Measuring and self-calibration method for xenon lamp light source

A self-calibration, xenon lamp technology, applied in the direction of testing optical properties, can solve the problems of no production, long calibration cycle, expensive calibration costs, etc., to achieve the effect of simplified calibration process, accurate calibration and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Before using a xenon lamp light source measurement and self-calibration method of the present invention, according to the calibration requirements, after the entire measurement system is connected, the standard energy lamp is used to calibrate the entire measurement system to ensure that the benchmarks of each measurement result are consistent. and the self-calibration method includes the following steps:

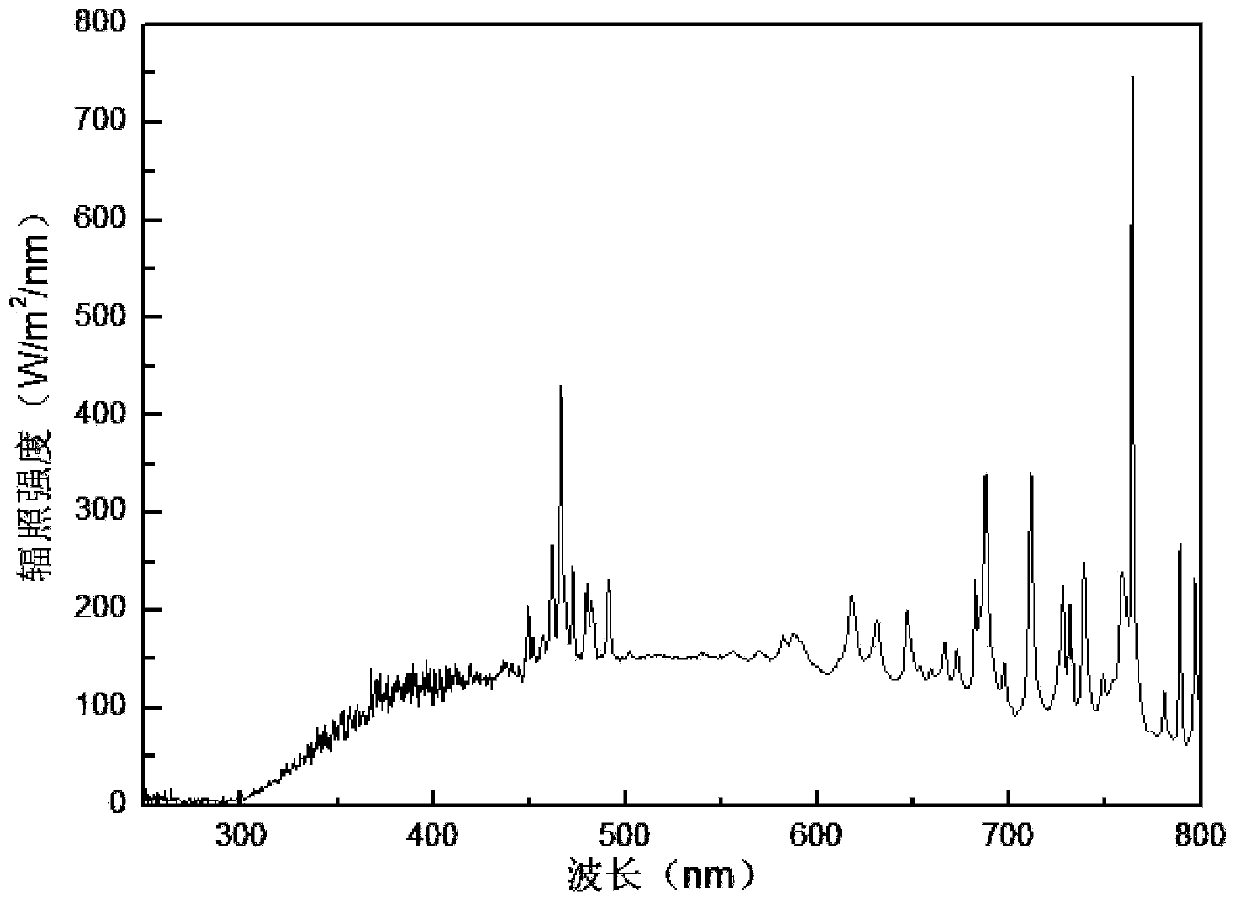

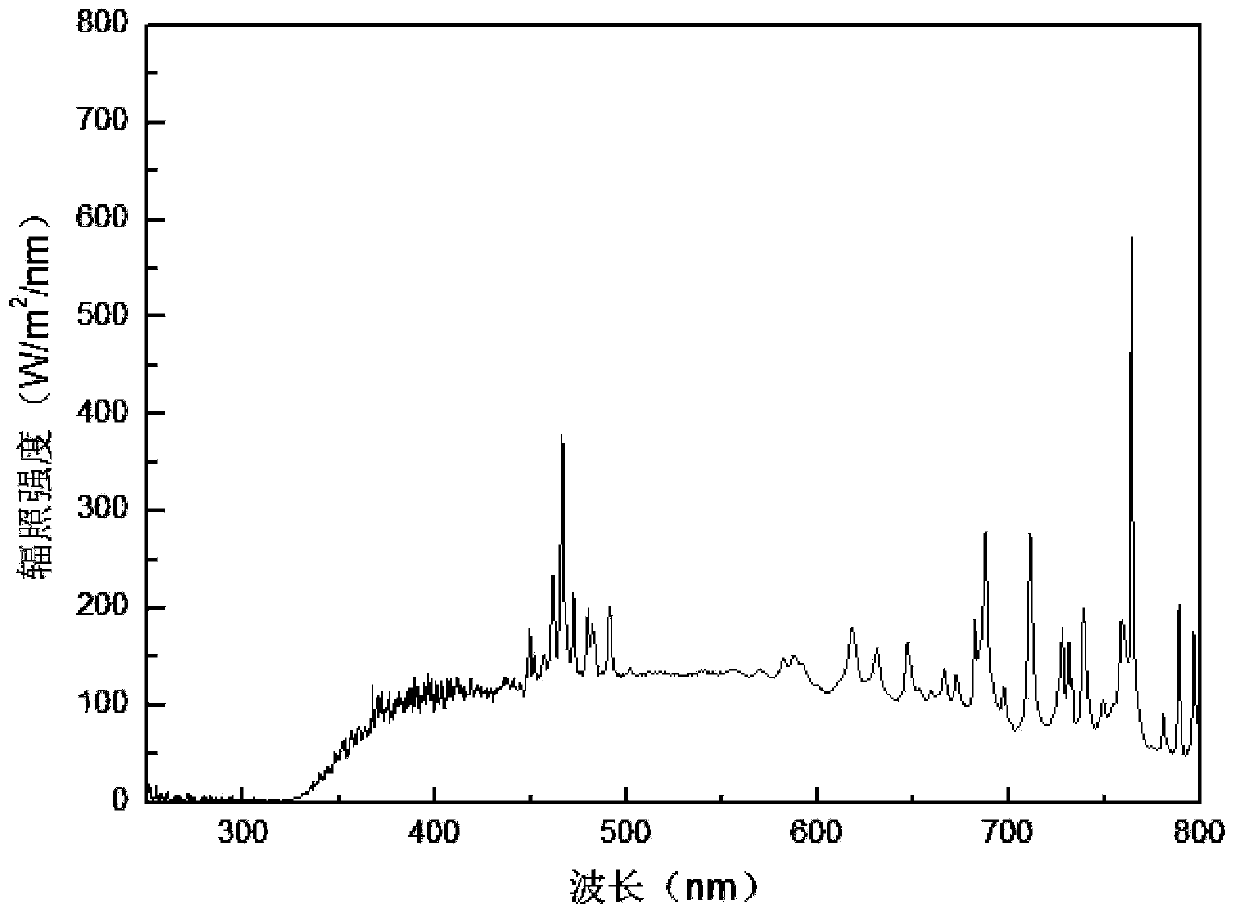

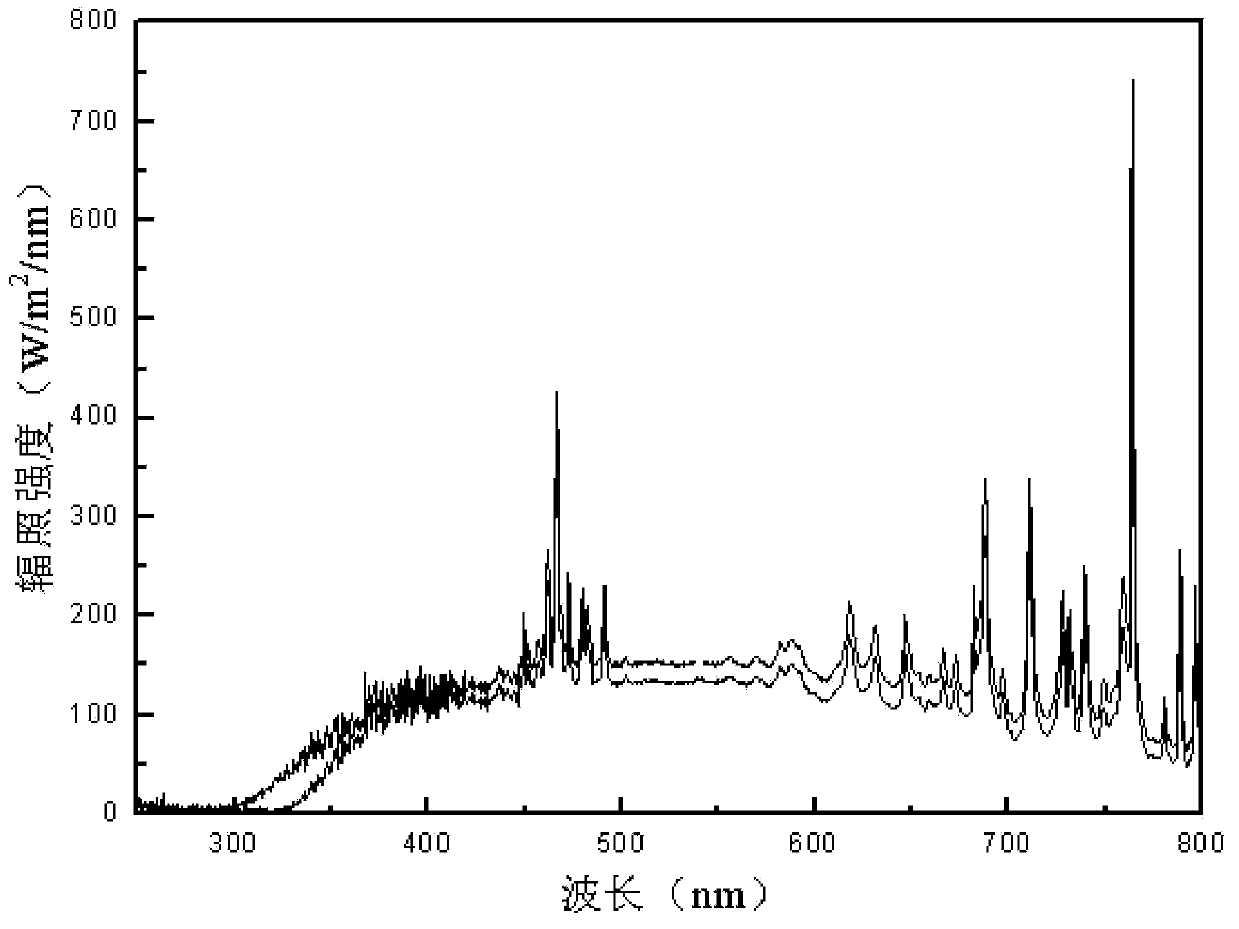

[0054] (1) Use the measurement system to measure the new light tube of the xenon lamp. The specific method for measuring the new light tube of the xenon lamp is: use a fiber optic spectrometer and an optical fiber with a cosine corrector. When the new light tube of the xenon lamp is installed vertically, the optical fiber Both the probe and the light sensor that comes with the xenon lamp are located on the inner wall of the xenon lamp cavity, and are at the same horizontal position. The new light tube of the xenon lamp is measured through the optical fiber and fiber o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com