Novel environment-friendly waste gas treatment system for paint spraying and baking equipment

A waste gas treatment and paint-baking technology, which is applied in the direction of injection devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of not meeting the requirements of environmental protection testing, incomplete removal of solids, and affecting the use effect, so as to achieve no special management And daily maintenance, energy saving, low wind resistance of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

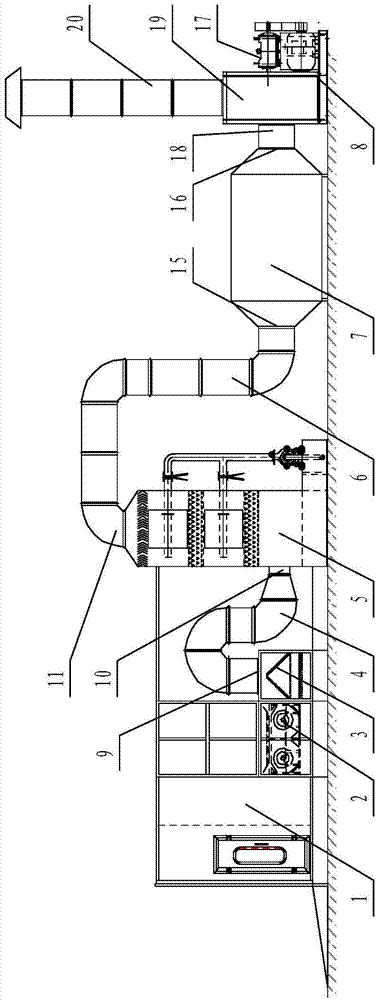

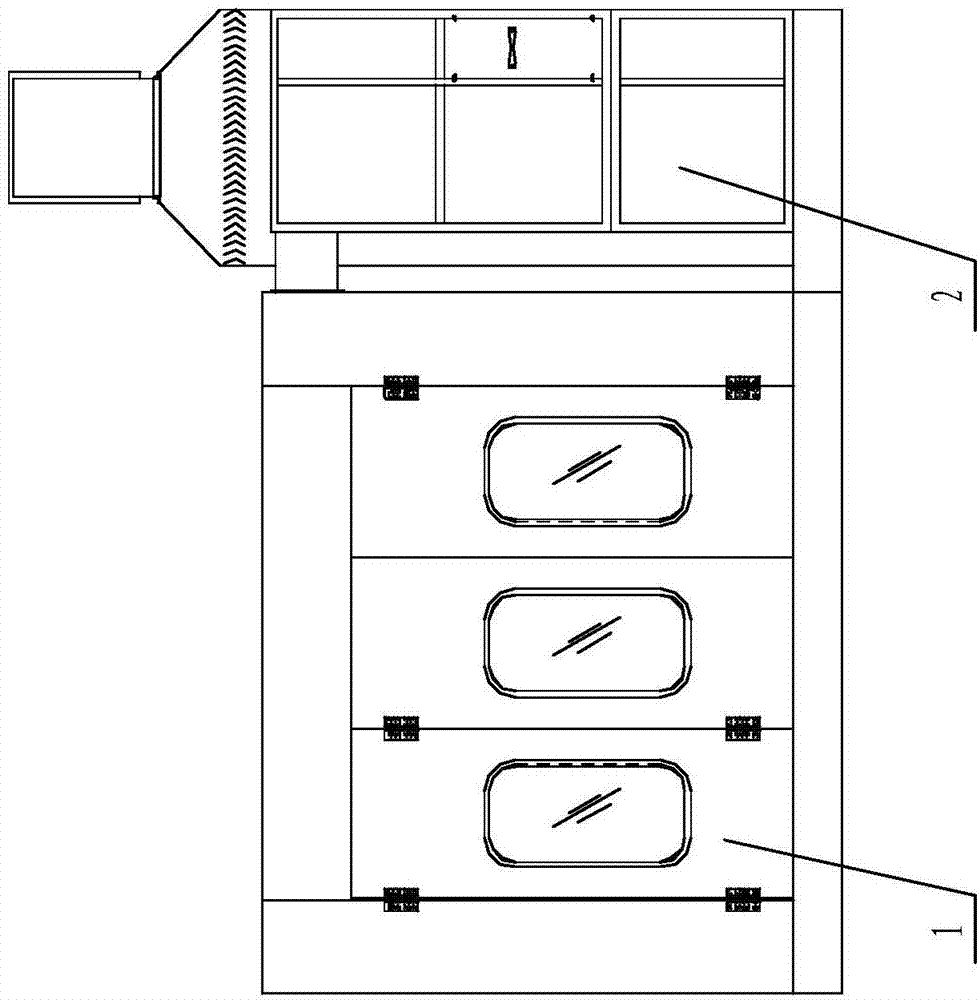

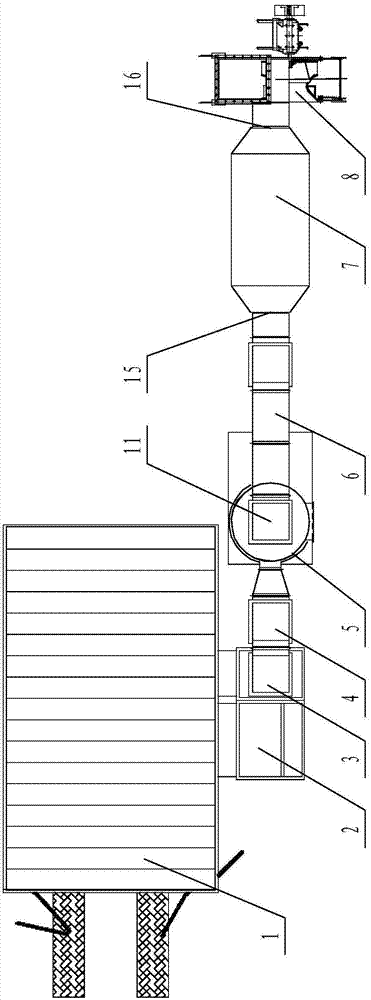

[0030] In order to further illustrate the above-mentioned purpose, technical scheme and effect of the present invention, the present invention will be described below in conjunction with the accompanying drawings and relevant known technical knowledge through the embodiments:

[0031] Such as Figure 1-3 As shown, the exhaust gas treatment system of this new type of environmental protection technology spraying and baking equipment includes a spraying and baking paint circuit control system, a room body 1, an air supply device 2, a gas collecting cabinet 3, and an exhaust device 8; the room body 1 includes a lighting system, a primary adsorption Glass wool, ground grille, top filter device, static plenum, operating room; air supply device 2 includes blower base, heating device, air supply bell mouth, the air supply bell mouth on the top of air supply device 2 and the top of room body 1 The static pressure chambers are connected, the bottom of the air supply device 2 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com