Method for etching NiCrSi film through wet process

A technology of wet etching and etching grooves, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as excessive point defects on the surface of silicon wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In the following, the present invention will be further described in detail in conjunction with the NiCrSi wet etching process implemented in detail.

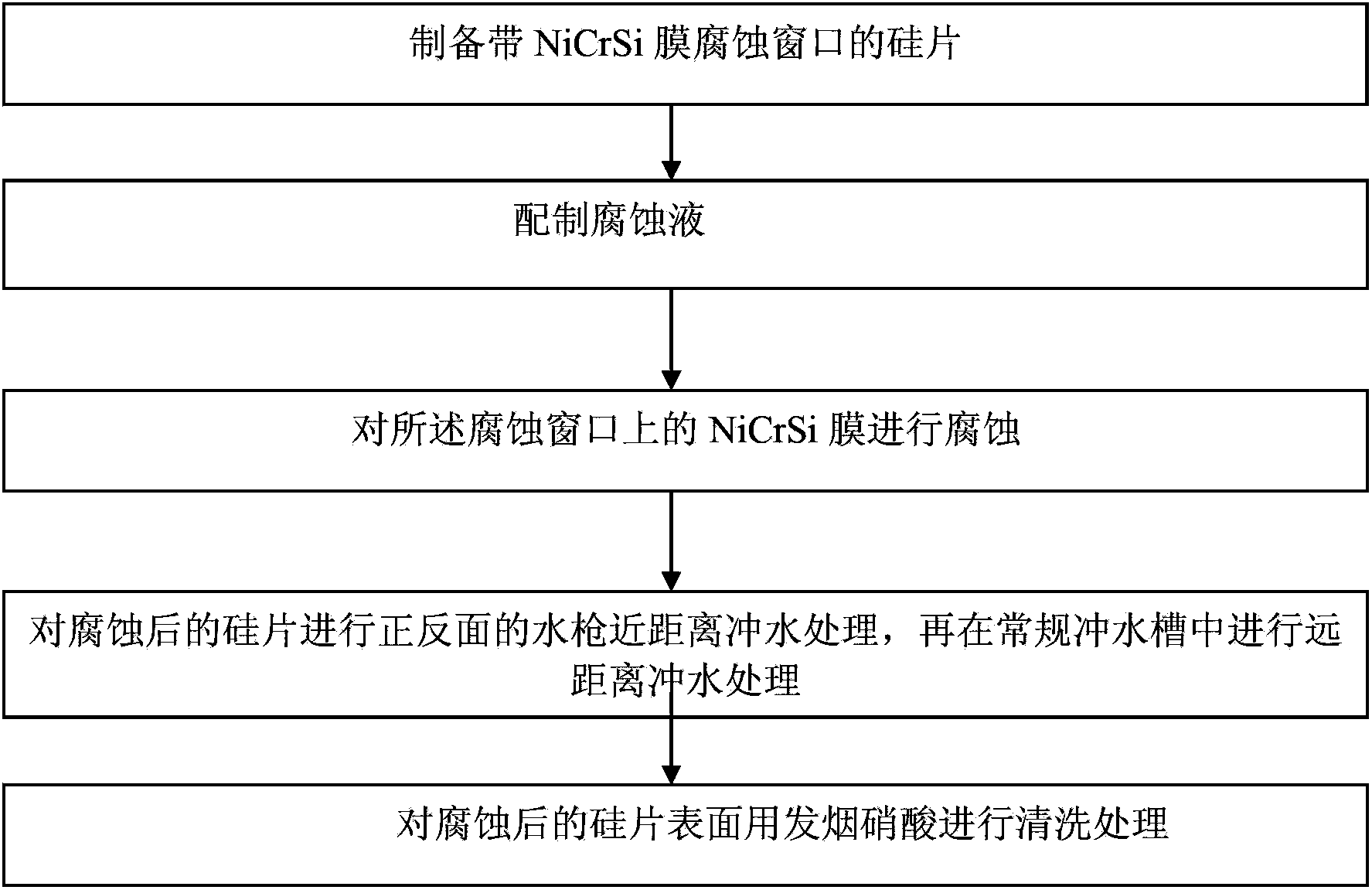

[0052] The technological process of wet etching NiCrSi film of the present invention is as figure 1 shown. The method step of wet etching NiCrSi of the present invention is as follows:

[0053] 1. Prepare a silicon wafer with a NiCrSi film corrosion window.

[0054] 1) Through the process before conventional semiconductor metallization, the product structure before conventional metallization is formed on the single crystal silicon polished wafer;

[0055] 2) Deposit a layer of NiCrSi film with a thickness of 20nm-30nm by using a conventional metallization process;

[0056]3) Carry out the conventional photolithography process, glue coating, exposure, development, and form photoresist as a masking layer, and the NiCrSi film without photoresist as the silicon wafer of the etching window.

[0057] Second, the preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com