Clean room system for semiconductor manufacturing and multistage electric field dust removal method thereof

An electric field dust removal and clean room technology, applied in the field of air purification, can solve the problems of electrostatic dust removal efficiency and excessive ozone concentration, high power consumption of air purification technology, and inability to remove air, etc., and achieves low cost, small size, and power consumption. saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

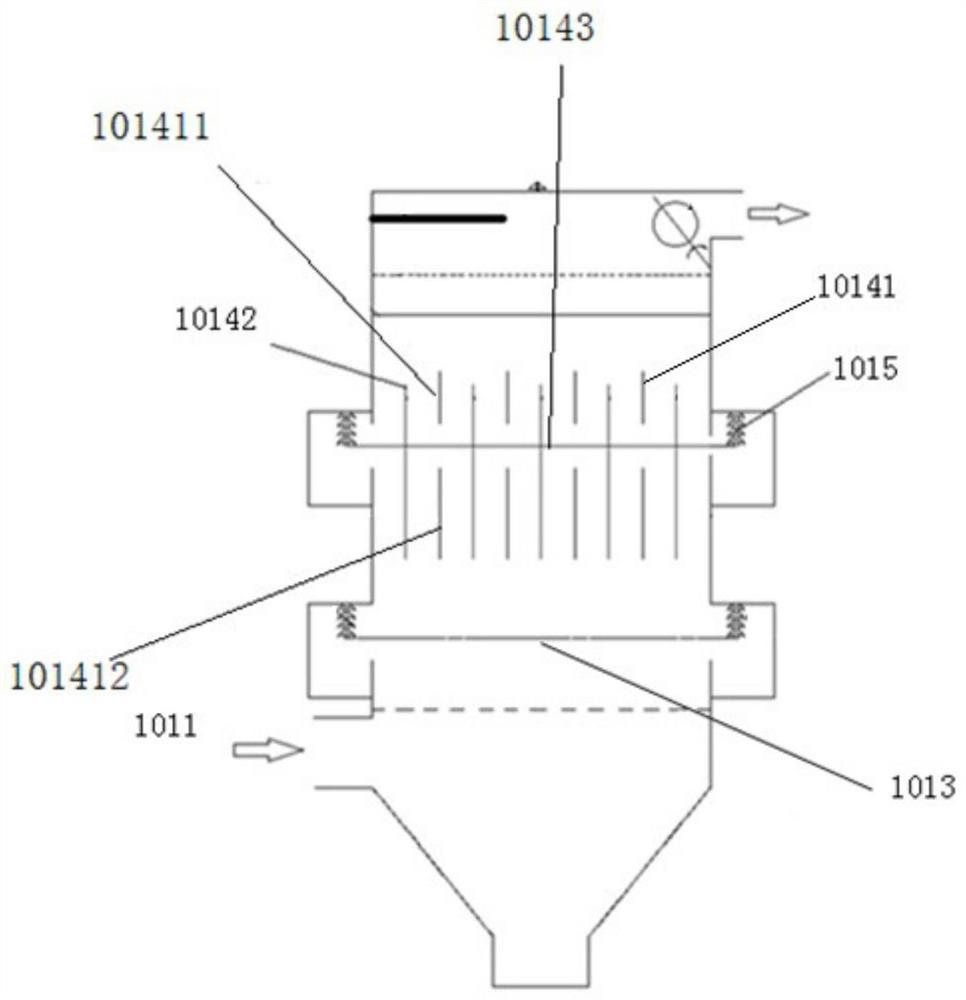

[0271] see figure 1 , which is a schematic structural diagram of the first-stage electric field device in the multi-stage electric field dust removal system of this embodiment. The electric field device includes an electric field device inlet 1011 , a front electrode 1013 , and an insulating mechanism 1015 .

[0272] The front electrode 1013 is arranged at the entrance 1011 of the electric field device. The front electrode 1013 is a conductive mesh plate, and the conductive mesh plate is used to conduct electrons to the gas with strong conductivity after power on. pollutants such as metal dust, mist droplets, or aerosols, the anode dust accumulation part of the electric field device, that is, the electric field anode 10141, attracts charged pollutants, and makes the charged pollutants move to the electric field anode until this part of the pollutants Attached to the electric field anode, this part of the pollutants are collected.

[0273] The electric field device includes a...

Embodiment 2

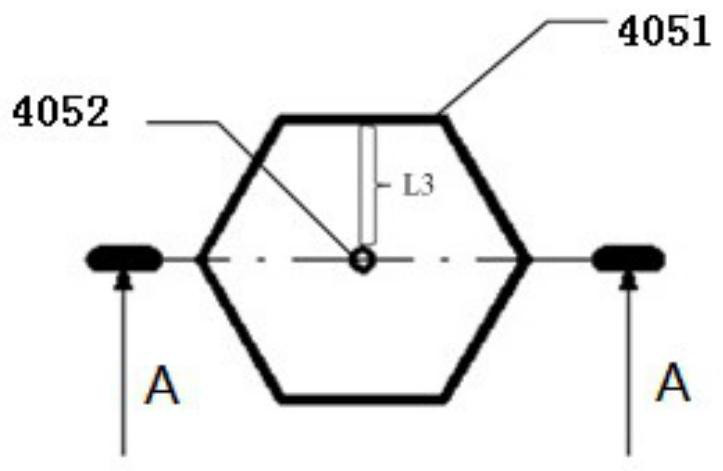

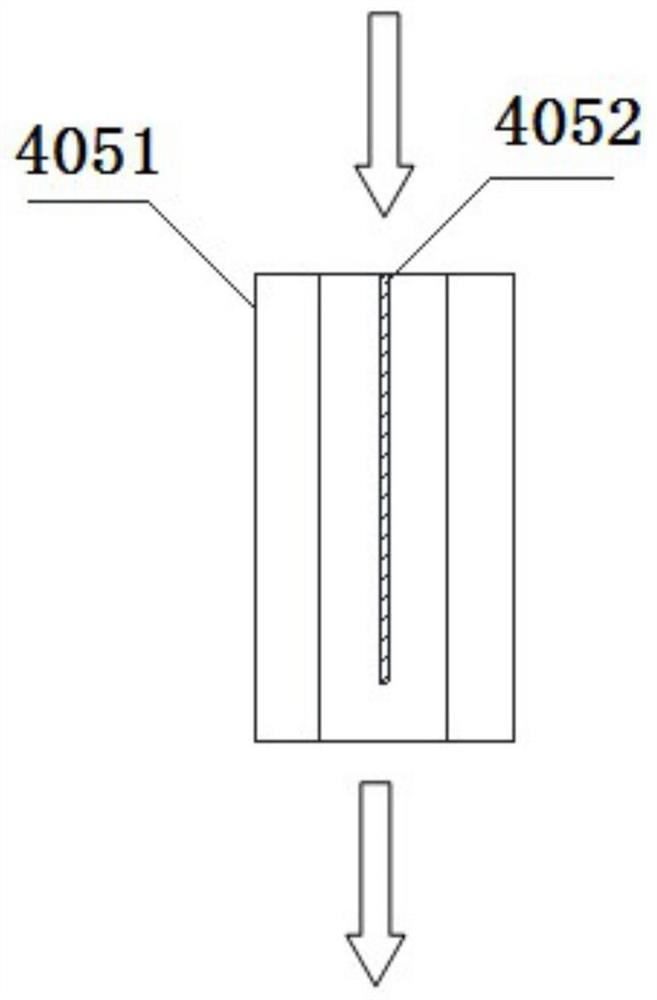

[0280] The electric field generating unit in this embodiment can be applied to the first-stage electric field device in the multi-stage electric field dust removal system of the semiconductor manufacturing clean room system of the present invention. The structure diagram of the electric field generating unit in this embodiment can be found in figure 2 , the A-A view of the electric field generating unit in this embodiment can be found in image 3 , the A-A view of the electric field generating unit of the electric field generating unit of the present embodiment marking length and angle is referred to Figure 4 .

[0281] Such as figure 2 As shown, it includes an electric field anode 4051 and an electric field cathode 4052 for generating an electric field, and the electric field anode 4051 and the electric field cathode 4052 are respectively electrically connected to two electrodes of a power supply, and the power supply is a DC power supply, and the electric field anode 405...

Embodiment 3

[0289] In this embodiment, the electric field generating unit can be applied to the first-stage electric field device in the multi-stage electric field dust removal system of the semiconductor manufacturing clean room system of the present invention, such as figure 2 As shown, it includes an electric field anode 4051 and an electric field cathode 4052 for generating an electric field, and the electric field anode 4051 and the electric field cathode 4052 are respectively electrically connected to two electrodes of a power supply, and the power supply is a DC power supply, and the electric field anode 4051 and the electric field cathode 4052 The electric field cathode 4052 is electrically connected to the anode and cathode of the DC power supply respectively. In this embodiment, the electric field anode 4051 has a positive potential, and the electric field cathode 4052 has a negative potential.

[0290] In this embodiment, the direct current power supply may specifically be a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com