Seeding monitoring system of corn precision seeder

A monitoring system and precision seeding machine technology, applied in general control systems, control/regulation systems, seeder parts, etc., can solve problems such as difficulty in normal operation of the seeding monitoring system, inaccurate measurement accuracy, and loss of agricultural production, etc., to achieve Improve the quality of seeding operations, strong anti-interference, and improve the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

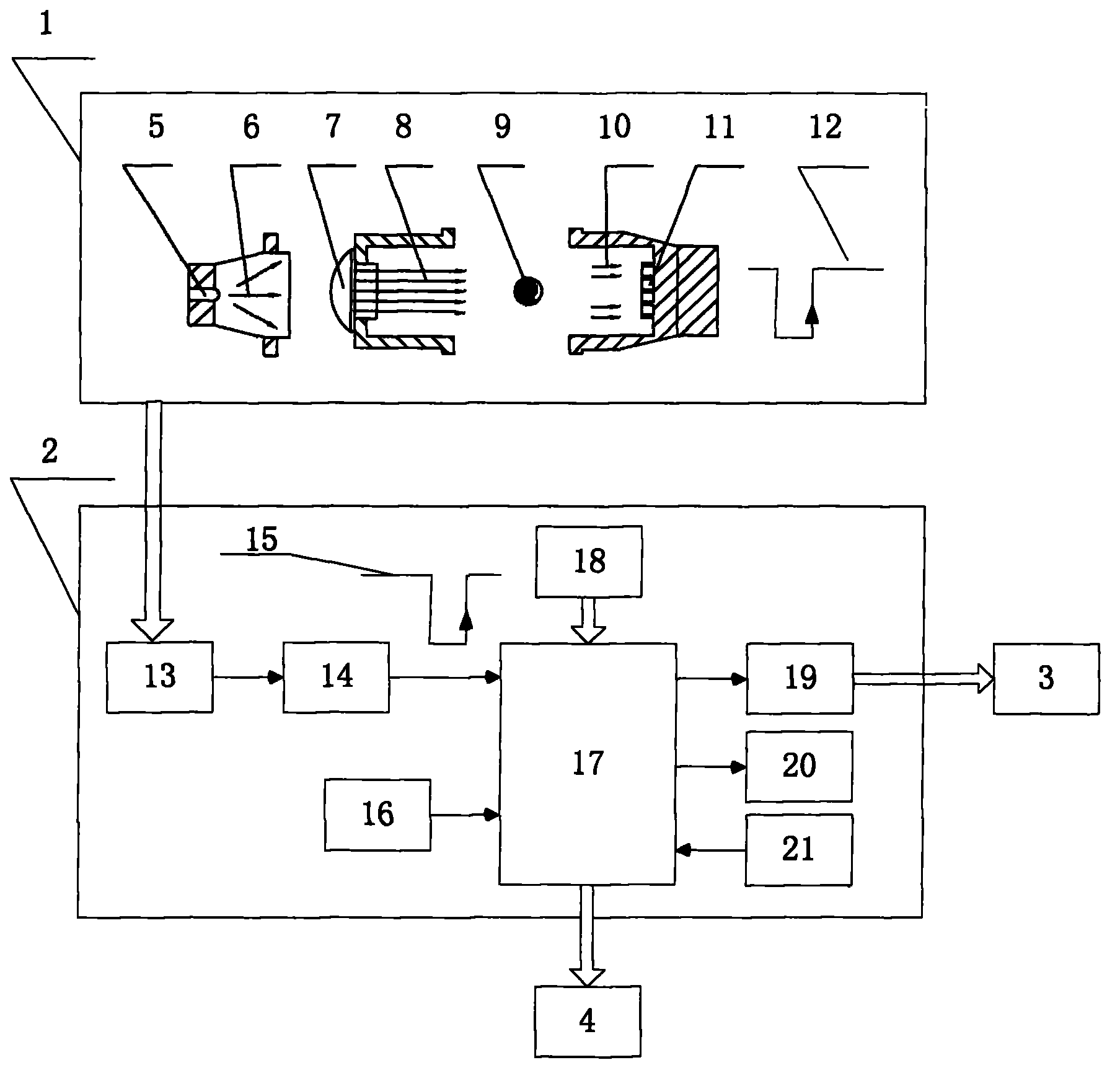

[0020] The seeding monitoring system of the corn precision seeder is characterized in that the equipment required by the system and the implementation steps are as follows:

[0021] Required equipment: The equipment required by the present invention is mainly composed of 4 parts: sensor detection part 1, single-chip microcomputer measurement and control part 2, sound and light alarm part 3 and indicator box unit 4. The sensor detecting part 1 is composed of a laser emitting diode 5, a convex lens 7 and a laser receiving part 11. The laser receiving part 11 is formed by connecting four laser receiving diodes in series, and the distance between every two laser diodes is 3mm. The laser emitting diode 5 emits a scattered micropower laser signal 6 at an angle of 60 degrees, which becomes a parallel beam 8 after passing through the convex lens 7, and is received by the laser receiving part 11. The single-chip microcomputer measurement and control part 2 is composed of LM358 amplifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com