Novel technological method for producing bee pollen tablets at constant temperature of 37 DEG C

The technology of bee pollen tablet and process technology is applied in the new technology field of bee pollen tablet production at a constant temperature of 37 degrees, which can solve problems such as affecting the efficacy of bee pollen products and destroying active ingredients of bee pollen, and achieves high-quality, competitive, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

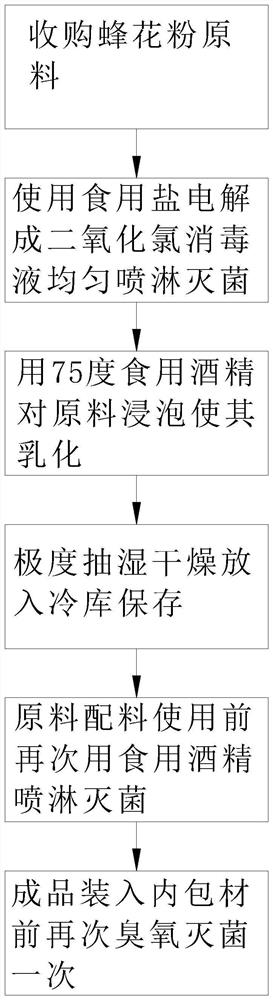

[0025] like figure 1 As shown, a novel process technology method for the production of bee pollen tablets at a constant temperature of 37 degrees proposed by the present invention comprises the following steps;

[0026] S1. Purchase bee pollen raw materials;

[0027] S2. After the raw material of bee pollen enters the factory, use edible salt to electrolyze it into chlorine dioxide disinfectant to spray and sterilize it evenly. Reduced to salt and water, no residual hazard;

[0028] S3. After ten minutes, soak the raw material with 75 degree edible alcohol to emulsify it, and take it out for granulation after 72 hours;

[0029] S4. Extreme dehumidification and drying, use ozone to sterilize once in the dehumidification and drying process, and then put it into a sealed container for cold storage;

[0030] S5. The raw ingredients are sprayed and sterilized with edible alcohol again before use;

[0031] S6. Ozone sterilization once again before the finished product is loaded ...

Embodiment 2

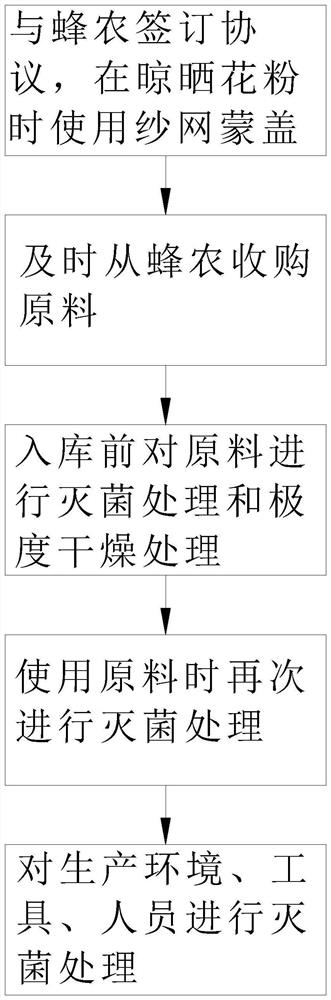

[0034] like figure 2 As shown, the present invention proposes a novel process technology method for the production of bee pollen tablets at a constant temperature of 37 degrees, compared to Embodiment 1, in S1, the acquisition of bee pollen raw materials includes the following steps:

[0035] S11. Sign an agreement with beekeepers to cover with gauze when the beekeepers are drying pollen to prevent flies from crawling;

[0036] S12. Purchase raw materials from beekeepers in time to shorten the storage time of raw materials in the hands of beekeepers; the microorganisms of pollen raw materials will double every 7 days when placed at room temperature, and the storage time of purchased raw materials in the hands of beekeepers does not exceed 7 days;

[0037] S13. The raw materials should be sterilized and extremely dried in time before entering the factory and put into storage, and the treated raw materials should be placed in the cold storage;

[0038] S14. Sterilize again whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com