Purification method of polyethylene glycol monomethyl ether-polylactic acid amphiphilic segmented copolymer for injection

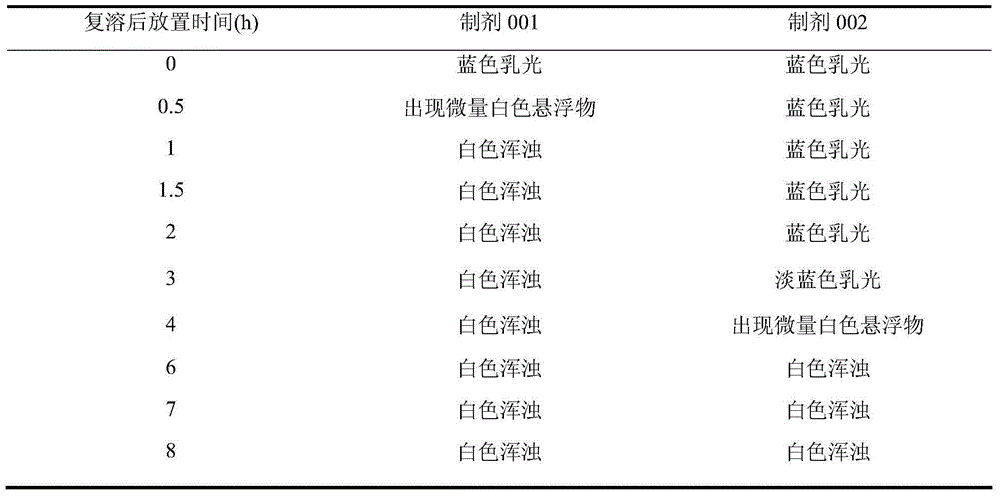

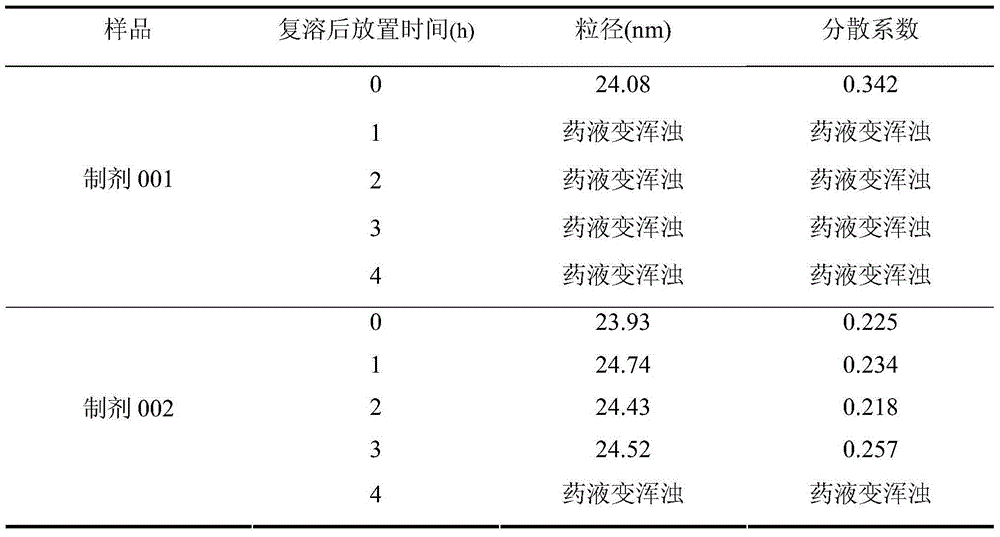

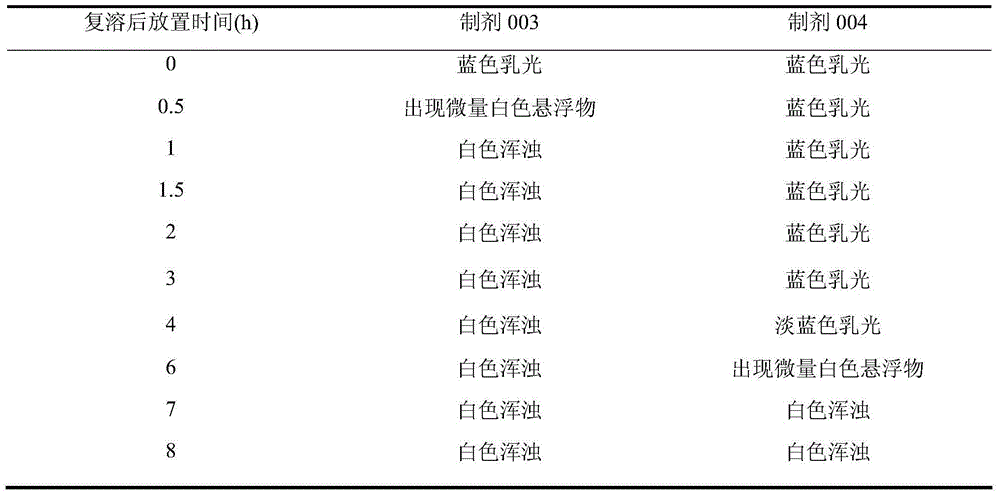

A technology of polyethylene glycol monomethyl ether and amphiphilic block, which is applied in the field of medicine and chemical industry, can solve the problems of poor reconstitution stability, slow dissolution and difficult production of polymer micellar freeze-dried preparations, and improve reconstitution Effects of stability, improvement of physical properties, and improvement of solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, preparation polyethylene glycol monomethyl ether-polylactic acid amphiphilic block copolymer (average molecular weight 4000)

[0021] Polyethylene glycol monomethyl ether (molecular weight 2000) and lactide were vacuum-dried for 12 hours under the conditions of a vacuum degree greater than 0.095MPa and a temperature of 40°C, and set aside; weigh polyethylene glycol monomethyl ether (molecular weight 2000) Add 30g of lactide, 30g of lactide and 0.15ml of stannous octoate into the reaction bottle, repeatedly fill with nitrogen, vacuumize, and then raise the temperature to 140°C for 6 hours; after the reaction is completed, cool to room temperature to obtain polyethylene glycol monomethyl ether -The crude product of polylactic acid amphiphilic block copolymer, recrystallize the crude product with dichloromethane-diethyl ether, filter the product and vacuum-dry it at room temperature for 72 hours to obtain polyethylene glycol monomethyl ether-polylactic acid am...

Embodiment 2

[0022] Embodiment 2, preparation polyethylene glycol monomethyl ether-polylactic acid amphiphilic block copolymer (average molecular weight 3000)

[0023] Polyethylene glycol monomethyl ether (molecular weight 2000) and lactide were vacuum-dried for 12 hours under the conditions of a vacuum degree greater than 0.095MPa and a temperature of 40°C, and set aside; weigh polyethylene glycol monomethyl ether (molecular weight 2000) Add 30g of lactide, 15g of lactide and 0.15ml of stannous octoate into the reaction bottle, repeatedly fill with nitrogen, vacuumize, and then raise the temperature to 140°C for 6 hours; after the reaction is completed, cool to room temperature to obtain polyethylene glycol monomethyl ether -The crude product of polylactic acid amphiphilic block copolymer, recrystallize the crude product with dichloromethane-diethyl ether, filter the product and vacuum-dry it at room temperature for 72 hours to obtain polyethylene glycol monomethyl ether-polylactic acid am...

Embodiment 3

[0024] Embodiment 3: prepare polyethylene glycol monomethyl ether-polylactic acid amphiphilic block copolymer (average molecular weight 6000)

[0025] Polyethylene glycol monomethyl ether (molecular weight 2000) and lactide were vacuum-dried for 12 hours under the conditions of a vacuum degree greater than 0.095MPa and a temperature of 40°C, and set aside; weigh polyethylene glycol monomethyl ether (molecular weight 2000) Add 20g of lactide, 40g of lactide and 0.15ml of stannous octoate into the reaction bottle, repeatedly fill with nitrogen, vacuumize, and then raise the temperature to 140°C for 6 hours; after the reaction is completed, cool to room temperature to obtain polyethylene glycol monomethyl ether -The crude product of polylactic acid amphiphilic block copolymer, recrystallize the crude product with dichloromethane-diethyl ether, filter the product and vacuum-dry it at room temperature for 72 hours to obtain polyethylene glycol monomethyl ether-polylactic acid amphip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com