Two-stage combustion coupled two-stage heat exchange process and system for desulfurization waste liquid

A technology for desulfurization waste liquid and heat exchange system, applied in the field of combustion boilers, can solve the problems of restricting steam quality, interfering with the acid-making process, restricting power generation efficiency, etc., achieving high economic benefits, simple system structure, and reducing the yield of generated acid. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

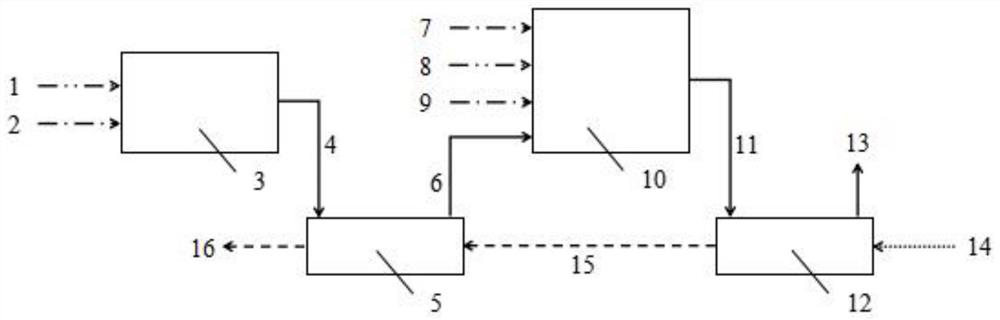

[0035] Coarse sulfur is atomized and sprayed into the first burner 3 in liquid form, and oxygen-enriched air with 30% oxygen content is simultaneously passed into the first burner 3, and the atomized liquid crude sulfur is combusted to produce stage I flue gas with a temperature higher than 1300°C ; The flue gas in the first stage enters the second heat exchange device 5 to cool down, where the temperature of the flue gas in the first stage drops below 1000 ° C, and then enters the second burner 10; the desulfurization waste liquid with a salt content of w.50% is atomized and sprayed into the second burner 10, and the supplementary combustion gas and supplementary air are synchronously fed into the second burner 10. By adjusting the volume of supplementary combustion gas and supplementary air, the temperature of the flue gas in the second stage is controlled at 900-1200°C, and the second burner The second-stage flue gas from 10 enters the first heat exchange device 12, where th...

Embodiment 2

[0037] Coarse sulfur is atomized and sprayed into the first burner 3 in liquid form, and oxygen-enriched air with 50% oxygen content is simultaneously passed into the first burner 3, and the atomized liquid crude sulfur is combusted to produce stage I flue gas with a temperature higher than 1500°C ; The flue gas in the first stage enters the second heat exchange device 5 to cool down, where the temperature of the flue gas in the first stage drops below 1000 ° C, and then enters the second burner 10; the desulfurization waste liquid with a salt content of w.75% is atomized and sprayed into the second burner 10, and the supplementary combustion gas and supplementary air are synchronously fed into the second burner 10. By adjusting the volume of supplementary combustion gas and supplementary air, the temperature of the flue gas in the second stage is controlled at 900-1200°C, and the second burner The second-stage flue gas from 10 enters the first heat exchange device 12, where th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com