Method for preparing liquid chlorine dioxide disinfectant and device thereof

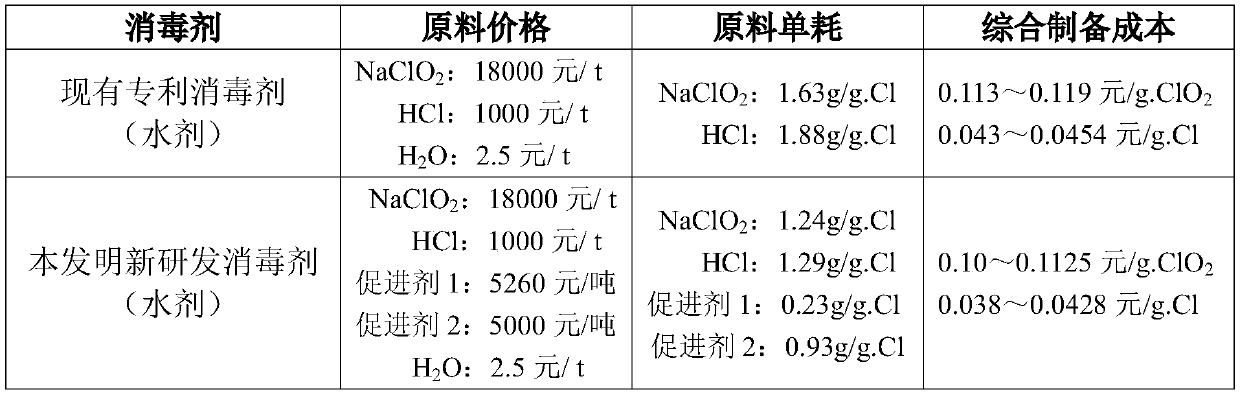

A chlorine dioxide and disinfectant technology, applied in the chemical industry, can solve the problems of high preparation cost and high price, and achieve the effects of reducing the preparation cost, reducing the amount of hydrochloric acid, and reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

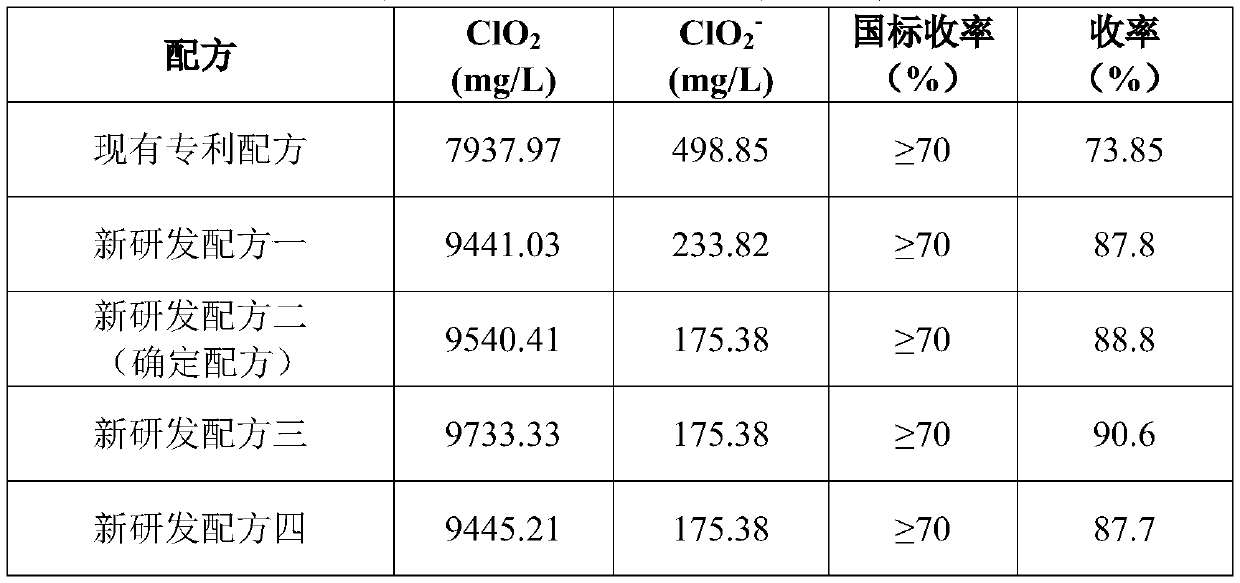

Examples

Embodiment 1

[0039] A method for preparing a liquid chlorine dioxide disinfectant, comprising the steps of: preparing agent A and agent B respectively, adding the two together to a dosing device for activation reaction, and continuously aerating to produce high-purity, Highly active chlorine dioxide gas is sent to drinking water application sites through dosing equipment;

[0040] Wherein, agent A is sodium chlorite solution, agent B is a mixed solution of hydrochloric acid, including hydrochloric acid solution, accelerator I and accelerator II, accelerator I is citric acid, and accelerator II is oxalic acid.

[0041] In agent B, the mass ratio of hydrochloric acid to the sum of citric acid and oxalic acid is 1:0.255-0.5, and the mass ratio of citric acid and oxalic acid is 1:3.6-8.0; the reaction volume ratio of agent A and agent B is 1: 1.01 to 1.04, the temperature of the activation reaction is normal temperature, and the time of the activation reaction is 15 to 20 minutes.

Embodiment 2

[0043] In Example 1, agent B is preferably configured using the following device:

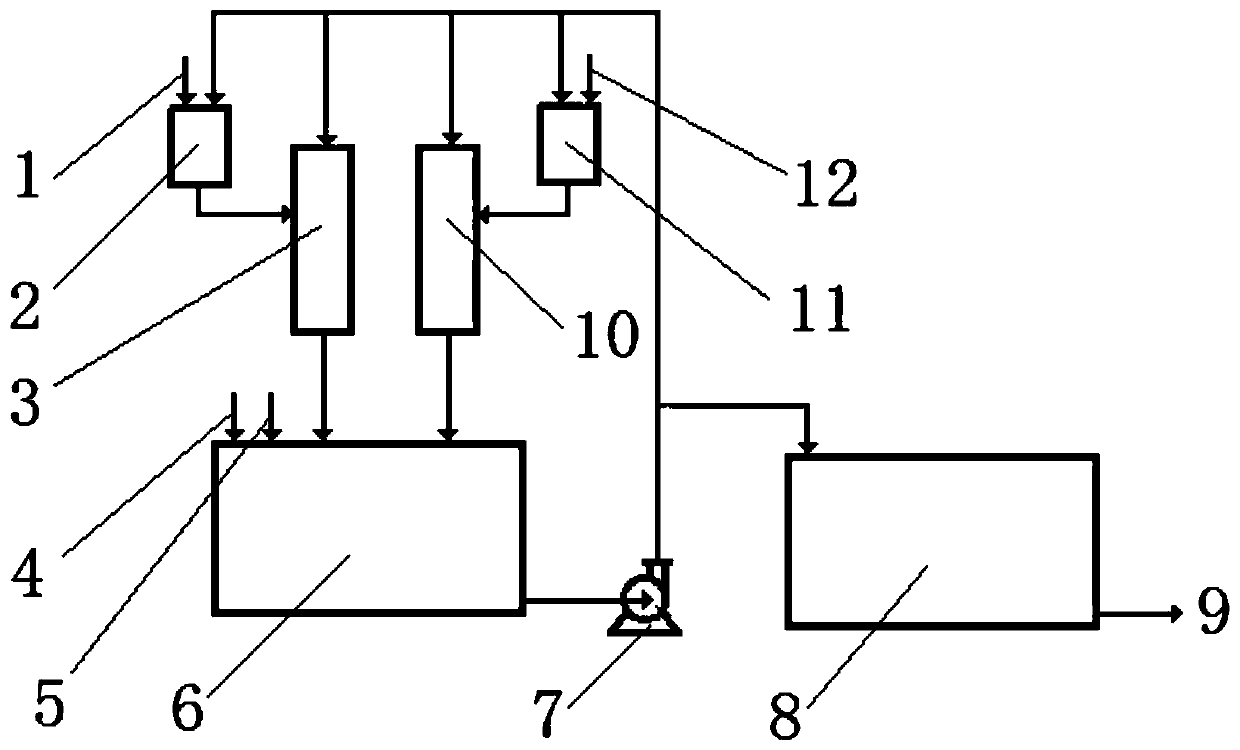

[0044] A preparation device for hydrochloric acid mixed solution, comprising hydrochloric acid dilution mixing tank 6 and the first hydrochloric acid mixer 3 and the second hydrochloric acid mixer 10 connected to it respectively, the first hydrochloric acid mixer 3 links to each other with accelerator 1 dissolution tank 2, the second Dihydrochloric acid mixer 10 links to each other with accelerator II dissolution tank 11;

[0045] The hydrochloric acid dilution mixing tank 6 is connected with the circulation pump 7, and the circulation pump 7 is respectively connected with the finished product tank 8, the first hydrochloric acid mixer 3, the accelerator I dissolution tank 2, the second hydrochloric acid mixer 10 and the accelerator II dissolution tank 11 through pipelines connected.

[0046] On hydrochloric acid dilution mixing tank 6, be provided with hydrochloric acid solution inlet 4 and wa...

Embodiment 3

[0050] Adopt the method for preparing the hydrochloric acid mixed solution of the preparation device of the hydrochloric acid mixed solution of embodiment 2, may further comprise the steps:

[0051] Step 1. Pour the hydrochloric acid into the hydrochloric acid dilution mixing tank 6 filled with water, and add citric acid, oxalic acid, and hydrochloric acid to the accelerator I dissolving tank 2 and the accelerator II dissolving tank 11 at a mass ratio of 1:3.6 to 8.0. The mass ratio to the sum of citric acid and oxalic acid is 1:0.255~0.5; close the first valve, the third valve and the fourth valve, open the second valve and the fifth valve, and fully mix under the action of the circulation pump 7 (about 30 minutes of mixing);

[0052] Step 2, open the third valve and the fourth valve, continue to fully mix (about 4 hours of mixing);

[0053] Step 3: After obtaining the hydrochloric acid mixed solution that meets the requirements, close the second valve, the third valve, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com