An automatic cleaning, sterilization and disinfection system for sturgeon processing

An automatic cleaning, sterilization and disinfection technology, which is applied in the direction of fish cleaning/descaler, fish processing, liquid preservation of meat/fish, etc., can solve the problems of manpower consumption, physical injury, low production efficiency, etc., to avoid physical injury, manpower The effect of less effort and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

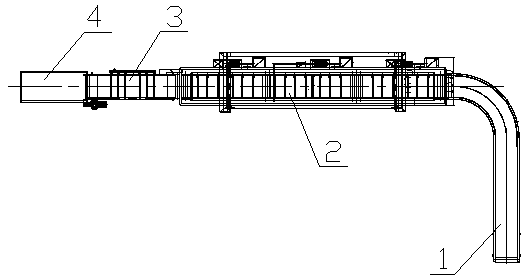

[0022] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0023] see figure 1 , an automatic cleaning, sterilization and disinfection system for sturgeon processing in this embodiment, including a conveyor connected to the cleaning workbench of the slaughtering line, and an electric control system. mechanism.

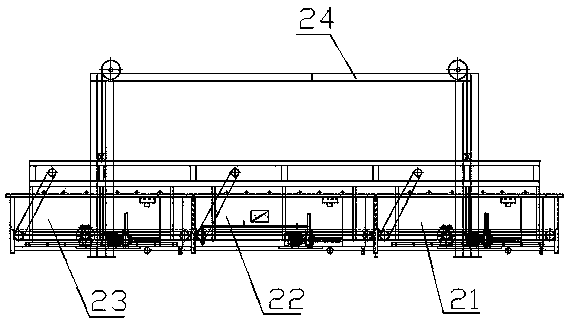

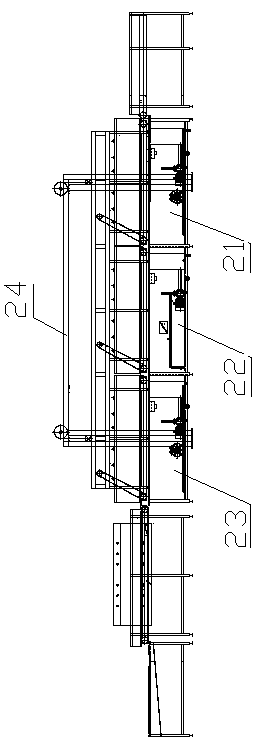

[0024] The three-stage cleaning and sterilization mechanism is composed of bubble cleaning process, potion sterilization process and rinsing process.

[0025] The three-stage cleaning and sterilization mechanism has the same upper and lower stations, of which the upper station is three independent horizontal conveying positions, and these three independent horizontal conveying positions are sequentially connected in sequence to ensure the smooth transition of the fish body from one station Go to the next station; the next station is the cleaning and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com