Device and method for wet addition of zinc powder

A zinc powder, a part of the technology, applied in the field of zinc powder wet-adding devices, can solve the problems of zinc powder flying loss, environmental pollution, etc., and achieve the effect of solving the zinc powder flying loss

- Summary

- Abstract

- Description

- Claims

- Application Information

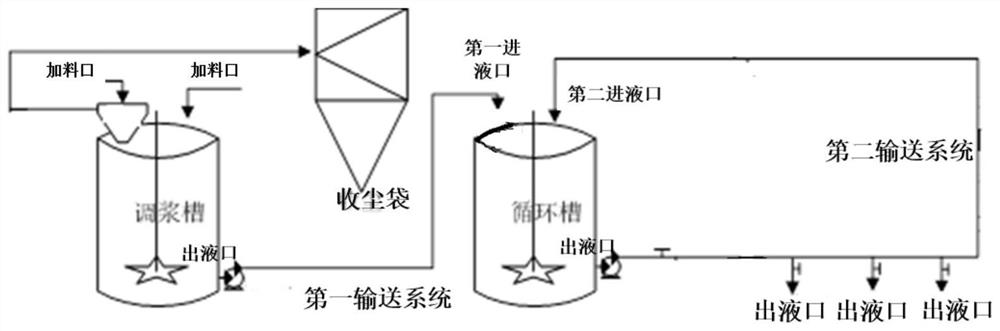

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] In this embodiment, sprayed zinc powder is used, with a particle size of 400 mesh.

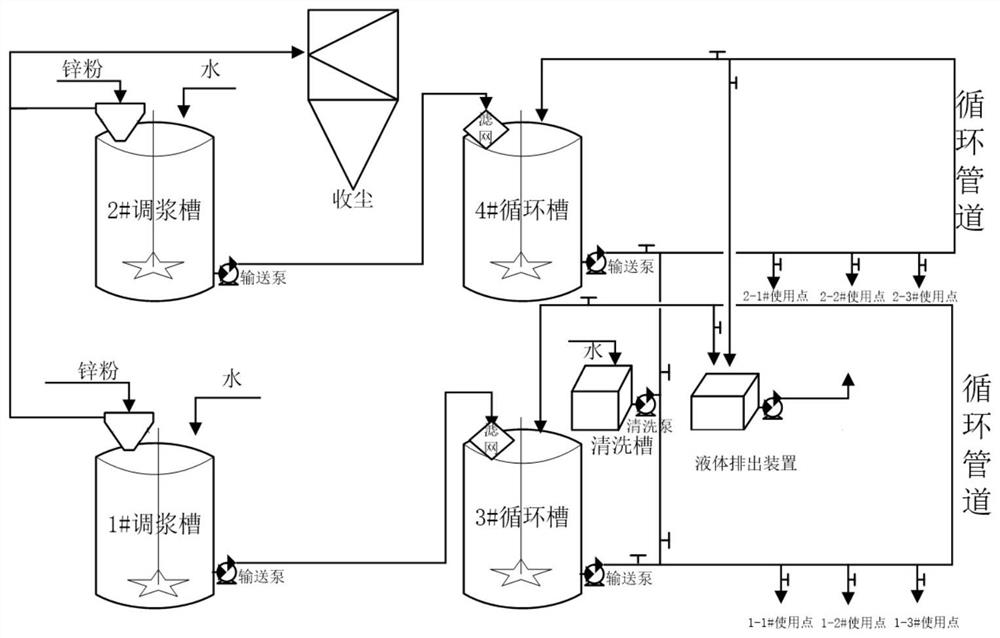

[0073] Such as figure 2 As shown, spray zinc powder and water according to the mass ratio of 1:4 (accurately weigh the mass of zinc powder through the electronic scale set at the powder filling port, and use the water meter set at the water filling port to control the water consumption) respectively from the powder feeding The mouth and the water inlet are added to the pulping tank 1# and the pulping tank 2# for pulping for 0.5h. At the same time, there is a dust collection bag above the pulping tank to collect the flying zinc powder to ensure the surrounding environment of the powder adding point. The dust content does not exceed the standard.

[0074] The zinc powder slurry obtained after pulping in pulping tank 1# and pulping tank 2# is pumped to the circulation tank respectively through the conveying pipeline by means of the delivery pumps connected to pulping tank 1# and pulping ...

Embodiment 2

[0078] In this embodiment, electric furnace zinc powder is used, with a particle size of 200 mesh.

[0079] Such as figure 2As shown, according to the mass ratio of 1:2.5 (accurately weigh the quality of the zinc powder through the electronic scale set at the powder adding port, use the water meter set at the powder adding port to control the water consumption) respectively from the powder adding port and water according to the mass ratio of 1:2.5. The water inlet is added to the pulping tank 1# and the pulping tank 2# for pulping for 0.5h. At the same time, there is a dust collection bag above the pulping tank to collect the flying zinc powder in it to ensure the dust in the surrounding environment of the powder adding point. The content does not exceed the standard.

[0080] The zinc powder slurry obtained after pulping in pulping tank 1# and pulping tank 2# is pumped to the circulation tank respectively through the conveying pipeline by means of the delivery pumps connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com