Method and device for discharging coarse granule slurry in decomposition production process of aluminum oxide

A production process, alumina technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of reduced production capacity, failure to meet production needs, and increased production costs, so as to prevent overload operation, improve product quality, and factory production capacity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

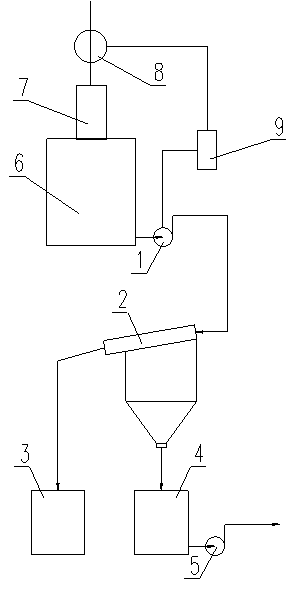

[0016] Embodiment of the present invention: a schematic diagram of the structure of a device for discharging coarse particle slurry during the production process of alumina decomposition of the present invention is as follows figure 1 As shown, the device includes the existing alumina decomposition tank 6. During manufacture, the upper row coarse slurry pump 1 is installed on each alumina decomposition tank 6, and the feed port of the row coarse slurry pump 1 is set At the bottom of the alumina decomposition tank 6, the outlet end of the coarse slurry pump 1 is connected to the upper row of coarse screen 2 through a pipeline, and the row of coarse screen 2 can adopt an existing screen with a sieve diameter less than or equal to 150 μm Finished product; Then a coarse particle slag collection box 3 is set at the coarse material discharge port of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com