution obtained in the first step by using a benzenesulfonic acid solution II, determining the volume with injection water and finishing preparation; c, after the preparation of liquid medicine is finished, carrying out aseptic filtration and canning, feeding into a freeze-dying chassis, insulating, vacuumizing, charging nitrogen and carrying out compression tamponinging, thus obtaininga final product. According to the preparation method disclosed by the invention, the effect of the temperature on the product quality during the preparation process of the cisatracurium besilate injection is controlled as much as possible, so that impurities of the cisatracurium besilate injection do not exceed the standards within the validity period.

Owner:SHANGHAI PHARMA DONGYING JIANGSU PHARMA CO LTD

Special-purpose material for emulsion paint talcum powder

InactiveCN101033341AMake sure not to exceedReduce pollutionInorganic pigment treatmentEmulsion paintsHuman healthSolvent

This invention relates to a special material of latex paint talc powder, which is formed by the following components according to the percentage by weight: 26-29% of 325-2500 mesh talc, 1.5~2% film promoter agent, 0.5-0.7% of wetting dispersant, 0.2-0.4% of preservative, 0.2~0.4% of defoamer, 10-12% of color filler, 38-41% of styrene-acrylic emulsion, 18-20% of water. Talc is produced from talc ore with high brightness and low heavy metal, ensuring lead, chromium, cadmium and other heavy metals not surpassing the standard. Base material is not toxic, and agent has high boiling point without solvent and water dispersion additives, which meet the standard of environment-protective latex paint. Its curing process does not release toxic solvents, reducing pollution, conserving resource and energy, and benefiting human health and survival.

Owner:HAICHENG XINDA MINING

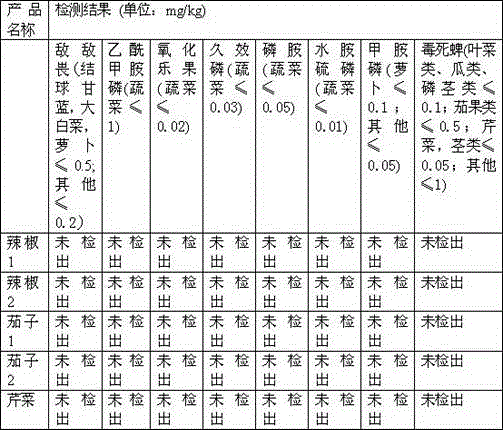

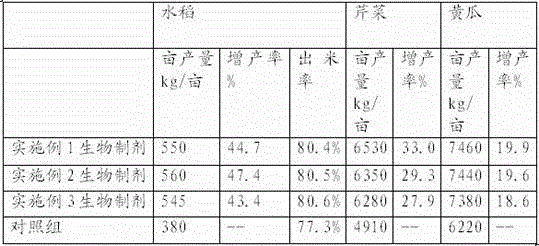

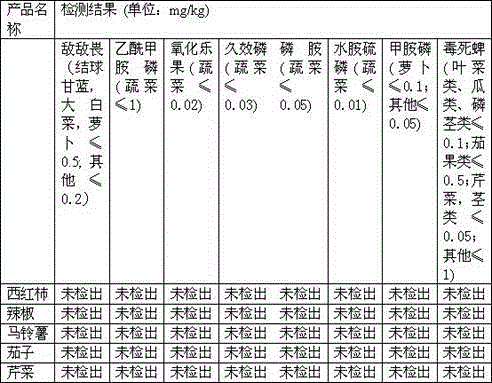

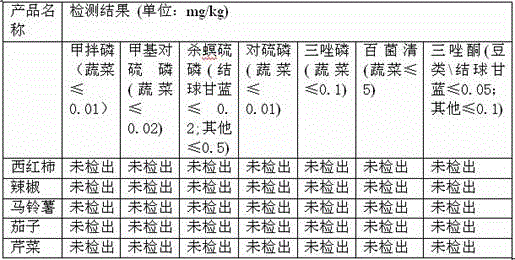

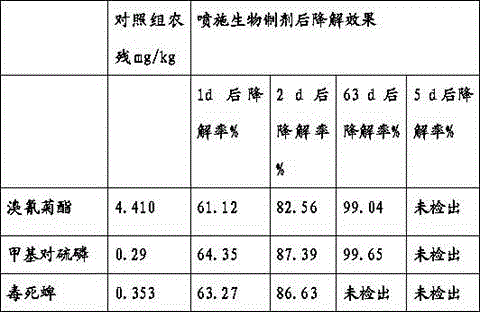

Biological agent capable of degrading pesticide residuals

InactiveCN105944280AEfficient degradationEnsure that pesticide residues do not exceed the standardPlant growth regulatorsBiocidePesticide residueBitter gourd

The invention discloses a biological agent capable of degrading pesticide residuals. The biological agent comprises apples, pomegranates, watermelons, tangerines, strawberries, grapefruits, carambolas, bananas, kiwi berries, hawhorns, mangos, longan, loquats, chufas, lemons, cucumbers, tomatoes, peppers, eggplants, carrots, celeries, broccoli, onions, burdocks, Chinese yams, bitter gourds, lotus roots, bigfoot mushrooms, agarics, filipendula, sanguisorba officinalis and Siberian saltbush fruit. The biological agent has the beneficial effects that the biological agent can degrade the pesticide residuals in crops, improves soil, and promote the crop yield increase and crop precocity; the quality and palatability of the crops are improved; the milled rice rate of paddy is increased; and the storage period of agricultural products is prolonged, soil and the water quality can be improved, and non-point source pollution is alleviated.

Owner:丁海伟

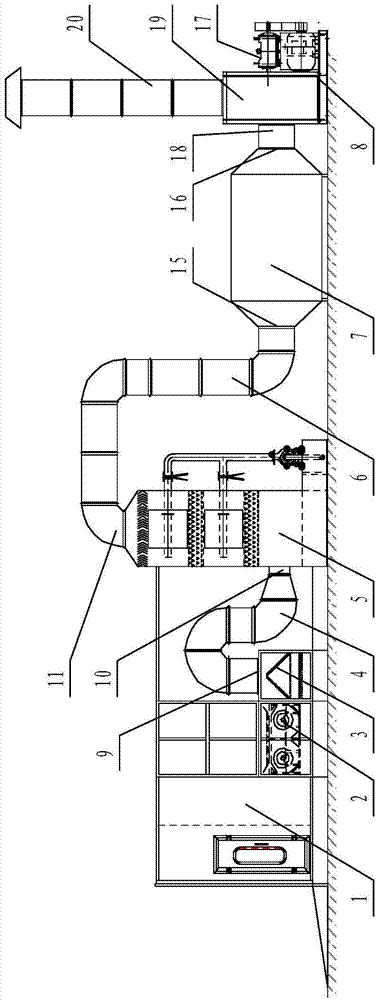

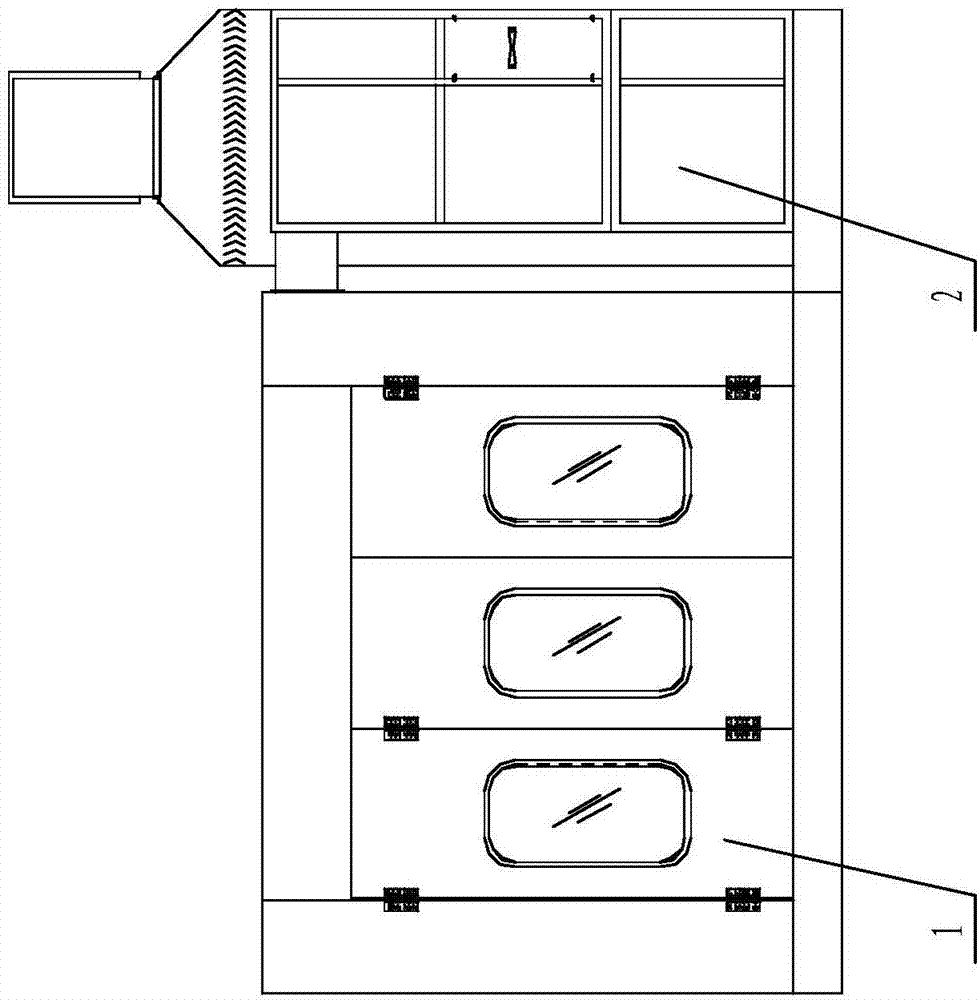

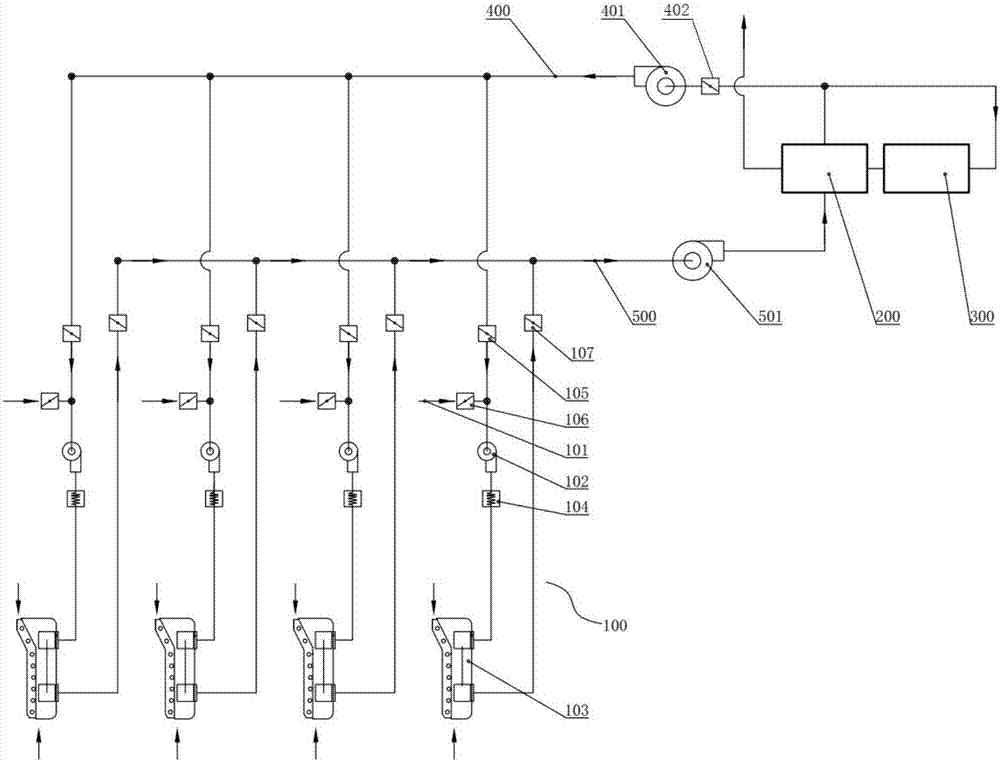

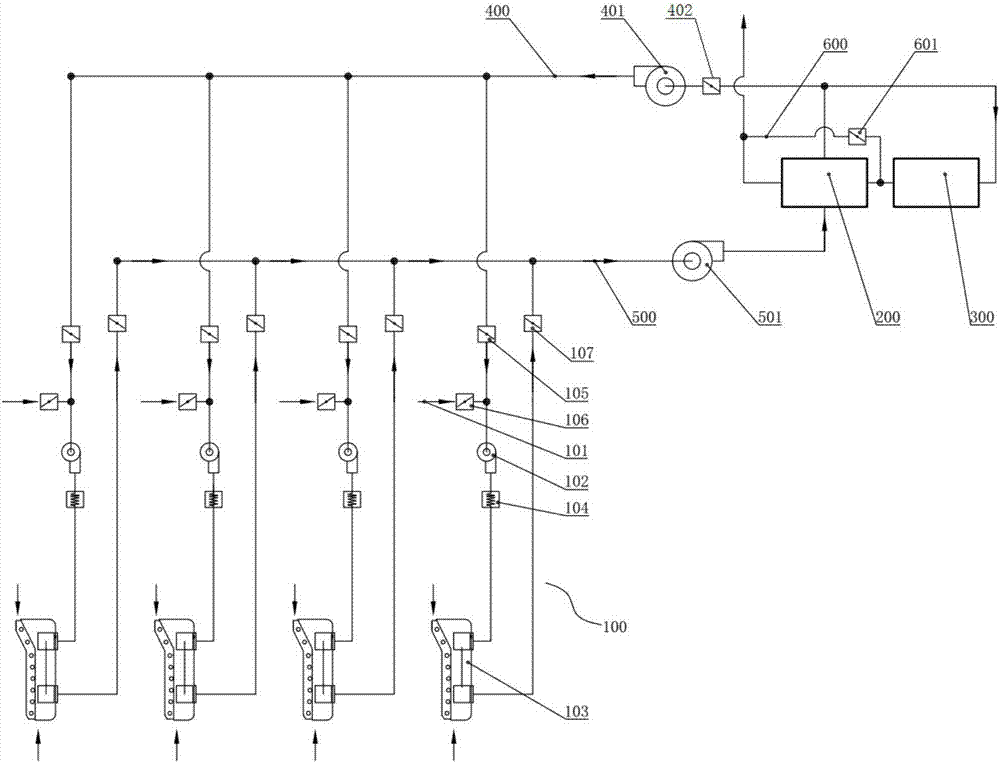

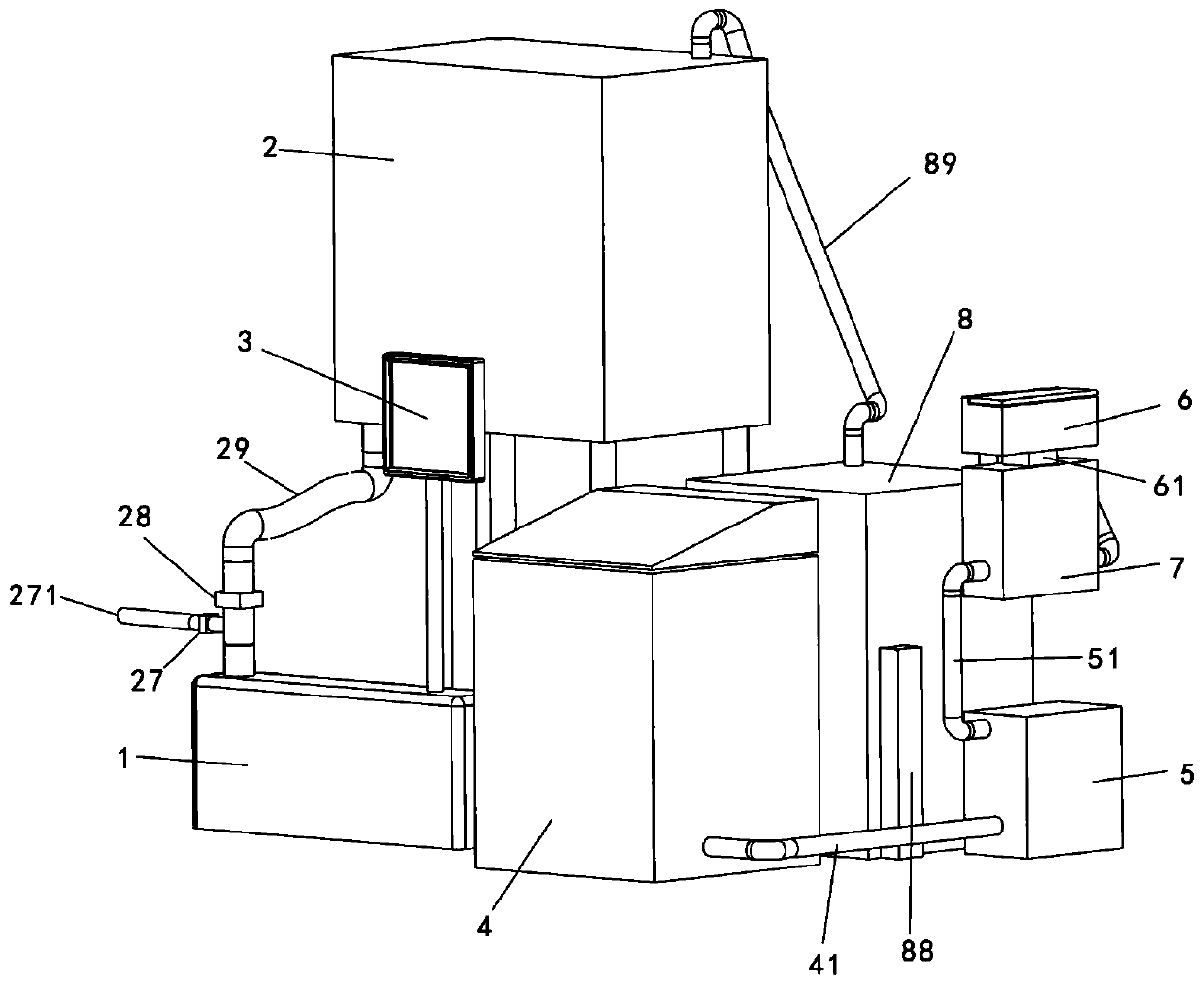

Novel environment-friendly waste gas treatment system for paint spraying and baking equipment

InactiveCN104841595AEfficient removalAdaptableCombination devicesSpraying apparatusParticulatesLacquer

The invention relates to a novel environment-friendly waste gas treatment system for paint spraying and baking equipment for paint spraying and drying operations of automobiles or other workpieces. The novel environment-friendly waste gas treatment system is characterized in that a platform air outlet of a paint spraying and baking booth is communicated with an air inlet of an air duct A, an outlet end of the air duct A is communicated with an air inlet of a paint mist separation device, an air outlet of the paint mist separation device is communicated with an air inlet of an odor purifying device through an air duct B, and an air outlet of the odor purifying device is communicated with an air inlet of an exhaust fan of an exhaust device. By combination of the paint mist separation device and the odor purifying device, volatile harmful substances and odorous gases generated in a paint spraying process can be eliminated effectively and thoroughly, solids in waste gas can be removed stably and thoroughly, pollution of the exhaust ducts and the exhaust fan is avoided, the problem of manual cleaning and maintenance is avoided as well, and particulate matters in the gas emitted to the atmosphere are guaranteed against limit exceeding to realize direct emission.

Owner:江苏景中景工业涂装设备有限公司

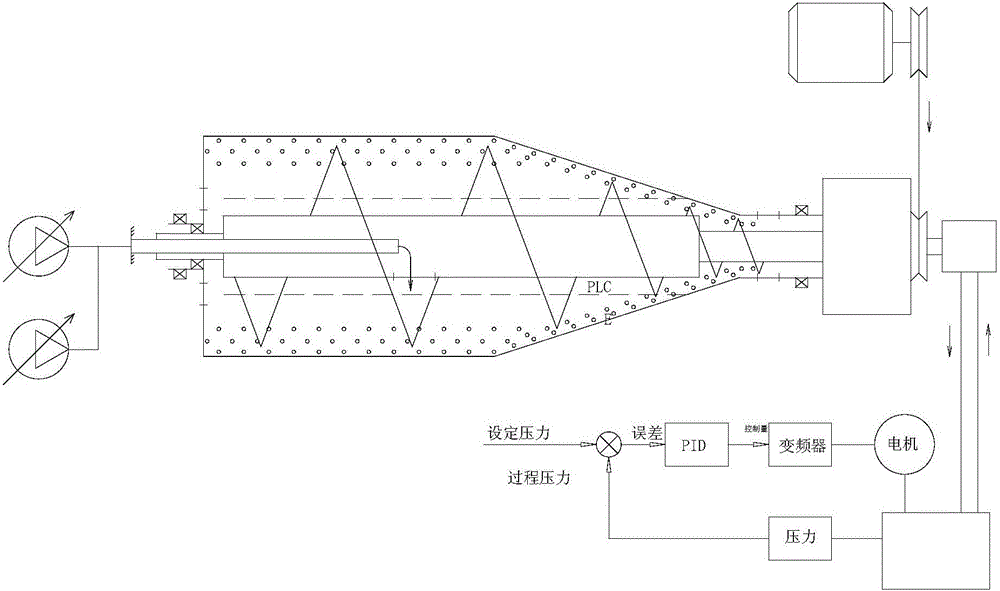

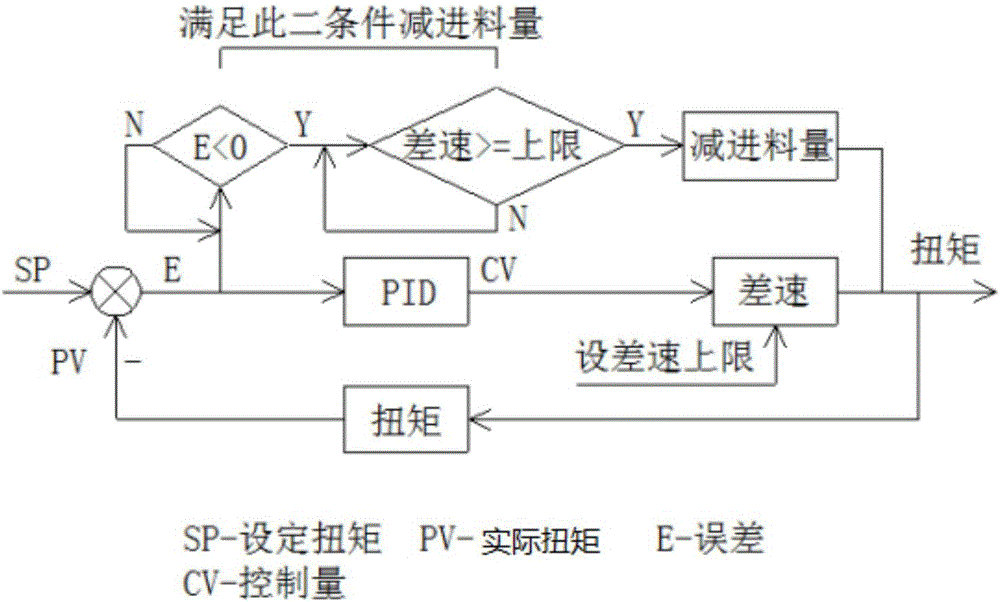

Constant Torque Control Method for Horizontal Screw Decanter

InactiveCN106334632AMake sure not to exceedTo achieve the purpose of constant torqueCentrifugesConstant torqueControl theory

A constant torque control method for horizontal screw decanter, combining differential adjustment and feed adjustment, achieves constant torque without exceeding any standard.

Owner:SHANGHAI CENTRIFUGE INST

Biological preparation capable of degrading pesticide residues

InactiveCN105875604AEfficient degradationEnsure that pesticide residues do not exceed the standardBiocideAgriculture tools and machinesWater ChestnutsBitter gourd

The invention discloses a biological preparation capable of degrading pesticide residues. The biological preparation is prepared from the following components: apples, pomegranates, watermelons, oranges, strawberries, shaddocks, star fruits, bananas, kiwi fruits, hawthorn fruits, cherries, water chestnuts, grapes, lemons, tomatoes, chilies, eggplants, wax gourds, carrots, celery, onions, burdocks, Chinese yams, bitter gourds, lotus roots, mushrooms, black fungi and semen juglandis. The biological preparation has the beneficial effects that the pesticide residues in crops can be degraded; soil is improved and the production increasing of the crops is promoted; early maturing of the crops is facilitated; the quality and palatability of the crops are improved; the rice yield of paddy rice is improved; the storage period of agricultural products is prolonged and the soil and water quality can be improved; non-point source pollution is improved.

Owner:YANTAI MINWANG ELECTROMECHANICAL TECH CO LTD

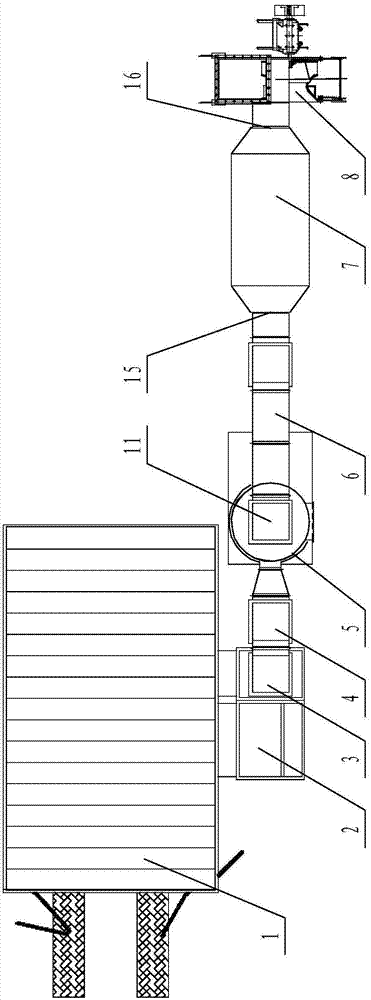

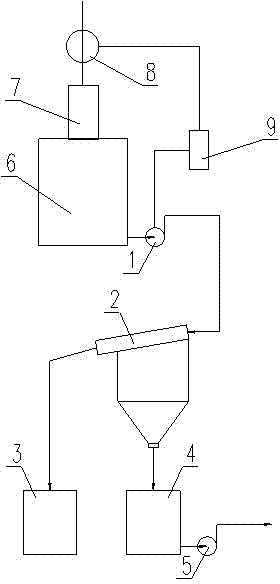

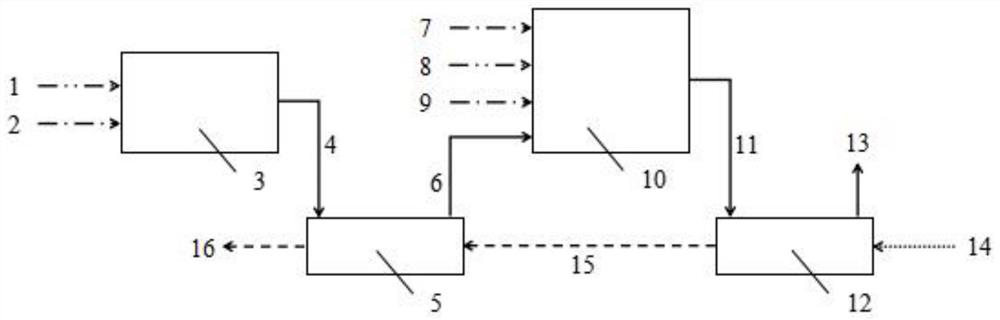

Hot air drying system increasing concentration and saving energy

ActiveCN107062879AEnsure that residues do not exceed the standardMake sure not to exceedDrying gas arrangementsDrying solid materialsProcess engineeringEnvironmental engineering

The invention discloses a hot air drying system increasing concentration and saving energy. The hot air drying system comprises a hot air drying unit, a heat exchanger and tail end treatment equipment. The hot air drying unit comprises an environment waste gas inlet pipe, a unit air supply fan and a drying box. An air inlet of the unit air supply fan communicates with the environment waste gas inlet pipe. An air outlet of the unit air supply fan communicates with an air inlet of the drying box. An air outlet of the drying box communicates with an air inlet of the low-temperature end of the heat exchanger. An air outlet of the low-temperature end of the heat exchanger communicates with the air inlet of the unit air supply fan and an air inlet of the tail end treatment equipment. An air outlet of the tail end treatment equipment communicates with an air inlet of the high-temperature end of the heat exchanger. An air outlet of the high-temperature end of the heat exchanger communicates with the outside atmosphere. Through the hot air drying system, energy can be saved effectively, the drying ability of drying equipment is improved, and invested cost and usage cost of the tail end treatment equipment are lowered.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

Method and device for discharging coarse granule slurry in decomposition production process of aluminum oxide

InactiveCN102531005AExtended operating cycleMake sure not to exceedAluminium oxides/hydroxidesSlagDecomposition

The invention discloses a method and a device for discharging coarse granule slurry in the decomposition production process of aluminum oxide. The method comprises the following steps of: assembling a coarse slurry discharge pump on each aluminum oxide decomposition groove; discharging coarse granule slurry at the bottom of the aluminum oxide decomposition groove by using the coarse slurry discharge pump; filtering the coarse granule slurry discharged by the coarse slurry discharge pump by using a coarse granule slurry discharge sieve; separating out coarse granule slag and fine granule slurry; conveying and returning the fine granule slurry by using the slurry pump to the aluminum oxide decomposition groove of a decomposition system; and exporting the coarse granule slag for sale or returning the coarse granule slag to the aluminum oxide production system, wherein the coarse granule slag serves as production raw materials. The device has the advantages of simple structure, high working efficiency, convenience and easiness in operation and capacity of improving product quality and also has the advantages of greatly reducing labor intensity of workers, contributing to environment friendliness, reducing production cost, saving raw materials, reducing energy consumption and the like.

Owner:GUIYANG AL-MG DESIGN & RES INST

Shipborne method for preparing organic fertilizer and coproducing antibacterial building material by utilizing sludge

InactiveCN111268876AIncrease contentMake sure not to exceedBio-organic fraction processingSolid waste disposalLand acquisitionBrick

The invention relates to a shipborne method for preparing an organic fertilizer and coproducing an antibacterial building material by using sludge. The method comprises the following steps: exploring,designing and sucking sludge, carrying out primary solid-liquid separation to lower the water content to 80% or below, stirring, carrying out air floatation to separate heavy metals, organic mattersand mud sand, sucking the organic matters from the upper layer of a separation tank, and carrying out fermentation compounding to obtain the organic fertilizer. The silt sediment is dehydrated for thesecond time to enable the water content to reach 20%-50%, the special cementing material is added according to 5%-30% of the silt dry basis, and the building block, the water permeable brick and thebuilding antibacterial building material with the antibacterial function can be obtained through stirring and forming. According to the technical method, land acquisition is not needed, secondary pollution is avoided, the method is environmentally friendly, the developed antibacterial veneer board is particularly suitable for public places of high-risk groups and sterile wards, food factories, pharmaceutical factories and high-end residences of the public places in a wide range, and good news is brought to health of people.

Owner:雷志刚 +1

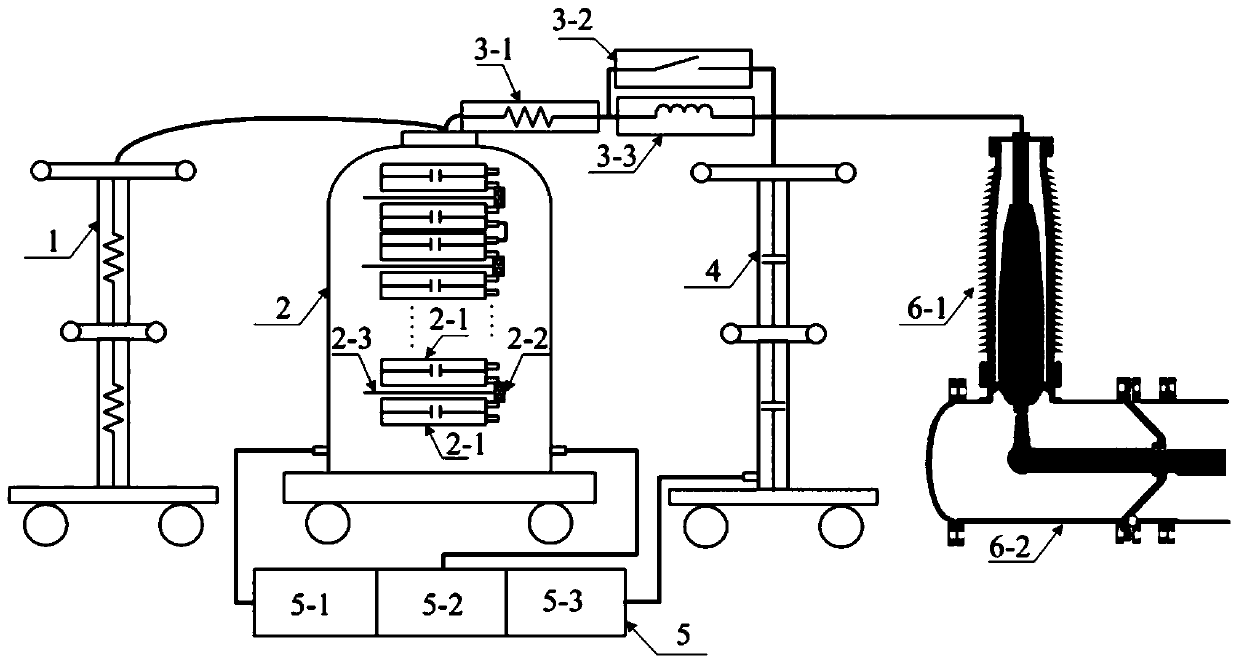

A lightning impulse and oscillating lightning impulse voltage test device on site in a substation

ActiveCN108008261BInteractive generationEasy to operateTesting dielectric strengthVoltage generatorLightning impulse voltage

The invention discloses a substation site lightning impulse and oscillation lightning impulse voltage test device which includes an impulse voltage generator, a wave front resistor, a wave front inductor, a wave tail resistor, a change-over switch and an impulse voltage measurement and control system. The high-voltage end of the impulse voltage generator is connected with one end of the wave tailresistor and one end of the wave front resistor. The other end of the wave tail resistor is grounded. The other end of the wave front resistor is connected with one end of the wave front inductor andone end of the change-over switch. The other end of the wave front inductor is connected with the other end of the change-over switch to form an output end. The impulse voltage measurement and controlsystem is used for controlling the charging and triggering of the impulse voltage generator. Both a lightning impulse voltage and an oscillation lightning impulse voltage can be generated. Interactive generation of a lightning impulse voltage and an oscillation lightning impulse voltage can be realized by switching the elements of the test circuit only. The operation is convenient, and the cost of equipment is low.

Owner:STATE GRID CORP OF CHINA +3

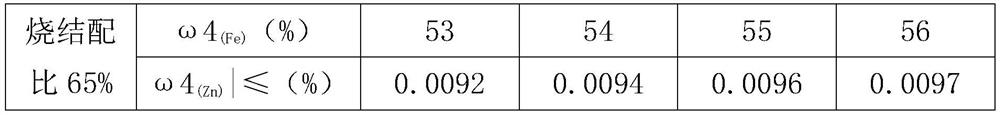

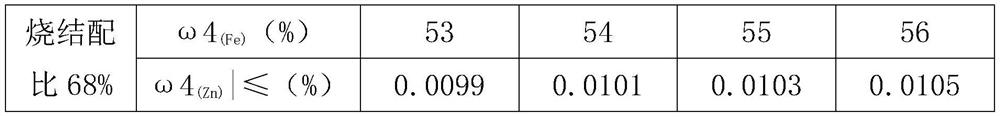

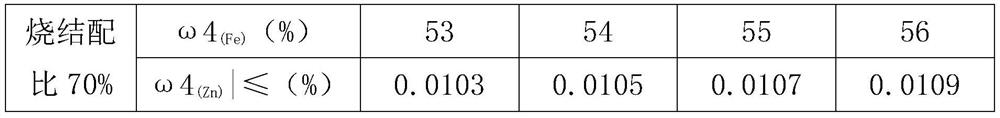

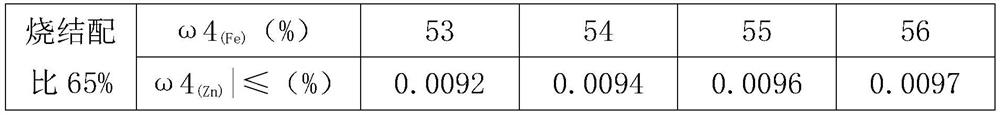

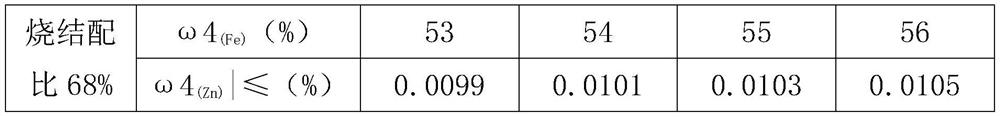

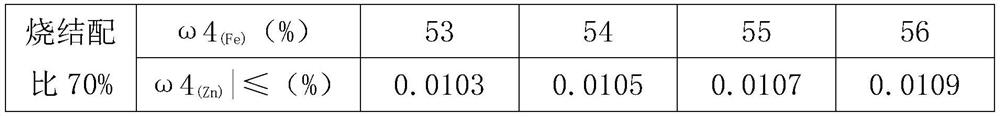

Method for controlling zinc load of blast furnace

ActiveCN113416808AEfficient use ofExtend your lifeBlast furnace detailsDesign optimisation/simulationZincMaterials science

The invention discloses a method for controlling the zinc load of a blast furnace. The method comprises the following steps that (1), the limit load Zn <(varies as)> of zinc entering the blast furnace is determined according to the level of crude fuel; (2), the furnace burden structure of the blast furnace is determined, and the zinc load Zn <(w)> in the natural lump ore in the furnace burden structure is calculated; (3), the blast furnace zinc load Zn <(R)> brought by the fuel is calculated according to the theoretical comprehensive fuel ratio; (4), the total zinc load Zn <(Z)> allowed to be brought into a sinter and a pellet is calculated according to the blast furnace burden structure; (5), the maximum value Zn <(S)> of the zinc load in the sinter or the maximum value Zn <(Q)> of the zinc load in the pellet is determined, and the zinc load range of another material is determined according to the furnace burden structure; (6), the zinc content of the sinter and the zinc content of the pellet under different proportions and grades are determined according to requirements; and (7), under the condition of ensuring that the furnace zinc load is in a reasonable range, production is carried out according to requirements. According to the method, long-period stable and smooth operation of the blast furnace and reduction of the ironmaking cost are effectively guaranteed, and the method not only ensures that the load of zinc entering the furnace does not exceed the standard, but also ensures the effective utilization of zinc-containing solid waste.

Owner:HEBEI XINDA IRON & STEEL GRP CO LTD

Preparation method of nitrate nitrogen denitrification catalyst

ActiveCN109317208ANo reduction in activityNo reduction in selectivityOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsHydrazine compoundPolystyrene

The invention provides a preparation method of a nitrate nitrogen denitrification catalyst and belongs to the field of sewage treatment. The preparation method is characterized by comprising the following preparation steps: activating and pre-treating a macroporous polystyrene resin carrier through a plurality of steps; carrying out one-step preparation of a compound catalyst; preparing a PdCl2 and Ce(NO3)3 primary impregnation solution; then carrying out ultrasonic treatment; after adding citric acid and tri-n-butyl citrate, adding copper acetate for dissolving; preparing an impregnation solution; impregnating the carrier in the impregnation solution and complexing; then impregnating into a mixed solution of sodium hydroxide and hydrazine hydrate to prepare the catalyst. According to thepreparation method, a common two-step preparation method is improved into a one-step preparation method; meanwhile, the activity and nitrogen gas selectivity of the catalyst are not reduced; a preparation technology is simple, scientific and reasonable. Metal ions are reduced to form a metal cluster and the metal cluster is deeply sunk into a three-dimensional network structure, so that the activity is uniformly distributed on the resin and the combination is firm.

Owner:CHINA PETROLEUM & CHEM CORP

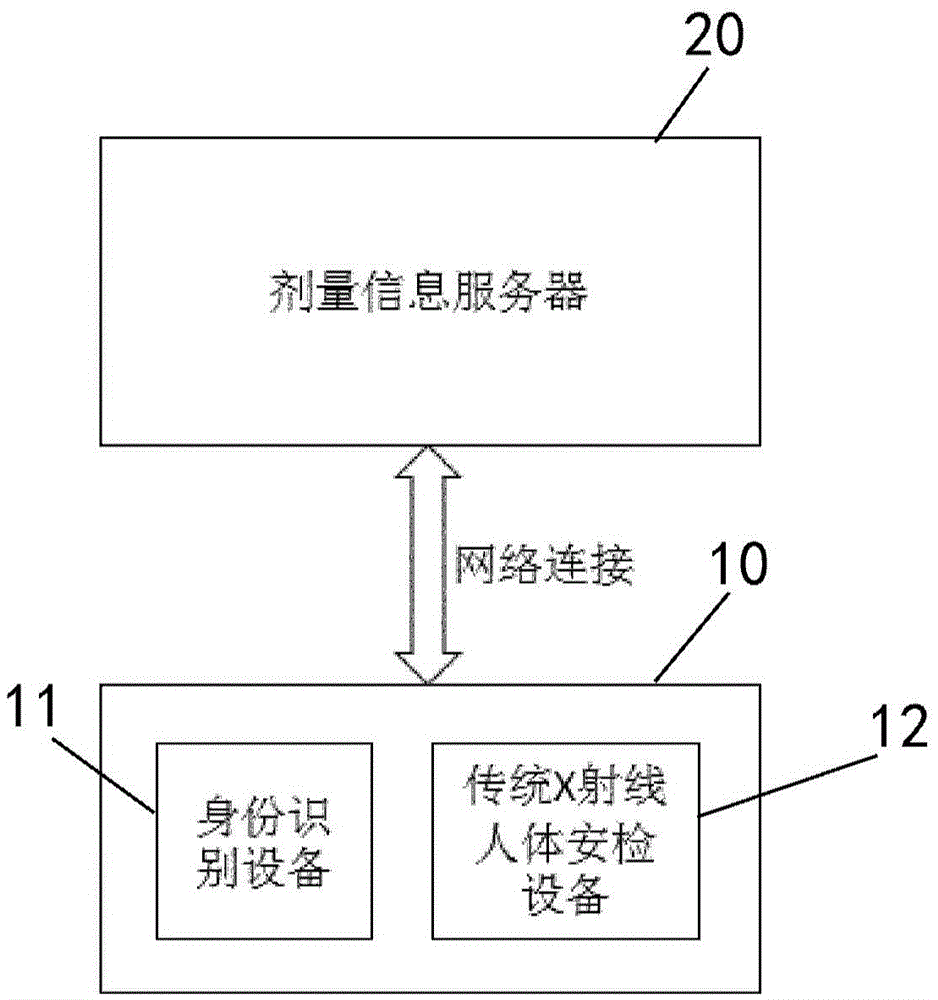

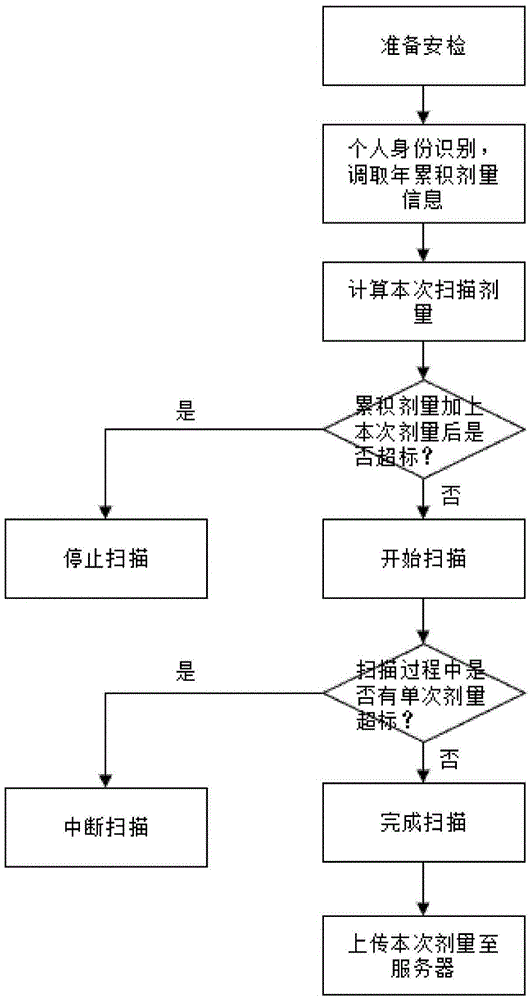

Ray-utilized human body security checking method and ray-utilized human body security checking system

InactiveCN105652331AMake sure not to exceedPrevent Radiation AccidentsNuclear radiation detectionHuman bodyRadiology

The invention relates to a ray-utilized human body security checking system and a ray-utilized human body security checking method. The ray-utilized human body security checking method comprises the steps of S1, performing personal identity identification on a checked person; S2, retrieving the accumulated ray scanning dose of a checked person according to an identity identification result; S3, acquiring the single-time ray scanning dose of ray-utilized human body security checking equipment, wherein the single-time ray scanning dose is the rated single-time scanning dose of the ray-utilized human body security checking equipment; S4, calculating the accumulated ray scanning dose of the checked person and the accumulated value of the single-time scanning dose of the ray-utilized human body security checking equipment; and S5, determining whether to perform the ray checking on the checked person according to whether the accumulated value exceeds a dose limit. The ray-utilized human body security checking system and the ray-utilized human body security checking method improve safety in performing ray checking on the human body.

Owner:NUCTECH CO LTD

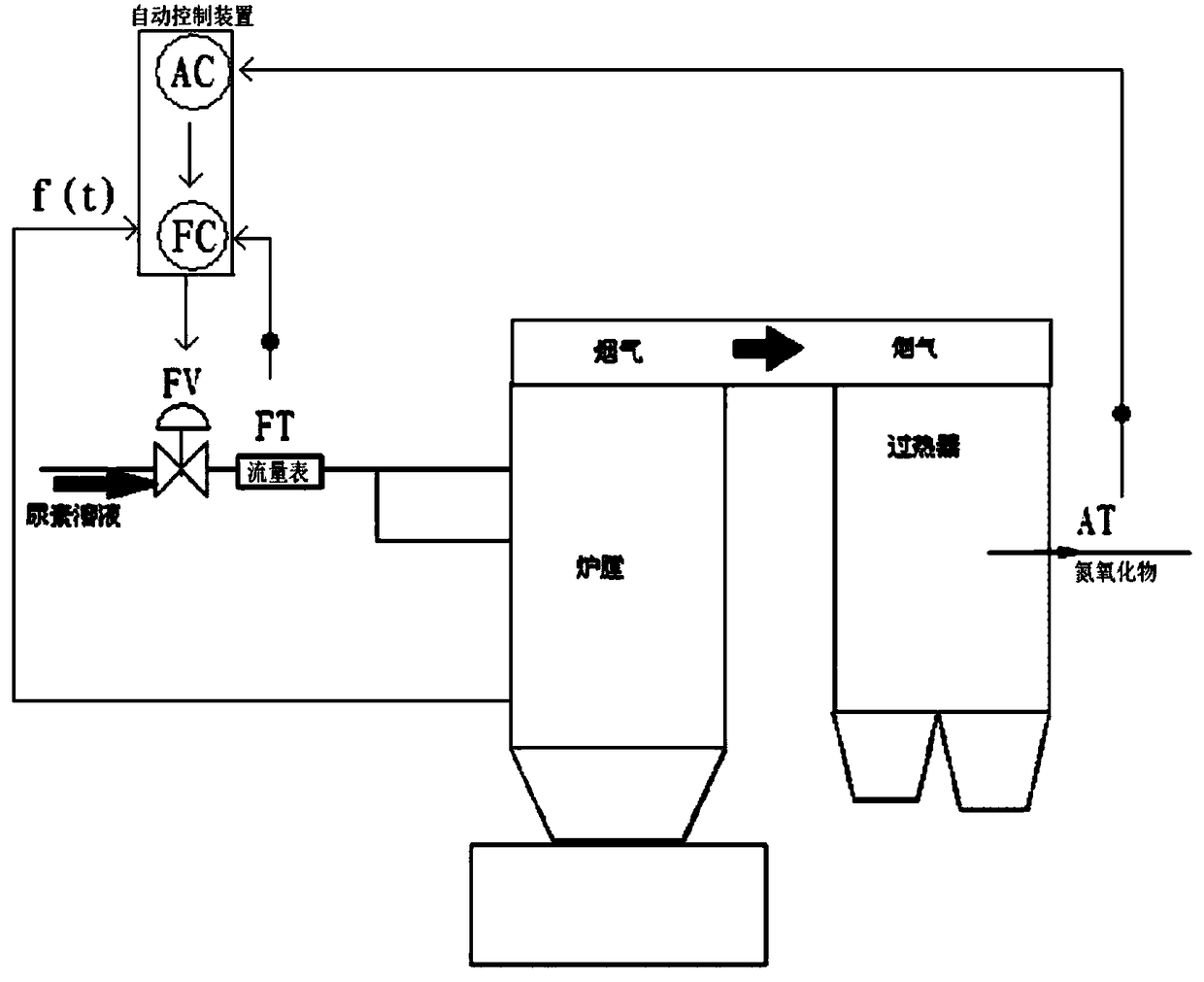

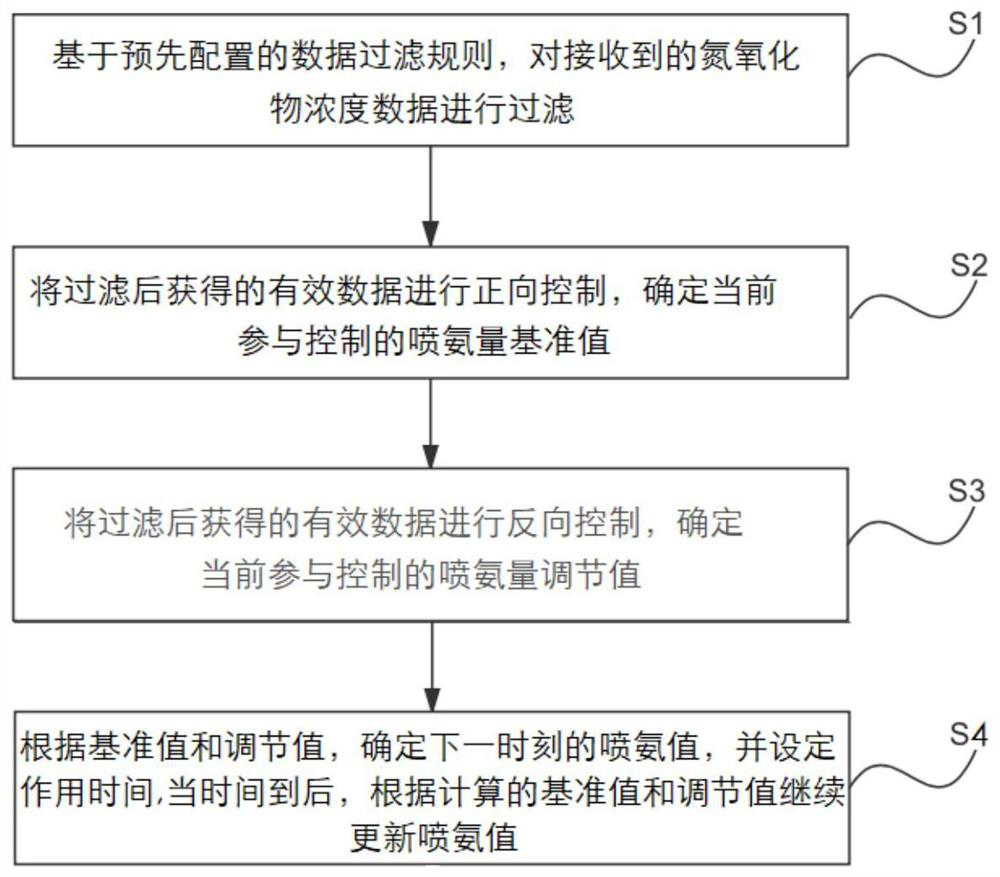

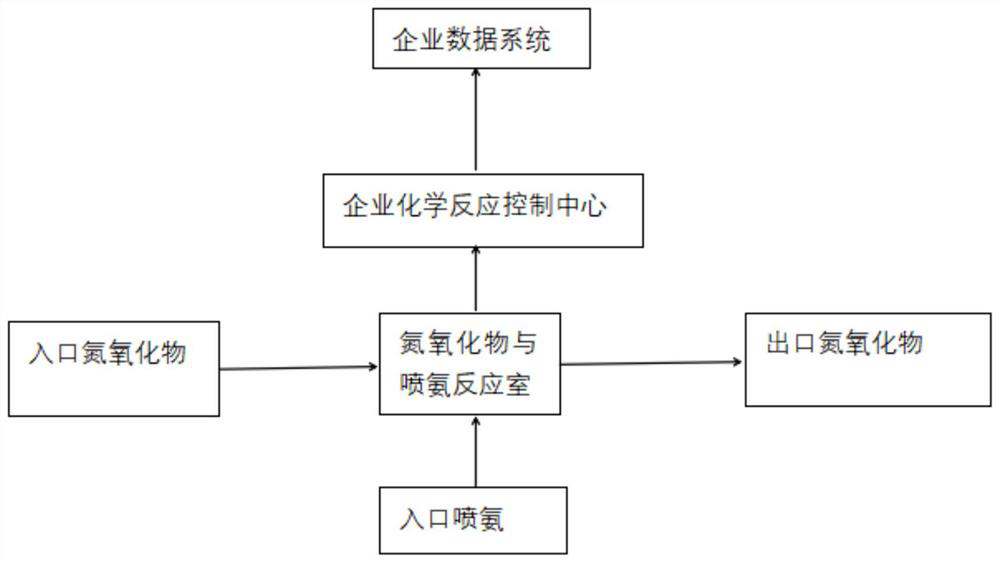

Method for automatically controlling nitrogen oxide concentration of denitrification system

PendingCN108919845AMake sure not to exceedReduce deliveryGas treatmentControlling ratio of multiple fluid flowsAutomatic controlUrea

The invention discloses a method for automatically controlling the nitrogen oxide concentration of a denitrification system. The method comprises the steps that S1, opening of an adjusting valve is adjusted, and after the concentration of nitrogen oxides in flue gas discharged out from a boiler keeps stable, the step S2 is executed; and S2, an automatic controls device is controlled to enter intothe automatic control mode, specifically, under the automatic control mode, the automatic control device controls the concentration of the nitrogen oxides in the flue gas discharged out from the boiler every the time interval delta T according to the following steps from S2.1 to S2.4. The concentration of the nitrogen oxides in the flue gas discharged out from the denitrification system is automatically controlled, it can be guaranteed that the concentration of the nitrogen oxides is stabilized to be near a nitrogen oxide target value SAT preset by an operator, it is guaranteed that ammoniacalnitrogen does not exceed the standard, and meanwhile the input quantity of a urea solution in the automatic control process is saved. A test shows that compared with a conventional method, fluctuation of the concentration of the nitrogen oxides at an outlet of the denitrification system adopting the method is stabilized from being larger than + / -100 mg / Nm<3> to being smaller than + / -15 mg / Nm<3>,and meanwhile the dosage of urea is saved by 50%.

Owner:CHINA PETROLEUM & CHEM CORP

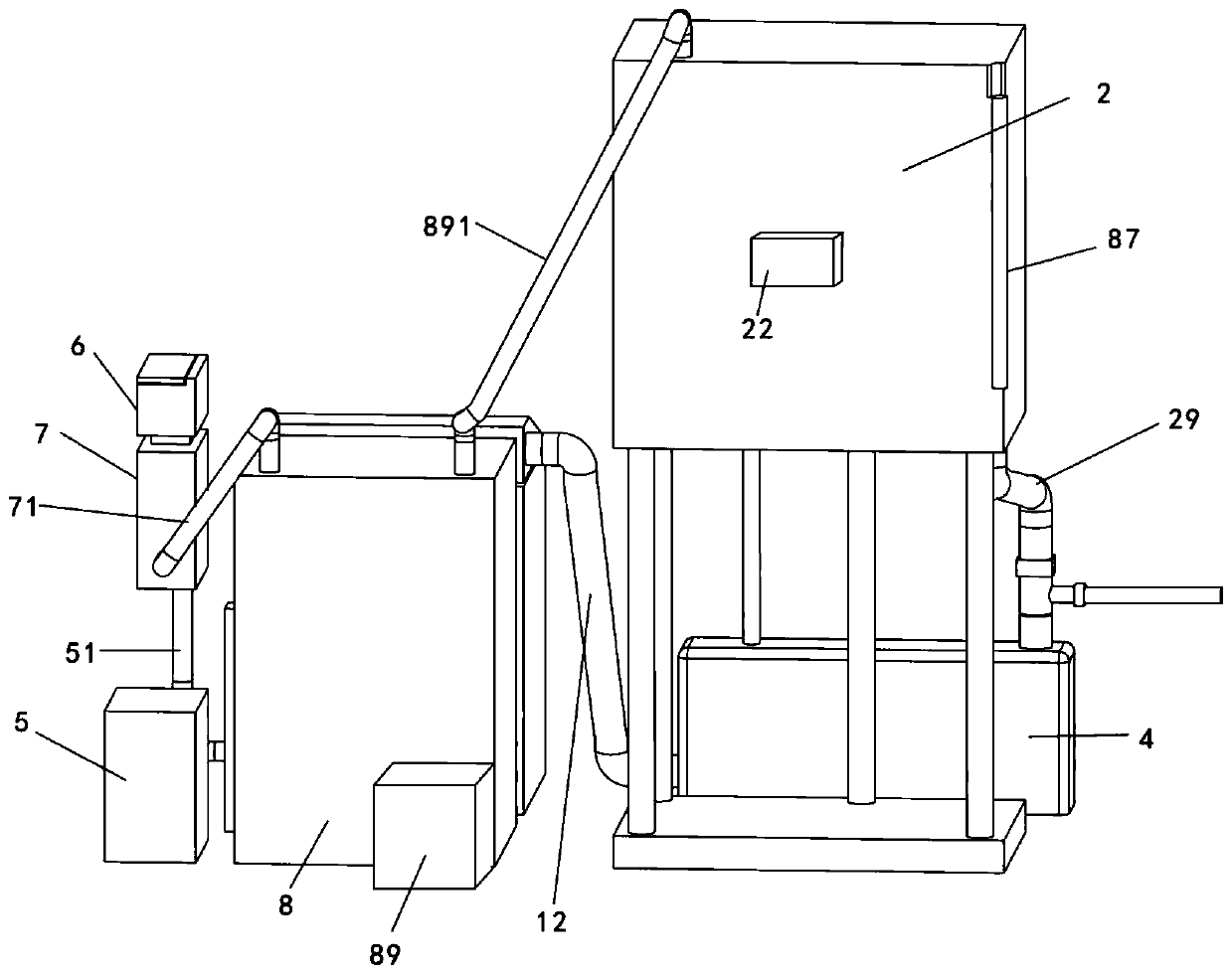

Industrial detergent-free washing zero emission method and device

PendingCN110407366AMake sure not to exceedRealize the goal of zero discharge of laundrySpecific water treatment objectivesTreatment involving filtrationMicrocontrollerWater source

The invention discloses an industrial detergent-free washing zero emission method and device. The device comprises a water treatment tank, a water tank, a water supply electromagnetic valve, a water supplement pipe, a water supplement electromagnetic valve, a washing machine, a first water pump, a coagulator, a filter and a control displayer, wherein the water tank is arranged above the water treatment tank, the water treatment tank is communicated with the water tank through a water supply pipe, the water supply electromagnetic valve controls the on / off state, the water supplement pipe is communicated with the water supply pipe, and the water supplement electromagnetic valve controls the on / off state of water supplement; the washing machine, the first water pump, the coagulator and the filter are arranged in sequence; a main single chip microcontroller and a second single chip microcontroller are connected with control circuits of various parts. The high-altitude water tank naturallysupplies water, the coagulator coagulates debris into clusters, the debris clusters are filtered away by an automatic cleaning filter screen, and compressed into solid wastes, and a silver ion detector and a water level detector ensure that heavy metal in water does not exceed the standard and water is supplemented timely. Through the measures, the aim of industrial detergent-free washing zero emission is achieved, washing water can be used repeatedly, and a clear water source is saved. The efficiency is high, the cost is low, and the washing effect is good.

Owner:广东康福星科技有限公司

Paper sludge transfer and storage silo

ActiveCN102963633BExtended service lifeSmooth rotationLarge containersLoading/unloadingPulp and paper industrySliding contact

The invention belongs to the technical field of a paper sludge incineration device, and particularly relates to a paper sludge transfer and storage silo, which comprises a sealed silo body, a screw feeder, a bottom axial-flow fan, a group of fire fighting nozzles, a material level meter, a double-end output drive device, a discharging chute, a belt feeding hopper, a belt conveyor and an accident ash-discharging pipe. The sealed silo body consists of a steel structural framework, a combined disc type bottom plate, a cylindrical silo wall and an umbrella-shaped silo roof, wherein the combined disc type bottom plate consists of a fixed disc, a rotary disc, a vertical rotating shaft and a base bracket, the fixed disc consists of a ring-shaped fixed plate, a central fixed plate and a ring-shaped power supply sliding contact line, and the rotary disc is provided with a sludge outlet, a ventilating manhole and a mounting hole. The sealed silo body is suitable for rotation and mixing of materials in the silo and the service life of the silo body is long. The screw feeder has the functions of revolution and rotation. Materials can be delivered into an appropriate position due to rotation while being mixed under effects of revolution, the problem of bypass of sludge materials can be avoided, and the efficiency of transfer and falling is high.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

A method for controlling zinc load in blast furnace

ActiveCN113416808BEfficient use ofExtend your lifeBlast furnace detailsDesign optimisation/simulationEngineeringZinc

The invention discloses a method for controlling the zinc load of a blast furnace. The method steps are: (1) determining the limit zinc load Zn of the blast furnace according to the level of raw fuel. (∝) ; (2) Determine the charge structure of the blast furnace, and calculate the zinc load Zn in the natural lump ore. (w) ; (3) Calculate the blast furnace zinc load Zn brought by the fuel from the theoretical comprehensive fuel ratio (R) ; (4) Calculate the total allowable zinc load Zn of sinter and pellets from the blast furnace charge structure (Z) ; (5) Determine the maximum zinc load Zn in the sinter (S) or the maximum zinc load Zn in pellets (Q) ; Determine the zinc load range of another material according to the structure of the charge; (6) Determine the zinc content of sinter and pellets with different ratios and grades according to requirements; (7) In the case of ensuring that the zinc load into the furnace is within a reasonable range production as required. The method effectively ensures the long-term stable running of the blast furnace and the reduction of iron-making costs; it not only ensures that the zinc load into the furnace does not exceed the standard, but also ensures the effective utilization of zinc-containing solid waste.

Owner:HEBEI XINDA IRON & STEEL GRP CO LTD

Two-stage combustion coupled two-stage heat exchange process and system for desulfurization waste liquid

PendingCN114001363AIncrease temperatureImprove qualitySteam generation using pressureIndirect carbon-dioxide mitigationCombustorFlue gas

The invention relates to the technical field of combustion boilers, in particular to a two-stage combustion coupled two-stage heat exchange process and system for desulfurization waste liquid. The system comprises a first combustor used for combustion of crude sulfur, a second combustor used for combustion of sulfur-containing waste liquid, a first heat exchange device and a second heat exchange device, wherein stage-I flue gas generated in the first combustor enters the second combustor after passing through the second heat exchange device, stage-II flue gas generated in the second combustor is used for preparing acid after passing through the first heat exchange device; and cooling water sequentially flows through the first heat exchange device and the second heat exchange device, and high-quality steam is generated after the cooling water exchanges heat with the stage-II flue gas in the first heat exchange device and the stage-I flue gas in the second heat exchange device. After two-stage combustion is coupled with two-stage heat exchange, the steam quality is improved, then the power generation efficiency is improved, NOx in flue gas does not exceed the standard, meanwhile, the content of NH3 in the flue gas is reduced, and interference of NH3 on the subsequent acid making process is weakened.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Purification method of polyethylene glycol monomethyl ether-polylactic acid amphiphilic block copolymer for injection

ActiveCN105315444BReduce contentImprove reconstitution stabilityPharmaceutical non-active ingredientsMicrocapsulesMicroorganismPolymer science

The invention discloses a method for purifying a polyethylene glycol monomethyl ether-polylactic acid amphiphilic block copolymer for injection, which comprises dissolving the polyethylene glycol monomethyl ether-polylactic acid amphiphilic block copolymer in water Prepare an aqueous solution, and the obtained aqueous solution is used for strong acid cation exchange resin column chromatography, eluted with water, and the obtained eluate is sterilized by filtration with a microporous membrane, and freeze-dried to obtain purified polyethylene glycol monomethyl ether-poly Lactic acid amphiphilic block copolymer; the purification method can reduce the tin content of poly(ethylene glycol monomethyl ether-polylactic acid amphiphilic block copolymer); improve its physical properties and improve solubility; The reconstitution stability of the prepared polymer micelle freeze-dried preparation; it can also remove microorganisms to ensure that the microorganisms do not exceed the standard.

Owner:XINAN PHARMA

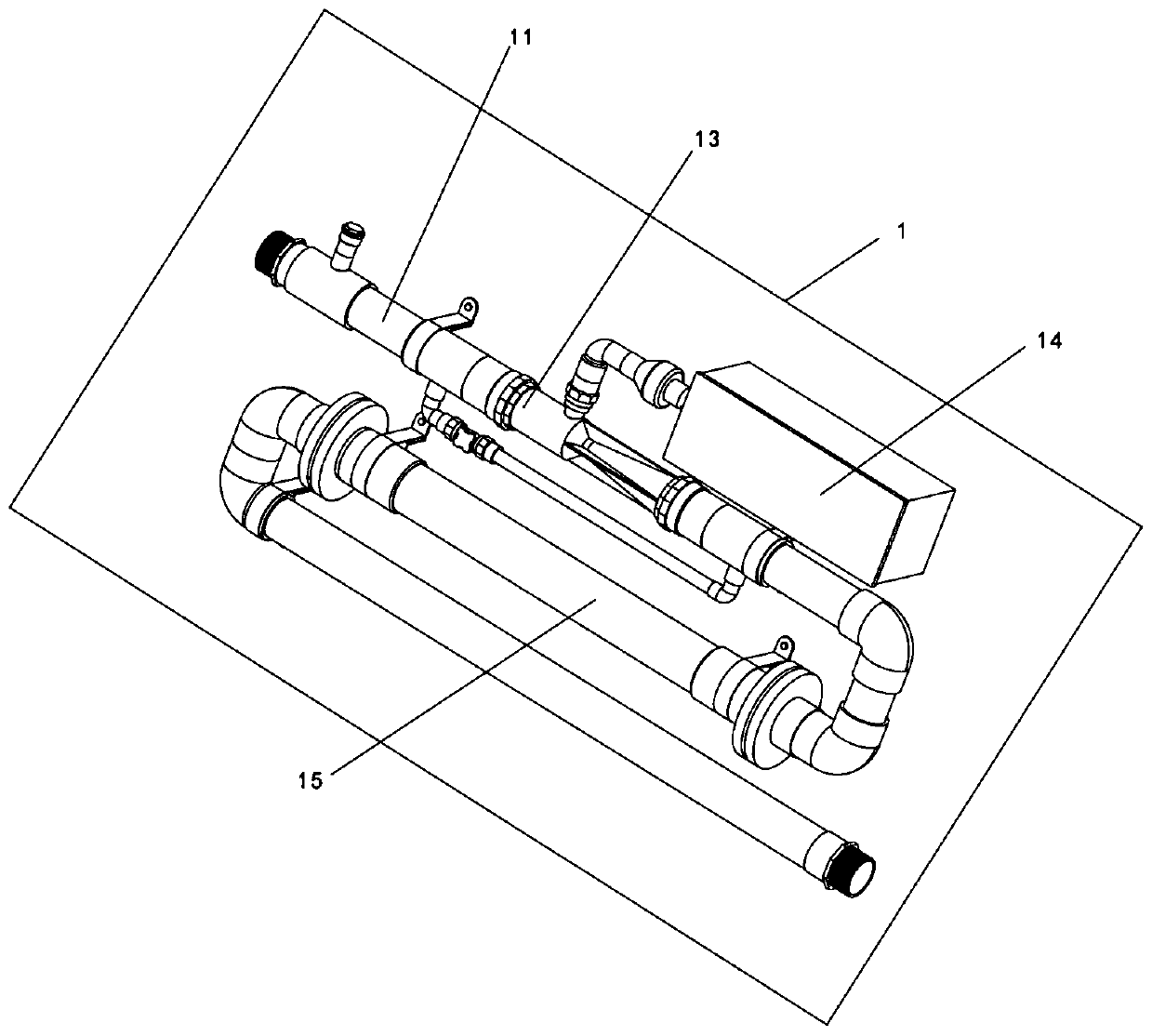

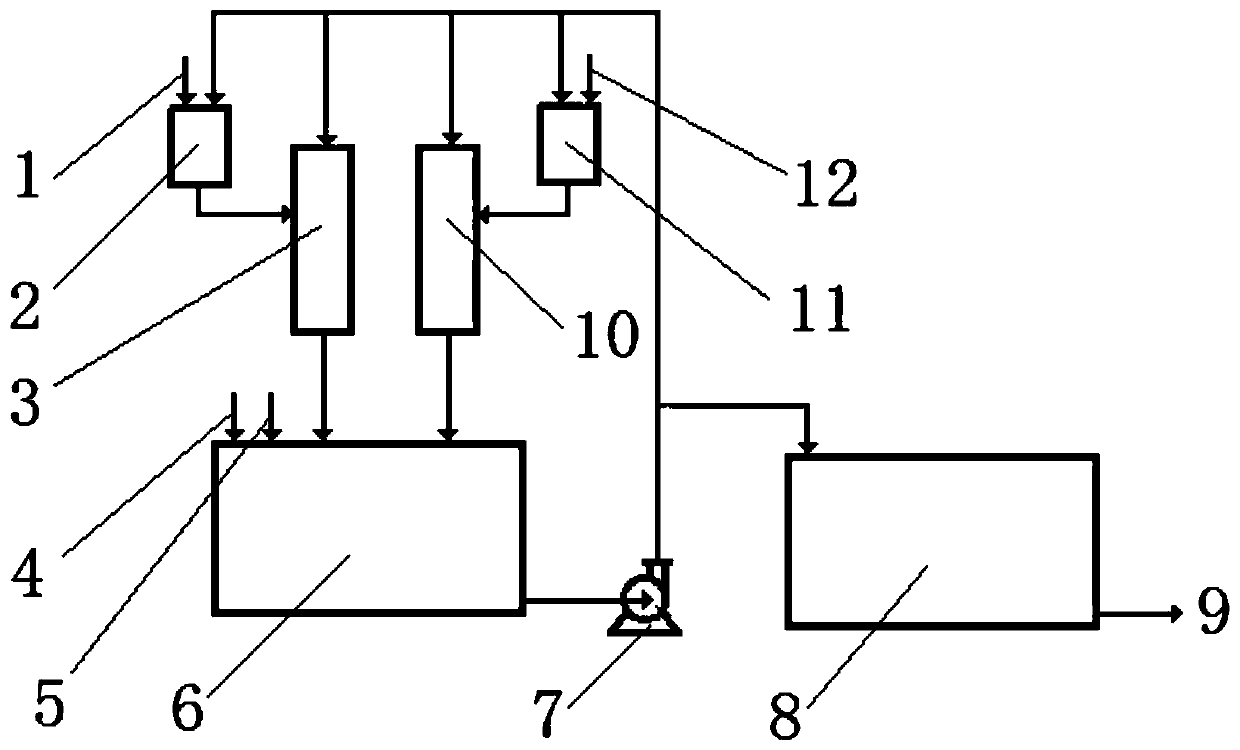

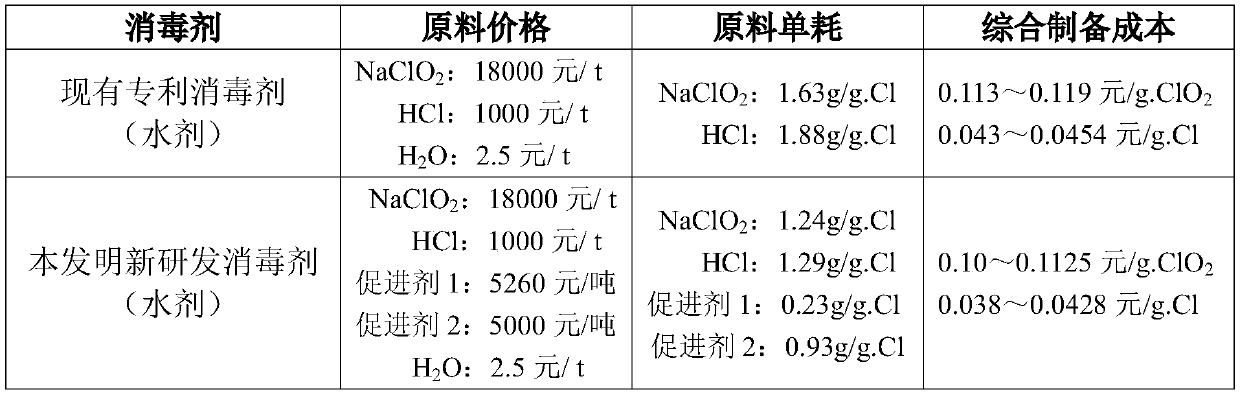

Method for preparing liquid chlorine dioxide disinfectant and device thereof

ActiveCN111017880AWell mixedHigh yieldChlorine dioxideAgainst vector-borne diseasesOXALIC ACID DIHYDRATEChlorous acid

The invention relates to a method for preparing a liquid chlorine dioxide disinfectant, which comprises the following steps: respectively preparing an agent A and an agent B, adding the agent A and the agent B into adding equipment for activation reaction, and continuously aerating to generate high-purity and high-activity chlorine dioxide gas which is sent to a drinking water application place through the adding equipment; wherein the agent A is a sodium chlorite solution, the agent B is a hydrochloric acid mixed solution and comprises a hydrochloric acid solution, an accelerant I and an accelerant II, the accelerant I is citric acid, and the accelerant II is oxalic acid. According to the method for preparing the liquid chlorine dioxide disinfectant, a new process formula of the agent B solution is utilized, reasonable proportioning is conducted, then the agent B solution is reasonably proportioned with the original agent A solution, and through activation operation, high-yield and high-purity chlorine dioxide gas can be prepared.

Owner:四川蒙顶山化工有限公司

Method and device for discharging coarse granule slurry in decomposition production process of aluminum oxide

InactiveCN102531005BExtended operating cycleMake sure not to exceedAluminium oxides/hydroxidesPrillSlag

The invention discloses a method and a device for discharging coarse granule slurry in the decomposition production process of aluminum oxide. The method comprises the following steps of: assembling a coarse slurry discharge pump on each aluminum oxide decomposition groove; discharging coarse granule slurry at the bottom of the aluminum oxide decomposition groove by using the coarse slurry discharge pump; filtering the coarse granule slurry discharged by the coarse slurry discharge pump by using a coarse granule slurry discharge sieve; separating out coarse granule slag and fine granule slurry; conveying and returning the fine granule slurry by using the slurry pump to the aluminum oxide decomposition groove of a decomposition system; and exporting the coarse granule slag for sale or returning the coarse granule slag to the aluminum oxide production system, wherein the coarse granule slag serves as production raw materials. The device has the advantages of simple structure, high working efficiency, convenience and easiness in operation and capacity of improving product quality and also has the advantages of greatly reducing labor intensity of workers, contributing to environment friendliness, reducing production cost, saving raw materials, reducing energy consumption and the like.

Owner:GUIYANG AL-MG DESIGN & RES INST

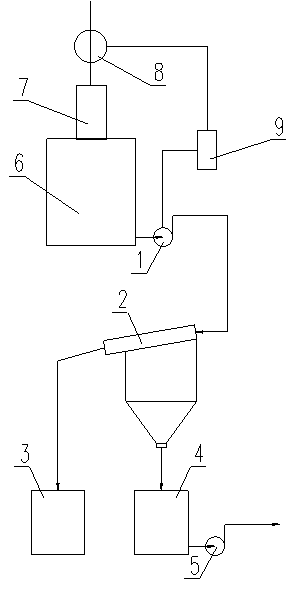

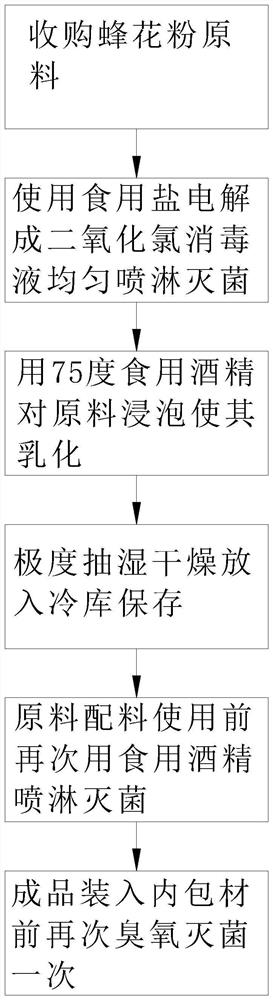

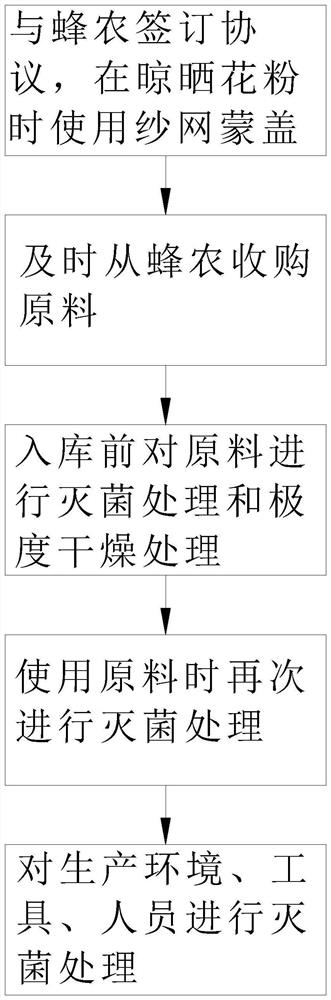

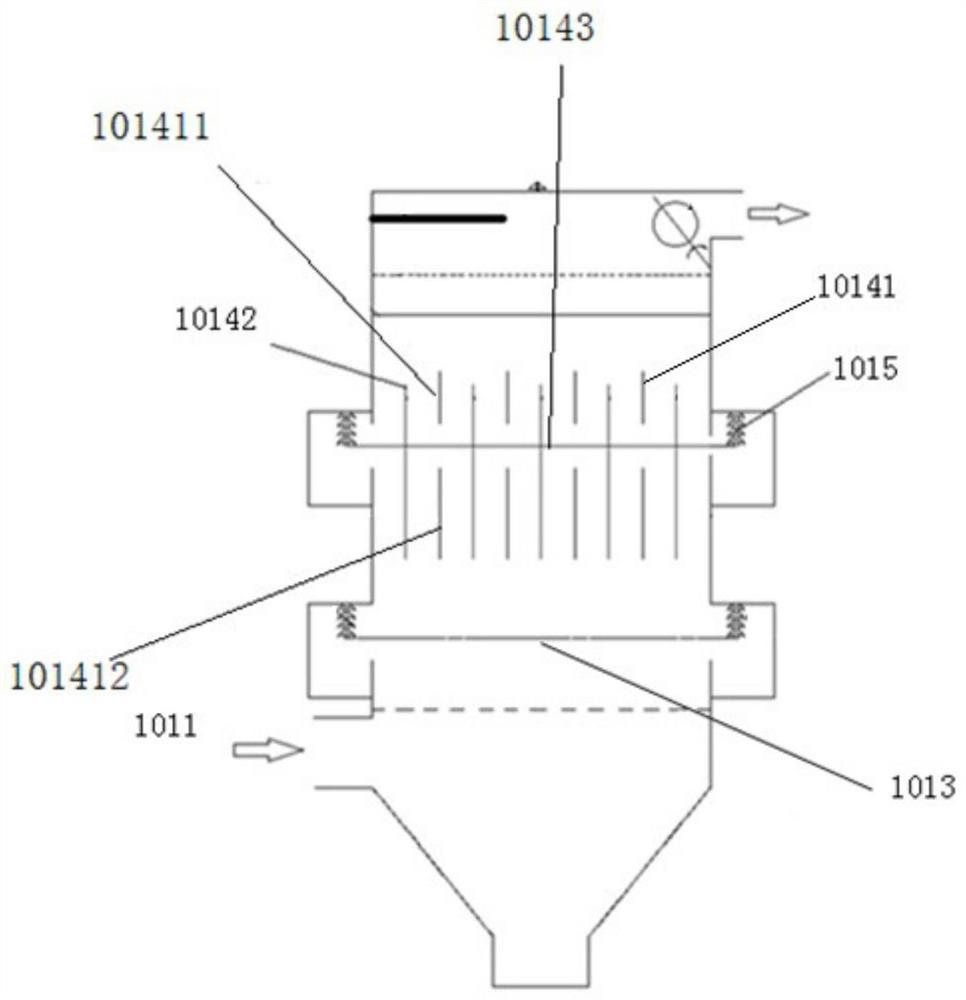

Novel technological method for producing bee pollen tablets at constant temperature of 37 DEG C

PendingCN114732117AEnsure that the colonies do not exceed the standardMake sure not to exceedFood preservationFood ingredientsBiotechnologyChlorine dioxide

The invention relates to the field of production technologies of bee pollen products, in particular to a novel technological method for producing bee pollen tablets at the constant temperature of 37 DEG C. S1, purchasing raw materials; s2, after the raw materials enter a factory, electrolyzing the raw materials into chlorine dioxide disinfectant by using edible salt, and uniformly spraying the chlorine dioxide disinfectant to sterilize the raw materials; s3, after ten minutes, soaking the raw materials with 75-degree edible alcohol to emulsify the raw materials, taking out the raw materials after 72 hours, and granulating; s4, carrying out extreme dehumidification and drying, carrying out sterilization once by using ozone in the dehumidification and drying process, and then putting into a sealed container refrigeration house for storage; s5, the edible alcohol is sprayed again for sterilization before the raw material ingredients are used; and S6, carrying out ozone sterilization again before the finished product is loaded into the inner packing material. On the premise that bacterial colonies of bee pollen products do not exceed the standard, it is guaranteed that active and functional components in the pollen are not lost, and the products which are high in activity, high in quality, good in effect and competitive are produced; and radiation raw materials are prevented from being used, so that the use safety of the product is ensured.

Owner:张卫

Clean room system for semiconductor manufacturing and multistage electric field dust removal method thereof

PendingCN113522525ATake up a lot of spaceIncrease construction costsExternal electric electrostatic seperatorElectric supply techniquesThermodynamicsDust control

The invention provides a clean room system for semiconductor manufacturing and a multi-stage electric field dust removal method thereof. The clean room system comprises a clean room and a multi-stage electric field dust removal system; the multi-stage electric field dust removal system comprises at least two electric field devices connected in series and further comprises a power supply, and an electric field anode and an electric field cathode of each electric field device are electrically connected with two electrodes of the power supply device respectively; the voltage value of the power supply of the electric field device is enough to ensure that the total dust removal efficiency (100%-(100%-P1%) * (100%-P2%) *...... * (100%-Pn%) of the electric field dust removal system is greater than a preset value, the ozone output quantity is smaller than a preset value, P1%, P2%...... Pn% are the dust removal efficiency of the first-stage electric field device, the dust removal efficiency of the second-stage electric field device,..., the dust removal efficiency of the n-th-stage electric field device respectively in sequence, and n is an integer greater than 1.

Owner:SHANGHAI BIXIUFU ENTERPRISE MANAGEMENT CO LTD

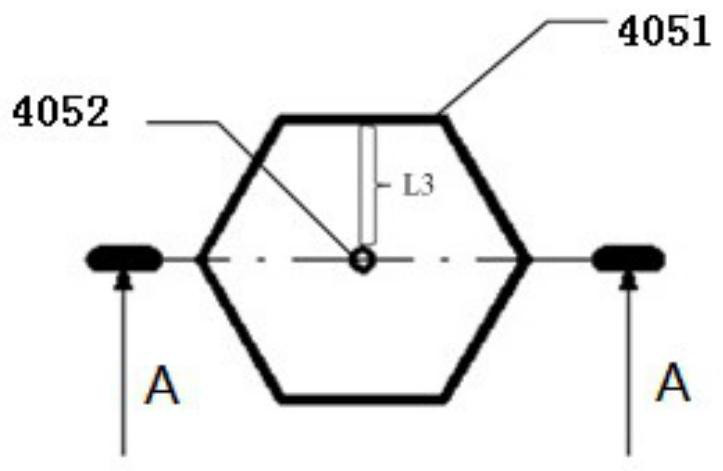

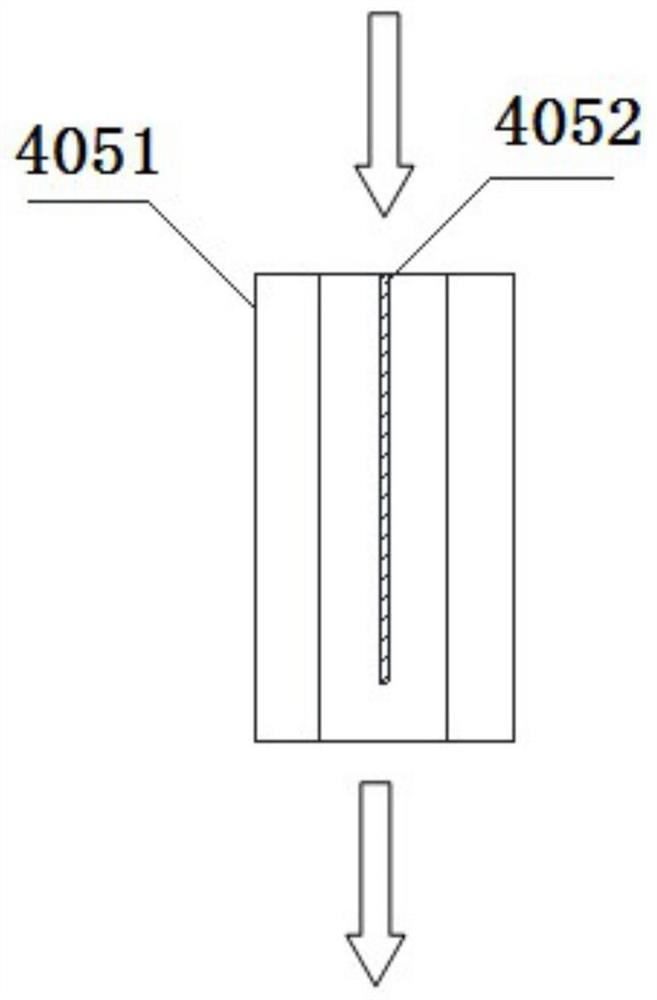

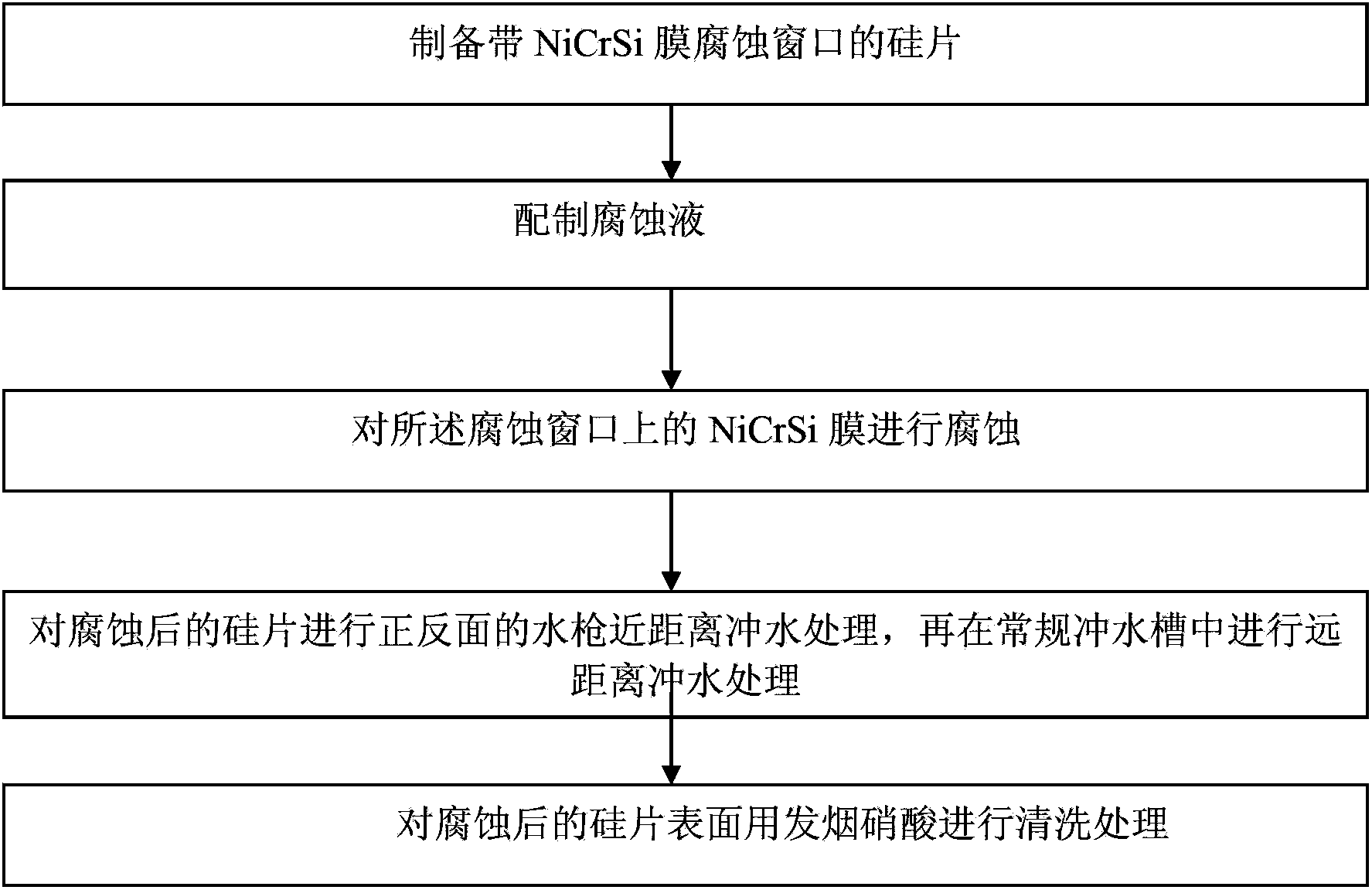

Method for etching NiCrSi film through wet process

ActiveCN102664148BGood removal effectConducive to cost controlSemiconductor/solid-state device manufacturingEtchingShortest distance

The invention relates to a method for etching a NiCrSi film through a wet process. Since a step of washing the two surfaces of a silicon wafer at a short distance by separately using a water gun, the problem that cerium sulfate on the surface of the silicon wafer is difficult to remove by adopting the existing conventional etching method is effectively solved. Since the product cerium sulfate which is obtained after the NiCrSi film is etched through the wet process is insoluble in water, the method is not suitable for etching multiple silicon wafers which can be etched at one time by adopting the conventional etching method and the method is only suitable for etching the silicon wafers one by one, the cost control of raw materials of the method is superior to the cost control of the raw materials of the conventional etching method. By using fixed supports and culture dishes, the problem that the conventional method is inconvenient to operate is effectively solved; and by using clamping apparatuses which are separately used for placing the silicon wafers and are respectively provided with a lifting handle, the problem of excessive etching of the conventional etching method is effectively solved. After the NiCrSi film is etched by adopting the method, the point defects caused by the cerium sulfate on the surface of the silicon wafer are smaller than 20 per field of view and the qualified rate of the processed surfaces after microscopic examination can reach more than 90%.

Owner:NO 24 RES INST OF CETC

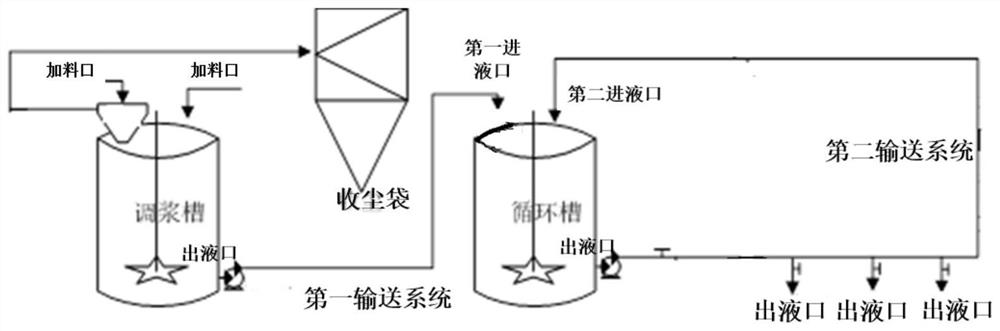

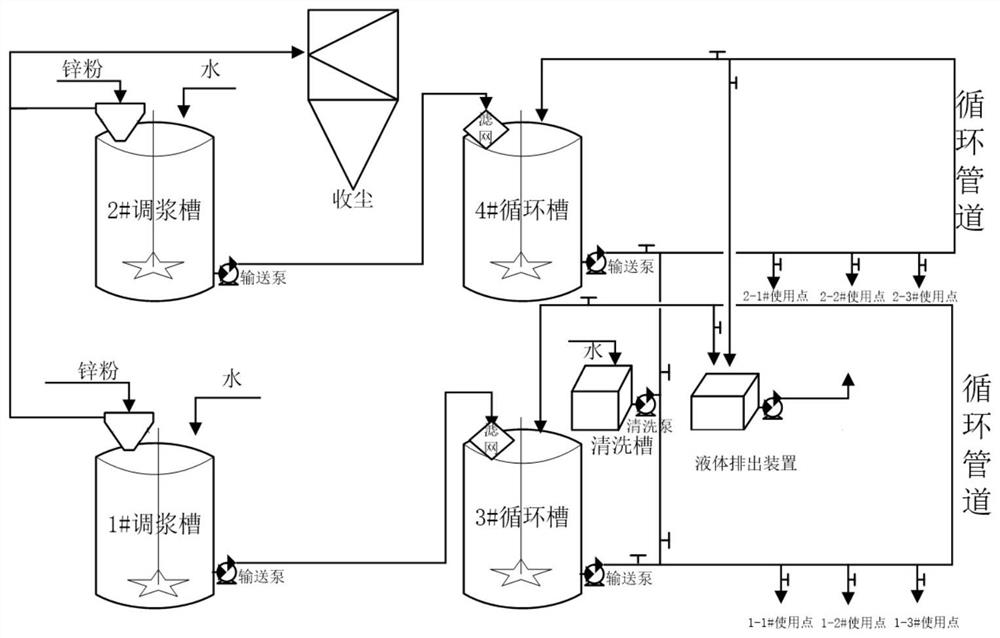

Device and method for wet addition of zinc powder

ActiveCN113462893AMake sure not to exceedSolve pollutionMixing methodsMixer accessoriesPhysical chemistryHydrometallurgy

The invention discloses a device and method for wet addition of zinc powder. The device for wet addition of the zinc powder comprises a slurry mixing tank and a circulating tank. The upper part of the slurry mixing tank is provided with a dust collecting bag and at least one feeding hole, and the lower part of the slurry mixing tank is provided with a liquid outlet; the upper part of the circulating tank is provided with a first liquid inlet and a second liquid inlet, the lower part of the circulating tank is provided with a liquid outlet, the first liquid inlet of the circulating tank is connected with the liquid outlet of the slurry mixing tank through a first conveying system, and the liquid outlet of the circulating tank is connected with the second liquid inlet of the circulating tank through a second conveying system; and at least one liquid outlet is formed in the second conveying system, and the at least one liquid outlet in the second conveying system is connected with a purification reaction tank for zinc hydrometallurgy. Zinc powder and water are added into the slurry mixing tank for centralized slurry mixing, then conveyed to the circulating tank and then conveyed to the purification reaction tank for zinc hydrometallurgy for use, so that zinc powder wet adding is achieved, and the problems that in the zinc powder dry adding process, zinc powder flies and is lost, and environmental pollution is caused are solved.

Owner:云南云铜锌业股份有限公司

Optimized self-control method and system for industrial enterprise emission pollution

PendingCN113813754AMake sure not to exceedSave human effortDispersed particle separationNitrogen oxidesAutomatic control

The invention discloses an optimized self-control method and a system for industrial enterprise emission pollution, and the method comprises the steps: filtering received nitrogen oxide concentration data at an inlet based on a pre-configured data filtering rule, carrying out the forward control of effective data obtained after filtering, and determining a reference value which participates in the control of the ammonia spraying amount at present; based on a pre-configured data filtering rule, filtering the received nitrogen oxide concentration data at the outlet, performing reverse control on effective data obtained after filtering, and determining an adjustment value currently participating in control of the ammonia spraying amount; and determining the ammonia spraying value at the next moment according to the reference value of the ammonia spraying amount and the adjusting value given by an anti-control system. According to the scheme, the ammonia spraying amount is automatically controlled and adjusted from the data level, it is guaranteed that nitric oxide at an outlet does not exceed a set value, and meanwhile a large amount of manpower and material resources are saved.

Owner:北京云岚科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com