Reciprocating moving part transient temperature detection device and installation method thereof

A reciprocating motion, transient temperature technology, used in measuring devices, thermometers, thermometers using directly heat-sensitive electrical/magnetic components, etc., can solve the problems of inability to install temperature sensors and difficult installation of temperature sensors, saving external Space, improve environmental adaptability, reduce the effect of self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0038]In order to thoroughly understand the embodiments of the present invention, the detailed structure will be set forth in the following description. Obviously, the practice of the embodiments of the invention is not limited to specific details familiar to those skilled in the art. Preferred embodiments of the present invention are described in detail below, however, the present invention may have other embodiments besides these detailed descriptions.

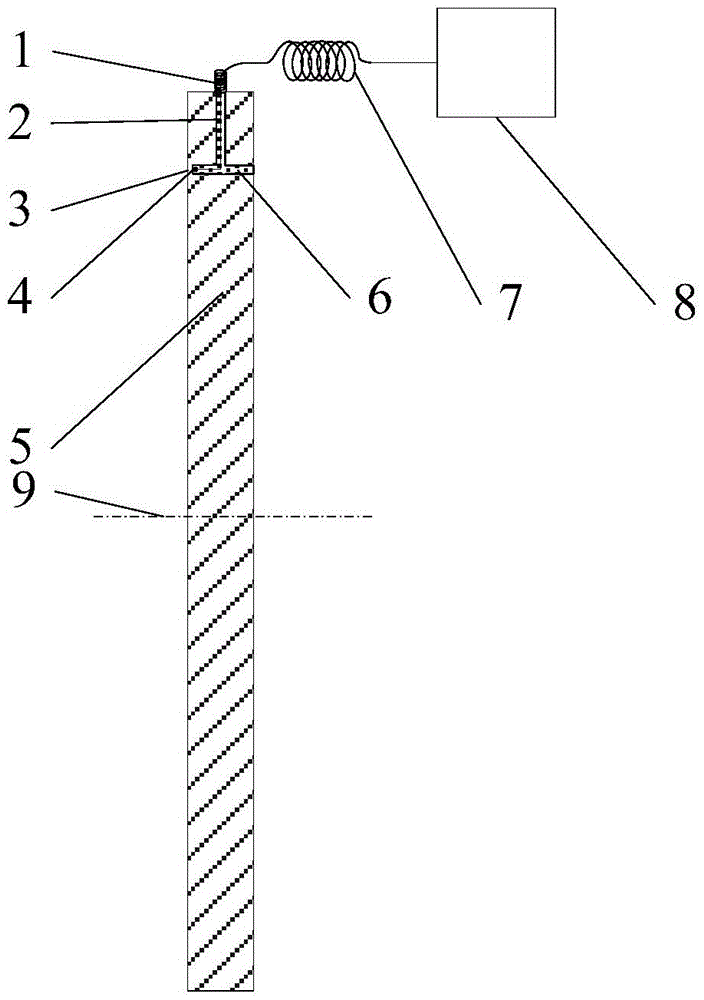

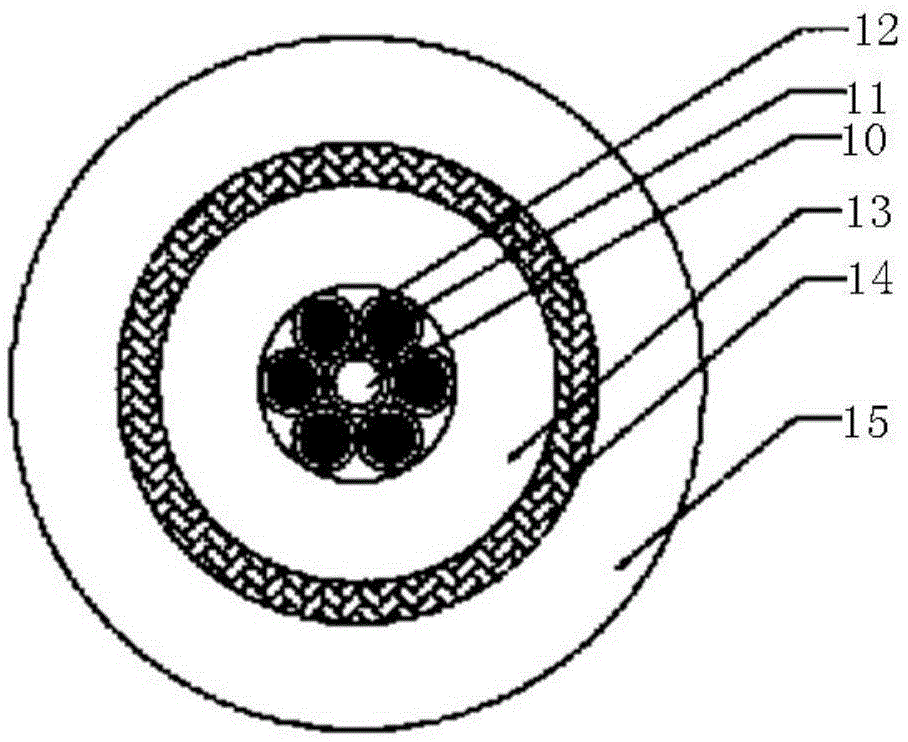

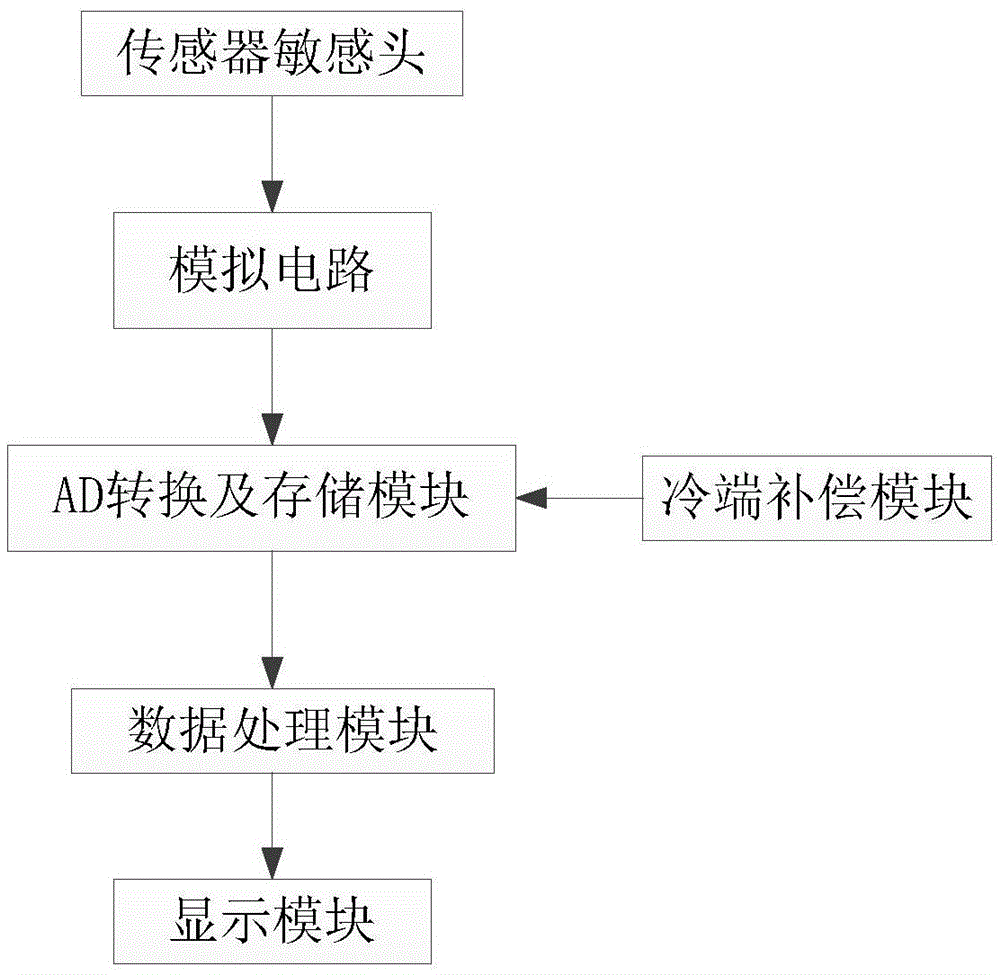

[0039] The structure of the transient temperature detection device for reciprocating parts provided in this embodiment is as follows: figure 1 As shown: the reciprocating part 5 is a steel sheet structure, and the reciprocating part 5 makes left and right reciprocating circular arc movements around the rotation center 9; in order to measure the temperature of the reci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com