Plunger type supply device

A supply device, plunger-type technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of poor separation effect, low feeding speed, time-consuming and labor-intensive, etc., to achieve simple structure, fast supply speed, easy to use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

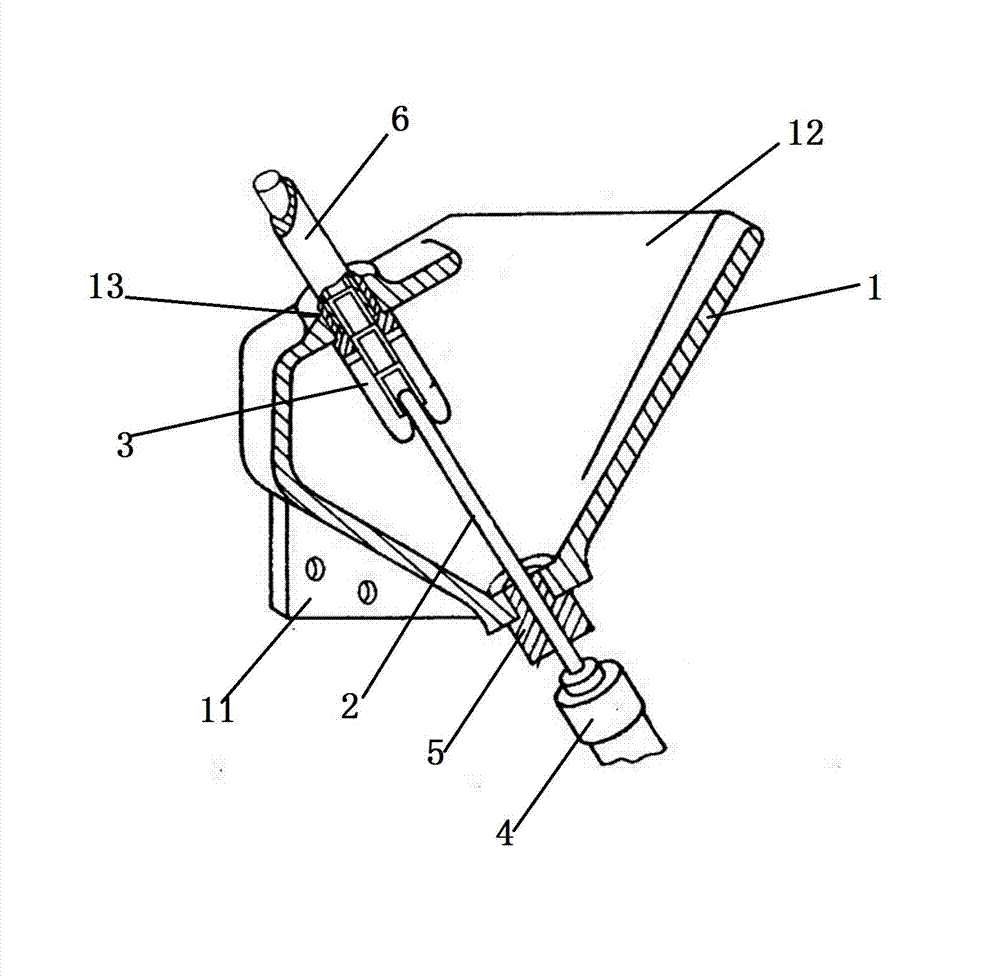

[0010] refer to figure 1 , a plunger type supply device, including a feeding mechanism, a separation mechanism and an output mechanism, the feeding mechanism includes a funnel 1, the funnel 1 is installed on the frame through a connecting plate 11, and the head of the funnel 1 has a feeding opening 12 And the discharge hole 13, the neck of the funnel 1 is a hollow columnar structure.

[0011] The separation mechanism includes a plunger 2, a clamp finger 3 and a cylinder 4 that controls the expansion and contraction of the plunger. The free end of the plunger 2 extends from the neck of the funnel 1, and the seal between the plunger 2 and the neck of the funnel 1 is sealed by a sealing plug 5. The clamp finger 3 is fixed on the inner side of the discharge hole 13, and the clamp finger 3 can accommodate workpieces arranged in a single row. Driven by the cylinder 4, the plunger 2 expands and contracts axially along the clamp finger 3, and pushes the workpiece in the head of the f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap