Improved large granule urea combined drum granulating method and equipment

A large-grain urea and drum granulation technology, which is applied to urea compound fertilizers, fertilizer mixtures, nitrogen fertilizers, etc., can solve the problems of high cost, energy consumption, and low efficiency, and achieve the goals of reducing energy consumption, reducing costs, and simplifying the process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described below in conjunction with the accompanying drawings.

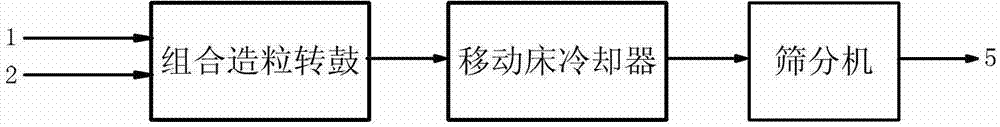

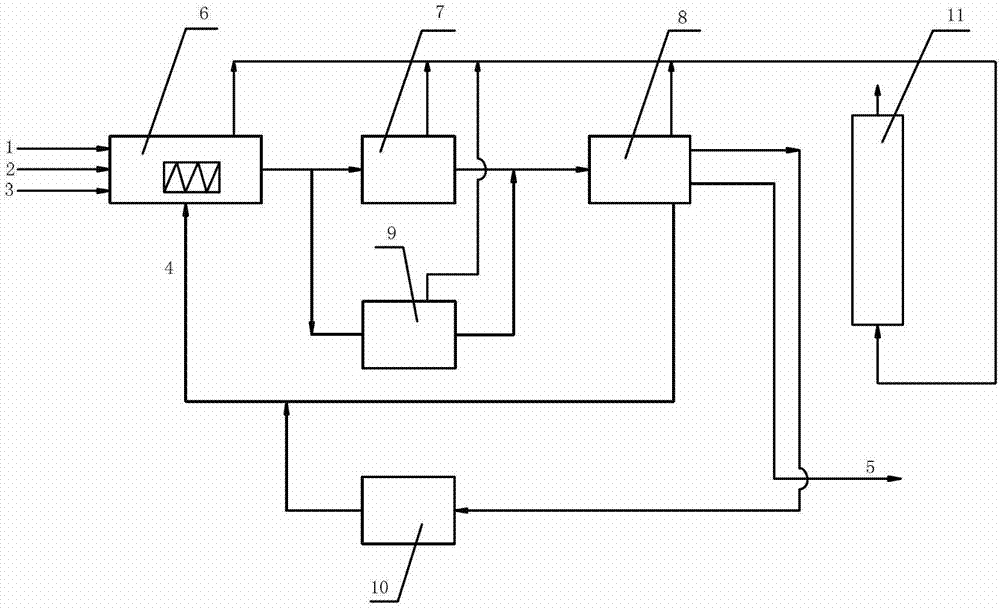

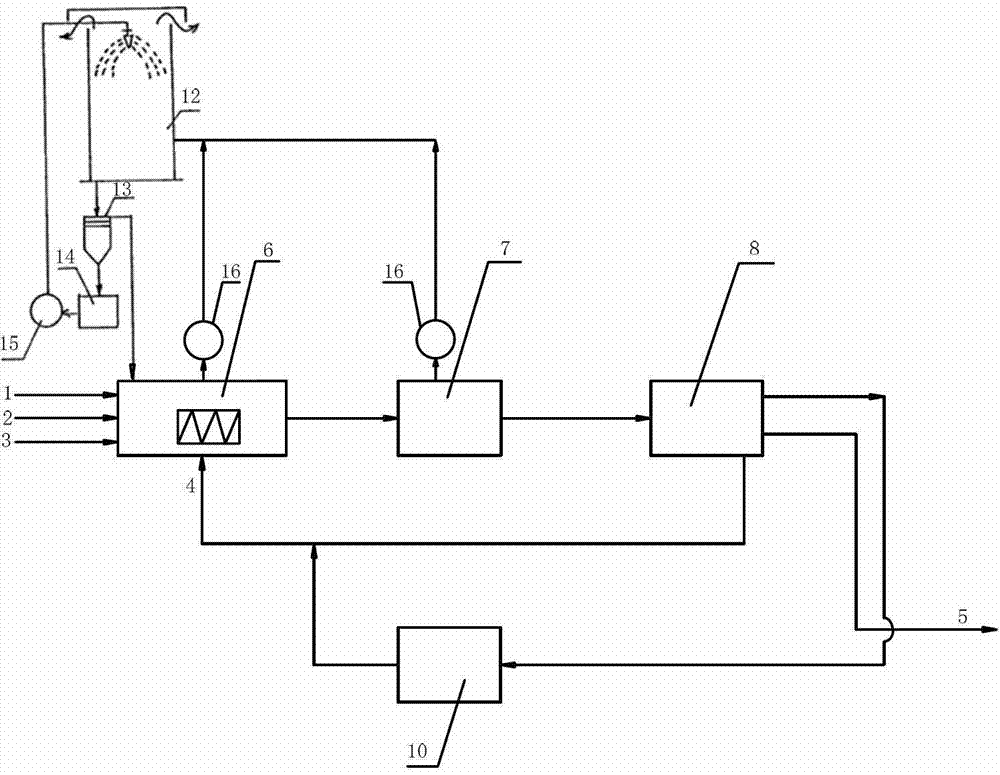

[0031] The present invention relates to an improved method for granulating large-grained urea in a combined drum. In the method, urea granules are generated and discharged in the fluidized bed of the combined granulation drum, and the discharged urea granules enter a moving bed cooler for cooling. After sifting through a sieving machine, the finished product is obtained, such as figure 1The flowchart shown. Both molten urea 1 and fluidizing air 2 are introduced into the combined granulation drum through pipelines, and in the fluidized bed of the combined granulation drum, the droplets of molten urea 1 are evenly sprayed on the surface of the urea crystal nucleus particles in the fluidized bed, Under the action of the fluidizing air 2 from bottom to top, the urea crystal nuclei particles are continuously increasing in the boiling state, and urea particles of different sizes ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com