Method for adjusting route reciprocating clearance

A technology of clearance and stroke, applied to belts/chains/gears, mechanical equipment, transmission devices, etc., can solve the problems of difficult installation and maintenance, high cost, complex structure, etc., and achieve the effect of convenient installation and maintenance, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

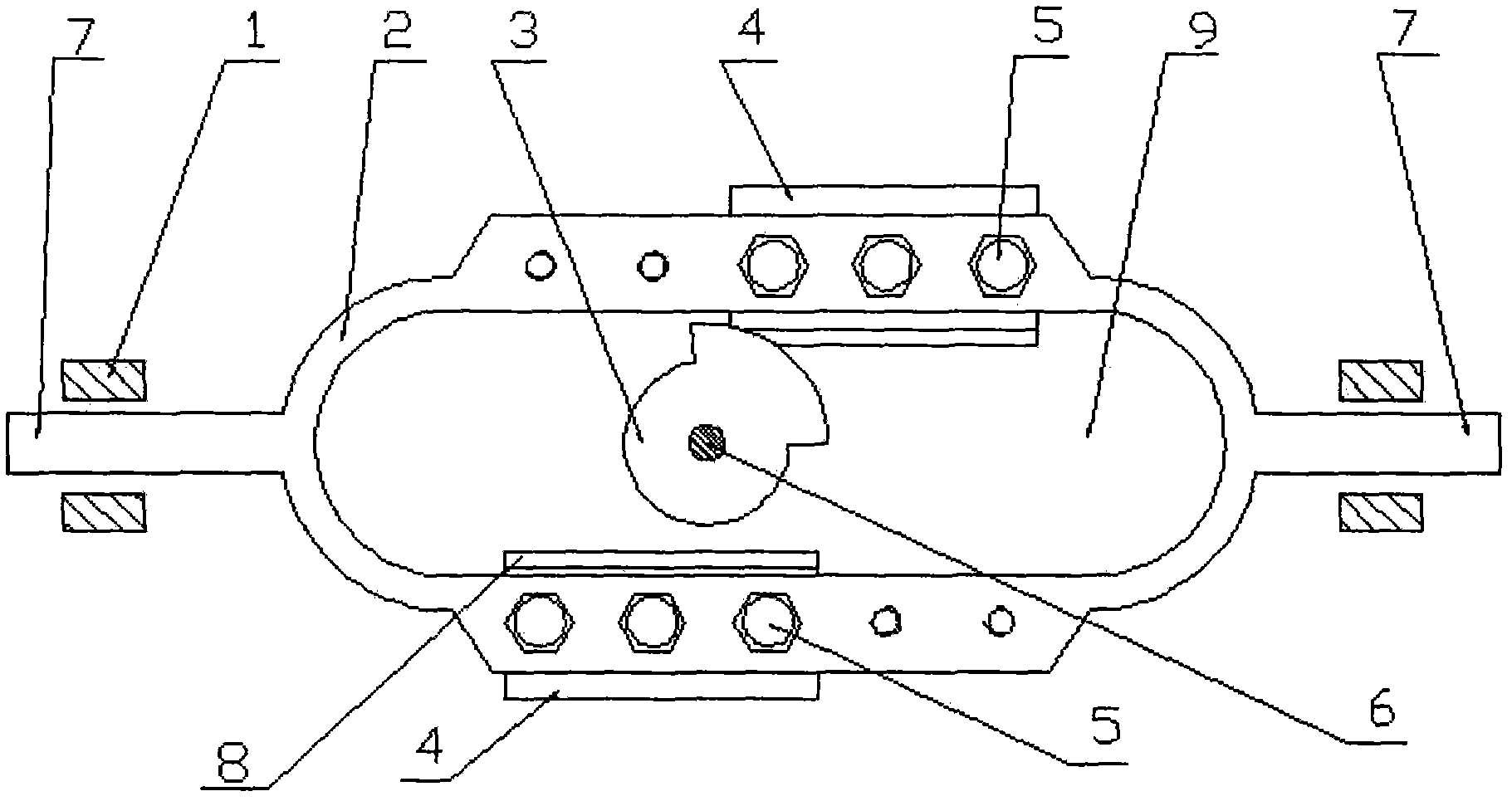

[0008] The middle part of the rack (2) is made into a rectangular frame. At the two ends of the rectangular frame of the rack (2), the sliding shafts (7) are symmetrically installed and fixed, and the rack (2) slides symmetrically through its two ends The shaft (7) is installed in the sliding bearing (1), and the frame (2) has a degree of freedom to move relative to the sliding bearing (1). The upper and lower sides of the rectangular frame of the frame (2) are provided with long slots communicating inside and outside. (8) The rack (4) is composed of the same two pieces. Install and fix the rack (4) with bolts (5) in the long slots (8) on the upper and lower sides of the rectangular frame of the frame (2); The toothless gear (3) is installed and fixed on the middle part of the rectangular frame of the frame (2) through a central shaft (6).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com