Engine timing cover

An engine and cover technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of generalization and platformization of unfavorable parts, large distortion of oil gauge tube, and increase of engine cost, so as to save The effect of sealing O-ring, reducing the risk of oil leakage and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

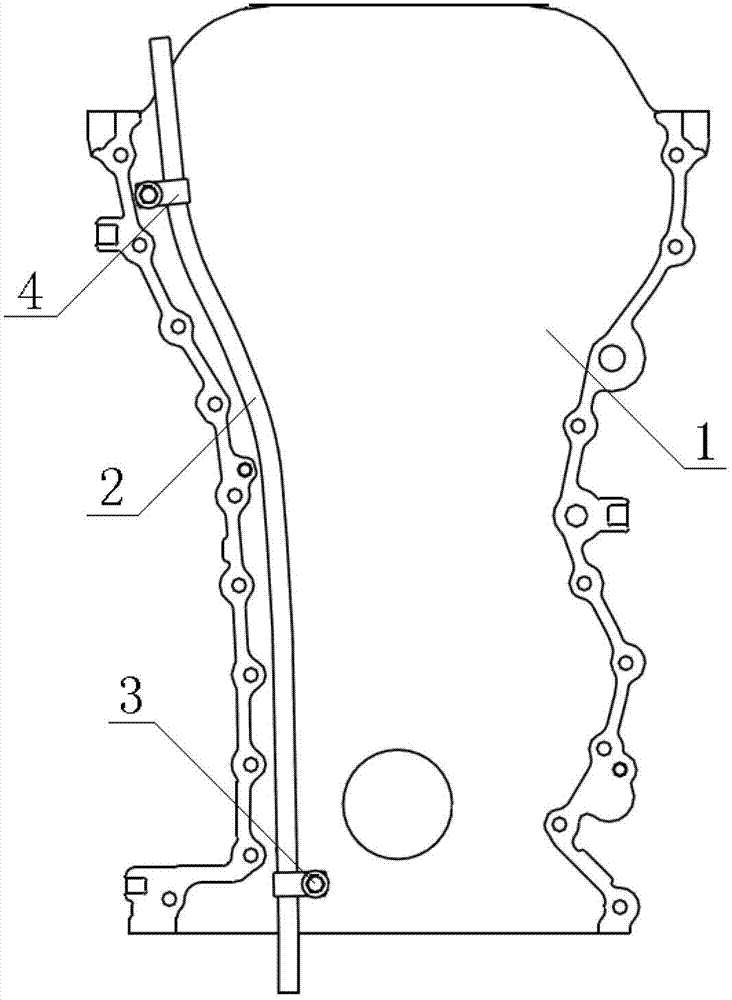

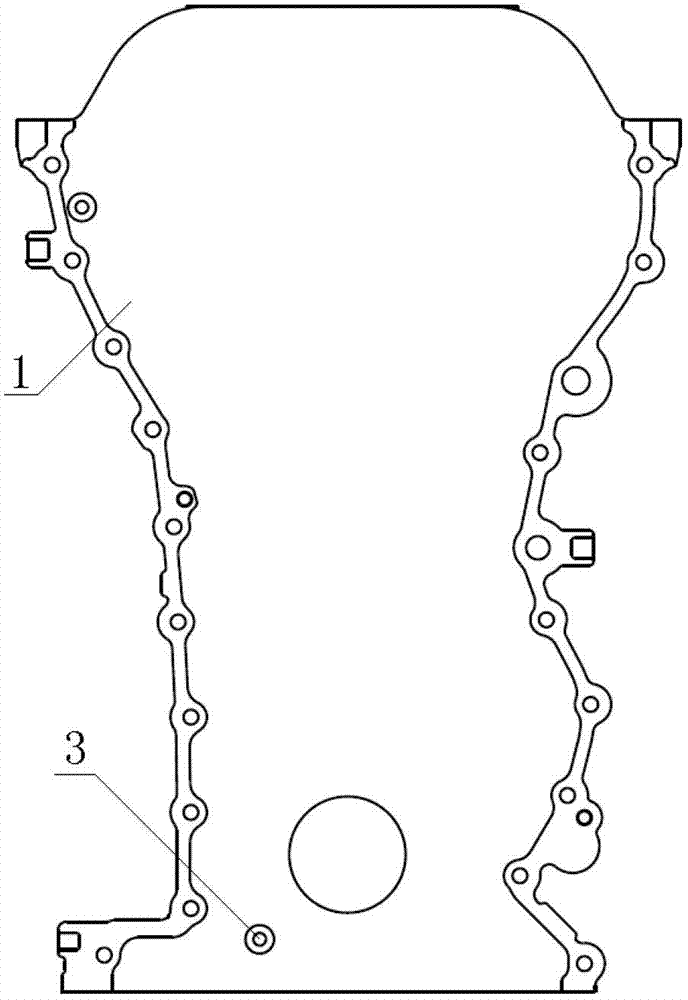

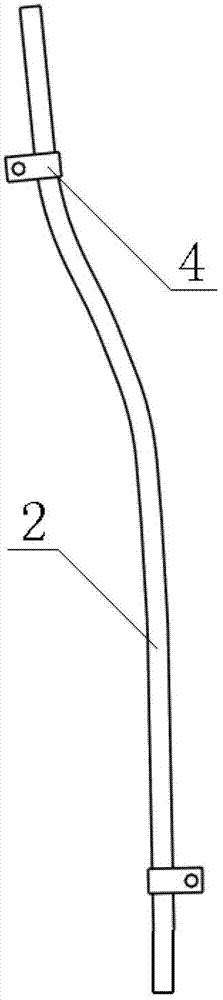

[0018] Depend on Figure 1-3 Combining the shown structures, it can be seen that this kind of engine timing cover includes a timing cover body 1 and an oil dipstick tube 2 integrated with the timing cover body 1, and the timing cover body 1 is provided with an oil dipstick tube for installing an oil dipstick. The boss 3 of the tube 2, and the boss 3 is provided with a bolt hole, and the oil dipstick tube 2 is provided with a welding bracket 4 with a mounting hole, and the boss 3 and the welding bracket 4 are connected together by bolts; the welding bracket 4 has Two are respectively located at the two ends of the oil dipstick tube 2 , and there are two bosses 3 , which are arranged on the timing cover body 1 corresponding to the welding bracket 4 .

[0019] The surface of the boss 3 needs to be machined to confirm that it has good flatness, and the middle is punched and tapped. The position of the boss 3 needs to be arranged close to the side of the timing cover body 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com