Method for automatically controlling nitrogen oxide concentration of denitrification system

A technology for nitrogen oxides and automatic control devices, applied in the direction of non-electric variable control, chemical instruments and methods, multiple fluid ratio control, etc., can solve the problem of excessive ammoniacal nitrogen, waste of urea, and inability to achieve stable control of nitrogen oxides, etc. problems, to achieve the effect of saving the amount of dosage, ensuring that the standard is not exceeded, and saving the amount of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

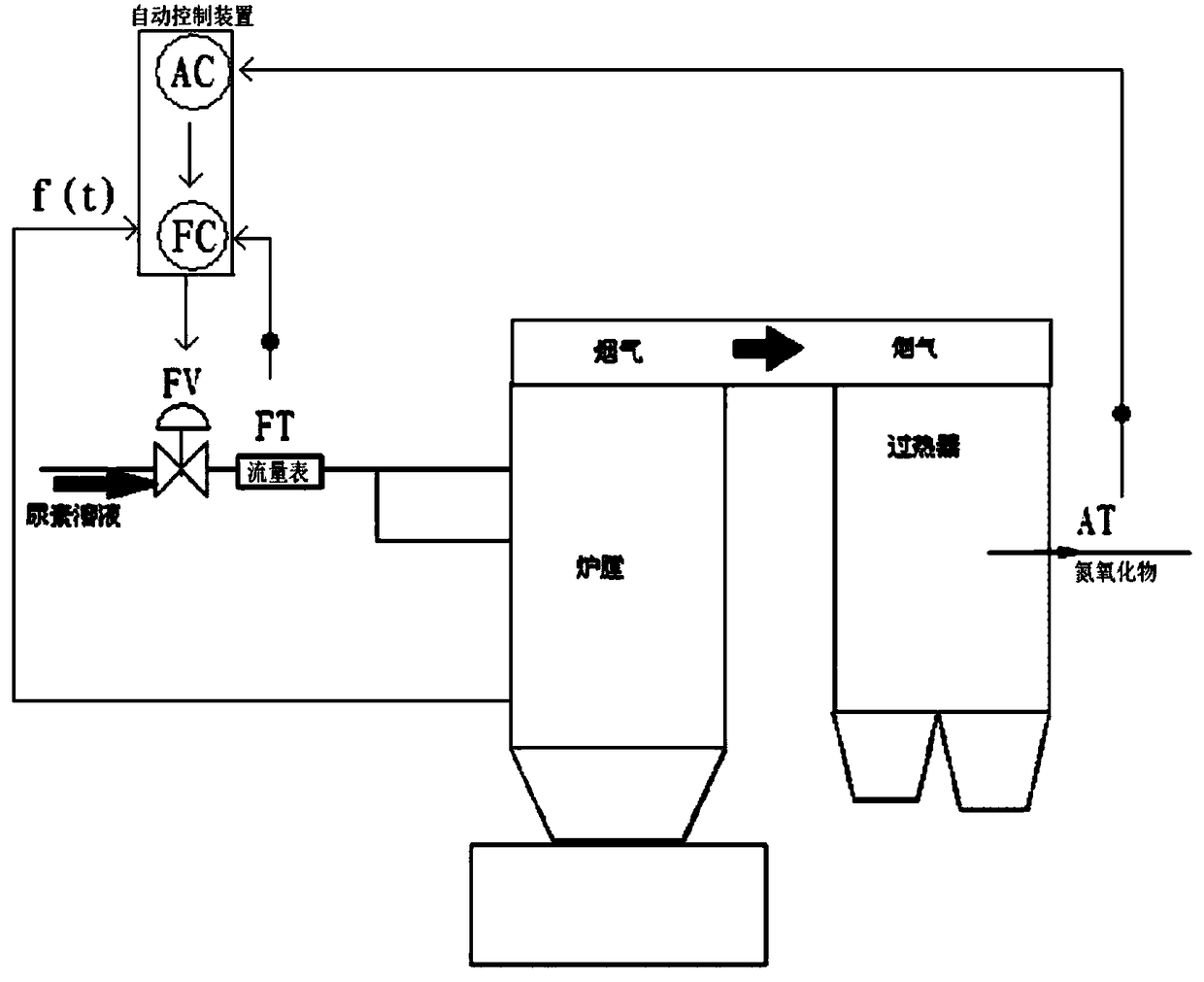

[0041] Such as figure 1 As shown, the nitrogen oxide concentration automatic control method of the present invention, its applicable denitration system is provided with a urea solution supply system, a regulating valve FV, a boiler, a flow meter, a temperature measuring device, a nitrogen oxide concentration measuring device and an automatic control device . Among them, the urea solution output by the urea solution supply system is input into the boiler through the regulating valve FV, the flow meter can measure the flow rate of the urea solution output by the regulating valve FV in real time, the temperature measuring device can measure the temperature of the combustion zone of the boiler in real time, and the nitrogen oxide concentration measuring device can Real-time measurement of the concentration of nitrogen oxides in the flue gas exhausted by the boiler, the automatic control device reads the data measured by the flow meter, temperature measurement device and nitrogen o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com