Large drift diameter built-in high-pressure sampling valve

A large-diameter, sampling valve technology, used in sampling devices and other directions, to achieve stable and reliable action, broad application prospects, and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

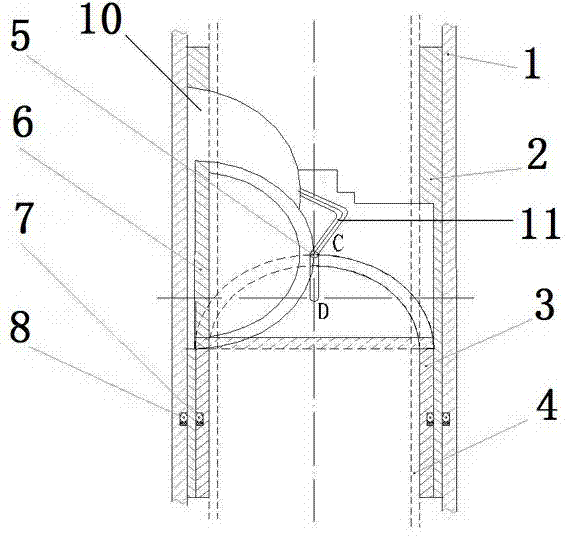

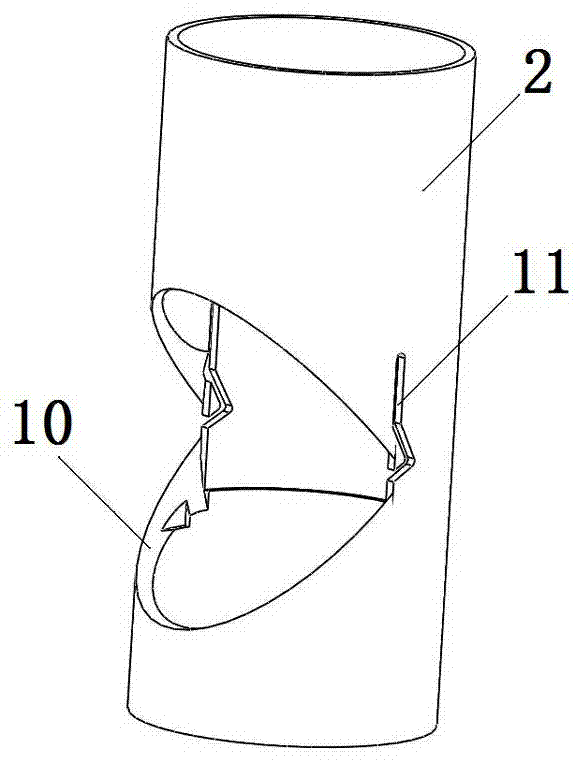

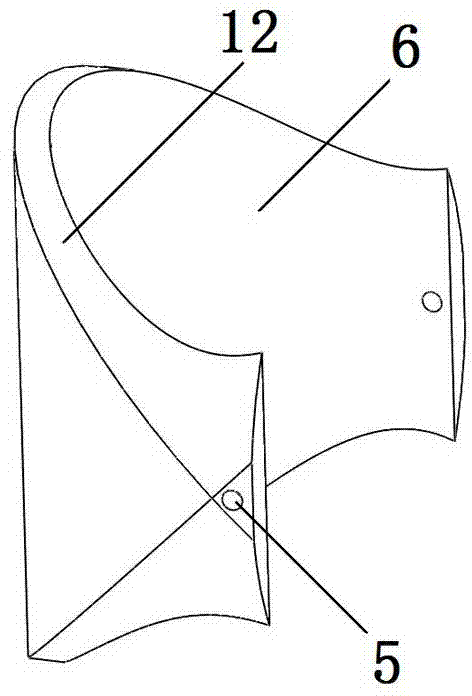

[0017] The present invention is installed in the drill sleeve of the seabed in-situ drilling equipment, that is, the valve body 2 is located in the drill sleeve sampling tool body 1, and there is a sealing ring 8 between the two. When in the original position: the sealing valve seat 3 is sleeved in the valve body 2, and there is a sealing ring 7 between them. The sealing sliding plate 6 is installed into the valve body 2 from the opening 10 , and the small shafts 5 at both ends thereof are located at the penetration point C in the chute 11 . Then the sampling core pipe 4 is housed in the space jointly formed by the valve body 2, the sealing valve seat 3 and the sealing slide plate 6.

[0018] In the present invention, the sealing slide plate 6 is the most critical part, which plays the role of closing and penetrating, and is a switch part. In the above-mentioned initial state, the sealing slide plate 6 is in a state of standing sideways, the purpose is to make room for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com