Hot air drying system increasing concentration and saving energy

A technology of hot air drying and drying oven, which is applied in the direction of drying solid materials, drying gas arrangement, drying, etc., which can solve the problems of hot air consumption, energy consumption, and non-utilization, so as to reduce investment and operating costs, increase basic temperature, The effect of size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

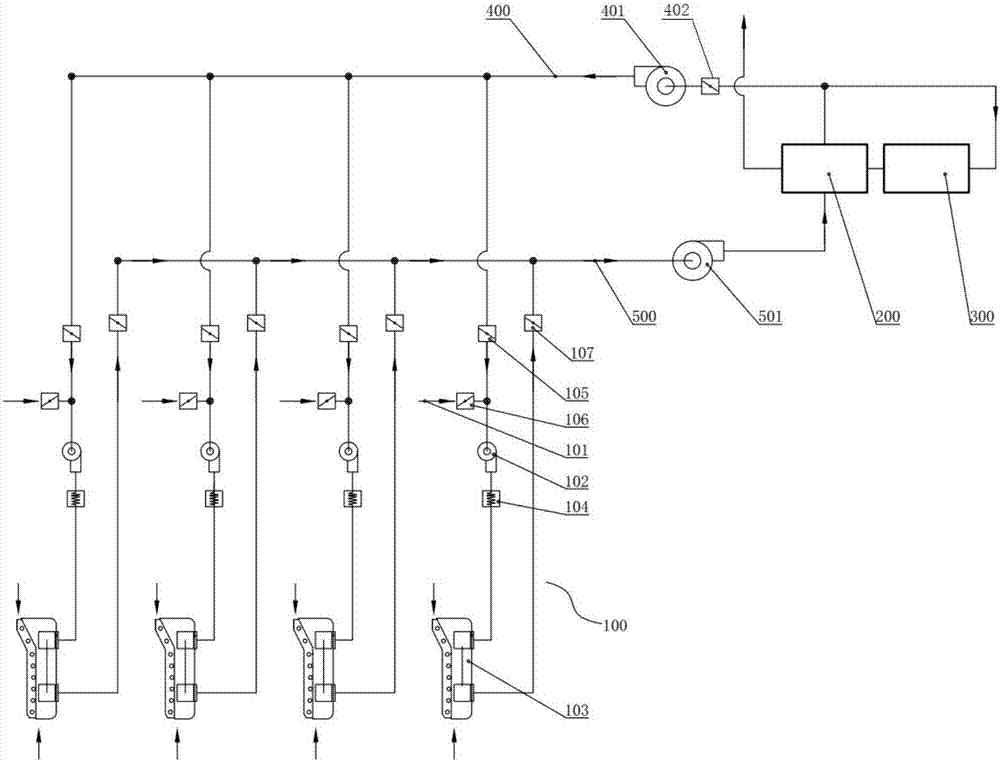

[0023] Embodiment 1: Take the hot air drying system with multiple unit independent enrichment and energy saving as an embodiment, see figure 1 , to describe the implementation of the thickening and energy-saving hot air drying system.

[0024] The concentrated and energy-saving hot air drying system of this embodiment includes a hot air drying unit 100, a heat exchanger 200, an end treatment device 300, an air supply main pipe 400 and an exhaust air main pipe 500, and the hot air drying unit 100 includes an environmental waste gas inlet pipe 101 , unit blower fan 102 and drying box 103, the air inlet of described unit blower fan 102 is communicated with described environmental waste gas inlet pipe 101, and the air outlet of described unit blower fan 102 is connected with the air inlet of described drying box 103 The air outlet of the drying box 103 communicates with the air inlet of the exhaust main pipe 500, the air outlet of the exhaust main pipe 500 communicates with the ai...

Embodiment 2

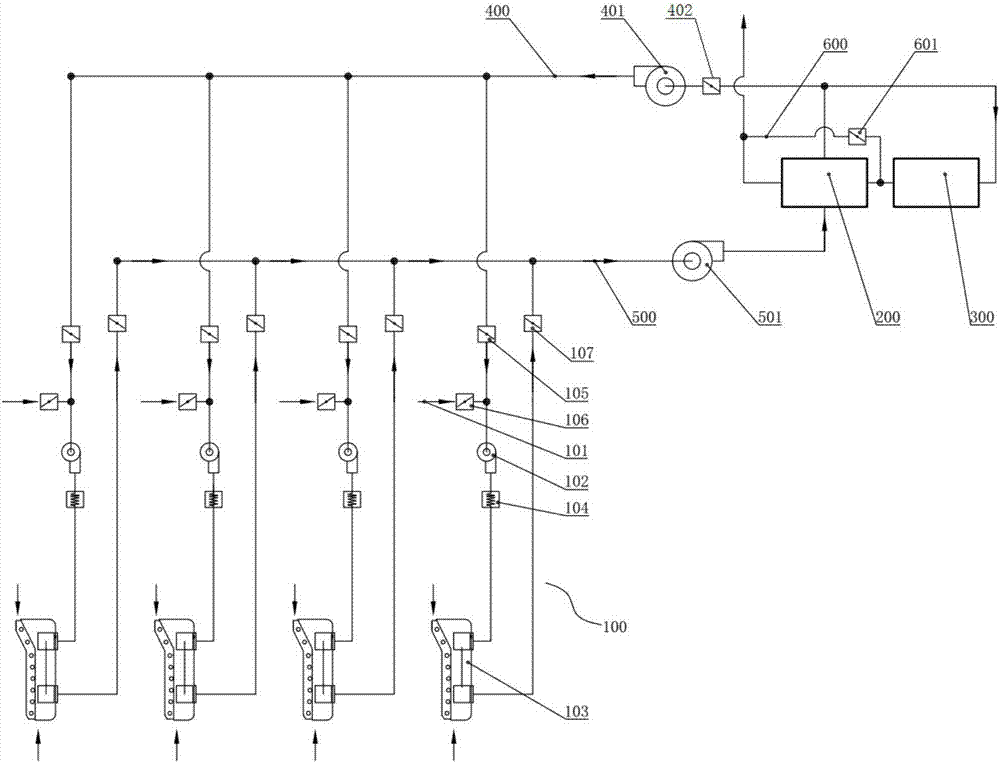

[0031] Embodiment 2: Take the hot air drying system with multiple unit independent enrichment and energy saving as an embodiment, see figure 2 , to describe the implementation of the thickening and energy-saving hot air drying system.

[0032] Compared with Example 1, the main difference between the enriched and energy-saving hot air drying system of Example 2 is that a bypass is connected between the air outlet of the terminal processing equipment 300 and the air outlet of the high temperature end of the heat exchanger 200 Pipeline 600, the second air volume regulating valve 601 is provided on the bypass pipe. Thus, the air volume entering the heat exchanger 200 is adjusted through the fourth air volume regulating valve of the bypass pipe, thereby controlling the temperature of the gas entering the main air supply pipe 400 and realizing stable operation of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com