Optimized self-control method and system for industrial enterprise emission pollution

An enterprise and industrial technology, applied in the field of optimized self-control methods and systems for industrial enterprises to discharge pollution, can solve the problems of exceeding the standard, waste of liquid ammonia for exporting nitrogen oxides, and a large amount of manpower, etc., achieving strong portability, saving manpower and injecting ammonia. Dosage, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

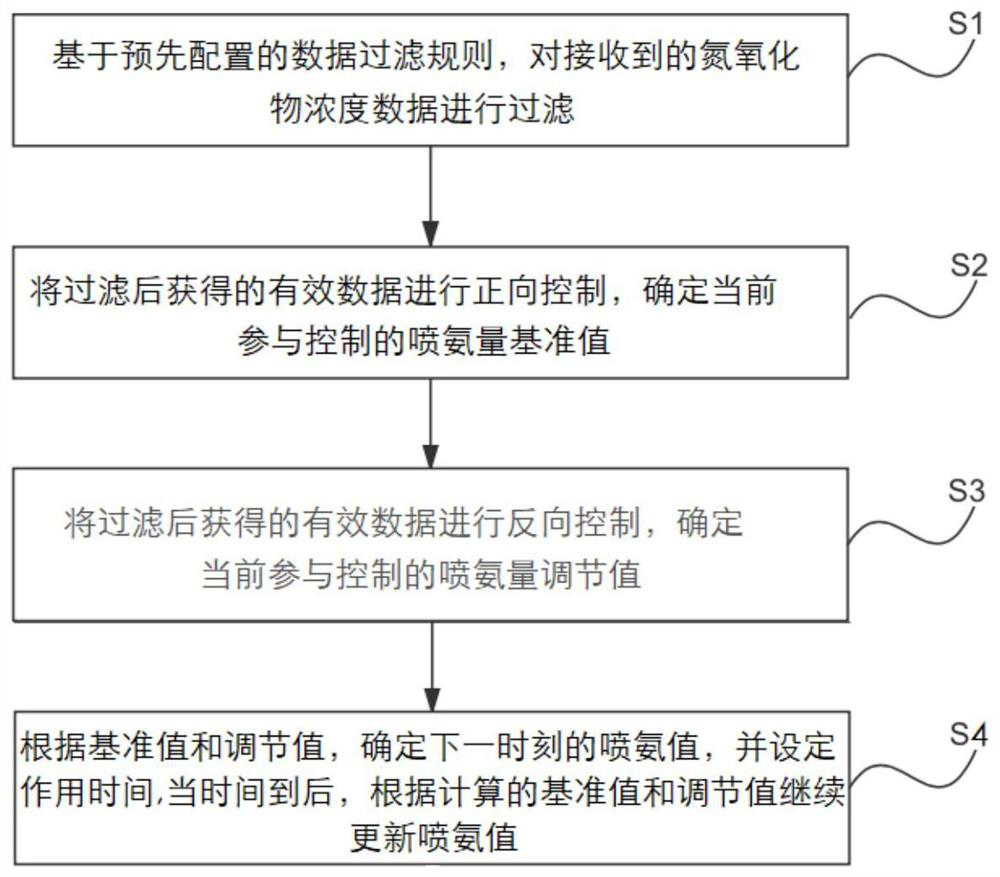

[0058] like figure 1 As shown, the specific steps of the method include:

[0059] S1, based on pre-configured data filtering rules, filtering the received nitrogen oxide concentration data;

[0060] S2, carry out positive control on the effective data obtained after filtering, and determine the reference value of the ammonia injection amount currently participating in the control;

[0061] S3, perform reverse control on the effective data obtained after filtering, and determine the adjustment value of the ammonia injection amount currently participating in the control;

[0062] S4. Determine the ammonia injection value at the next moment according to the reference value and the adjustment value, and set the action time. When the time is up, continue to update the ammonia injection value according to the calculated reference value and adjustment value.

[0063] The nitrogen oxide concentration data in step S1 includes: inlet nitrogen oxide data, ammonia injection amount data,...

Embodiment 2

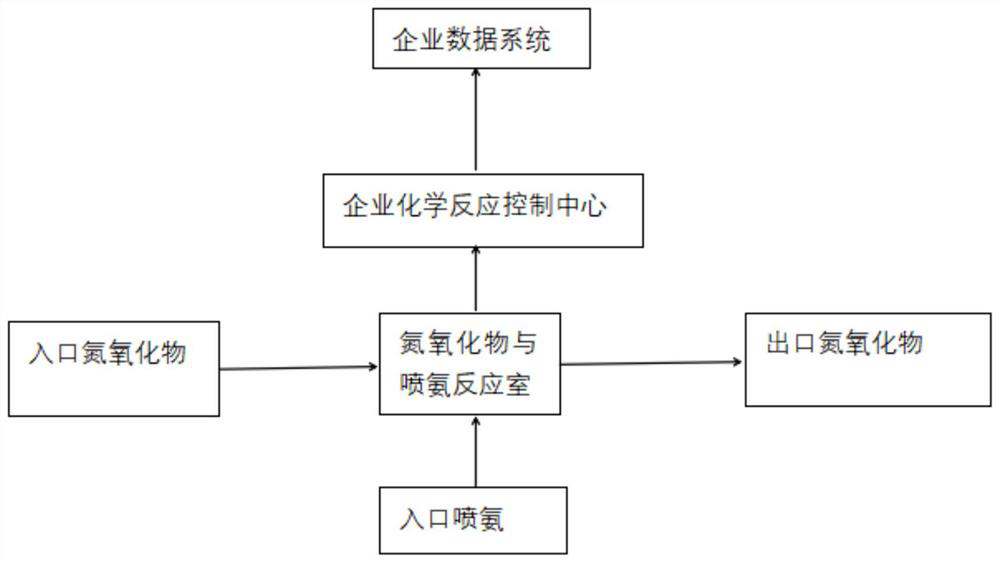

[0077] Based on the same inventive concept, the present invention also provides an optimized automatic control system for industrial enterprises to discharge pollution, which is characterized in that it includes:

[0078] A filtering module, configured to filter the received nitrogen oxide concentration data based on pre-configured data filtering rules;

[0079] The first control module is used to perform forward control on the effective data obtained after filtering, and determine the reference value of the ammonia injection amount currently participating in the control;

[0080] The second adjustment module is used to reversely control the effective data obtained after filtering, and determine the adjustment value of the ammonia injection amount currently participating in the control;

[0081] Among them, the filtering module includes:

[0082] The comparison module is used to compare the size between the inlet nitrogen oxide data, the ammonia injection data, the outlet nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com