Starting control method and control device of direct-current variable frequency air-conditioning compressor

An air-conditioning compressor, DC frequency conversion technology, applied in the direction of the starting device, etc., can solve the problems of permanent magnet demagnetization, demagnetization, and unsatisfactory effects, and achieve the effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

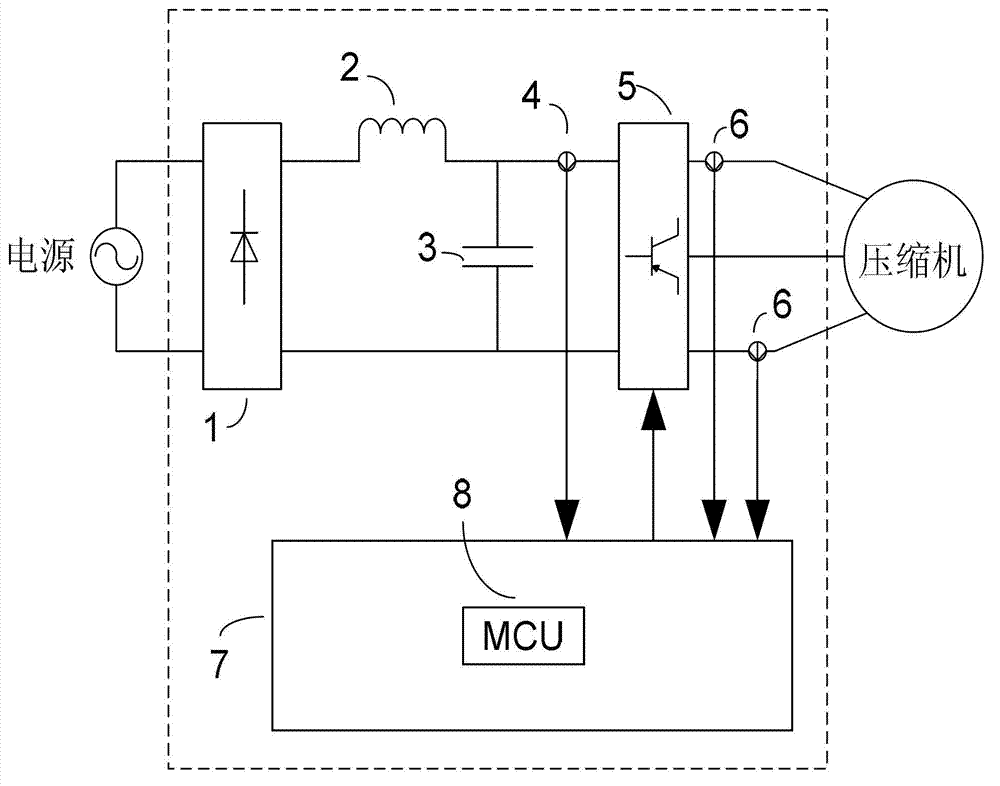

[0046] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

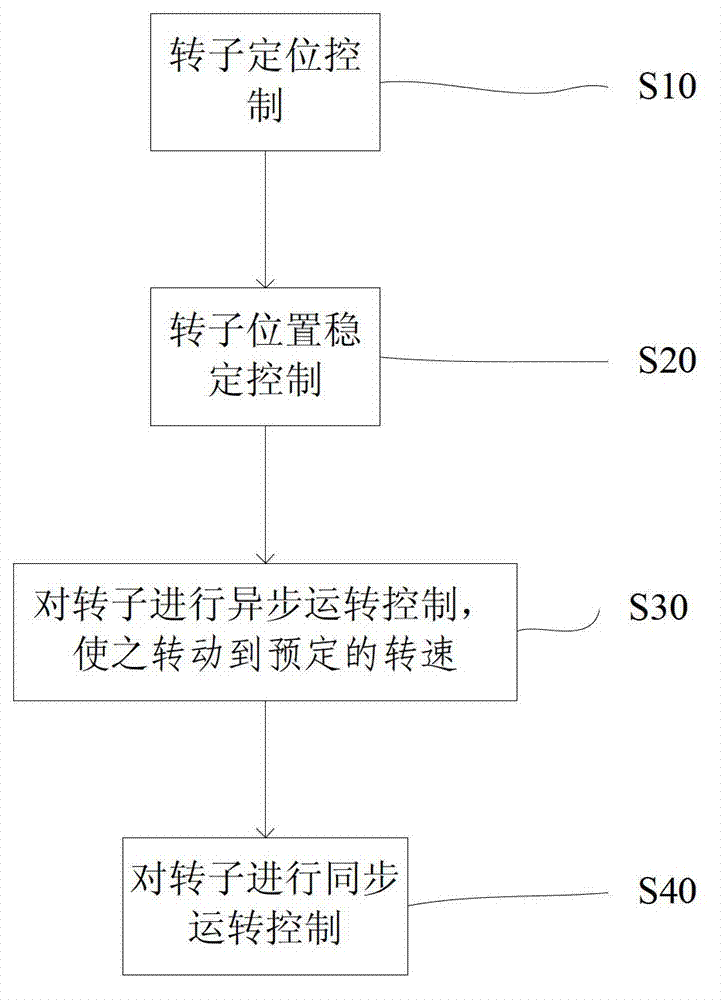

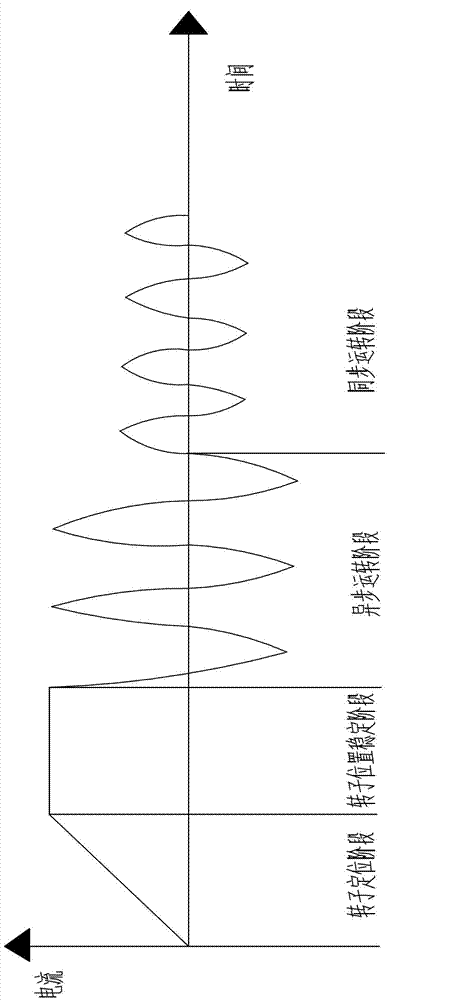

[0047] figure 1 A control flow diagram of an embodiment provided by the present invention, figure 2 A time-current relationship diagram of an embodiment provided by the present invention. From figure 2 It can be seen that in this embodiment, the start-up process is divided into four stages: rotor positioning stage, rotor position stabilization stage, asynchronous operation stage, and synchronous operation stage, that is, the four steps mentioned below.

[0048] The start-up process of the DC inverter air conditioner compressor is divided into the following four steps:

[0049] Step S10: The controller performs positioning control on the rotor of the compressor, so that the rotor rotates to a predetermined position. The compressor is in a static state before starting, but the position of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com