Method for preparing boron-modified commercially pure aluminum with high strength and conductivity

A technology of industrial pure aluminum and boron modification, applied in the preparation of highly conductive boron modified industrial pure aluminum, high strength field, can solve the problems of complex forming process, alloy element pollution, low mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

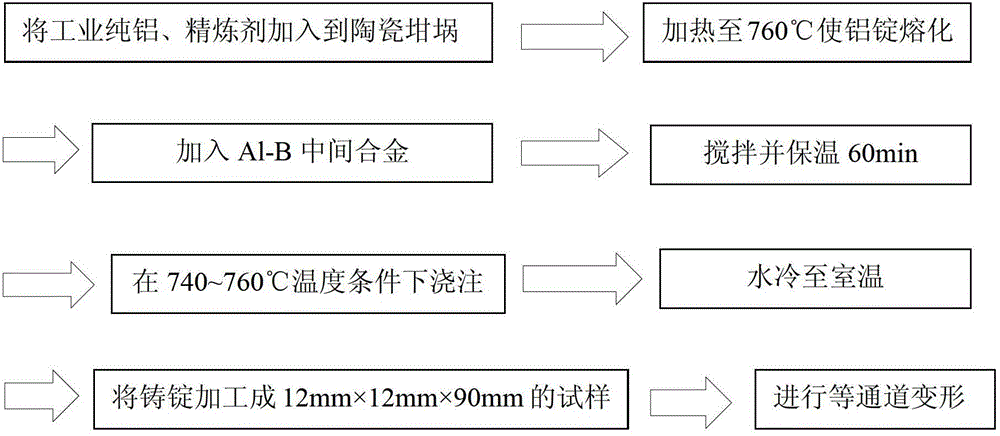

[0020] Process such as figure 1 , put industrial pure aluminum and refining agent into the ceramic crucible, put it into the pit furnace and heat it to 760°C to melt it, and then press the prepared aluminum-boron master alloy into the molten aluminum to make the boron element The content accounts for 0.1% of the total weight of the melt. After stirring, the temperature is raised to 760 ° C, and the temperature is kept for 60 minutes.

[0021] The aluminum ingot is processed into a sample of 12mm×12mm×90mm, the surface of the sample is coated with lubricant, and the deformation of 1, 2, 4 and 8 passes is carried out. The inner angle of the mold is Φ110°, and the deformation of each pass is uniform Without rotating the sample, the deformation speed is 12mm / min.

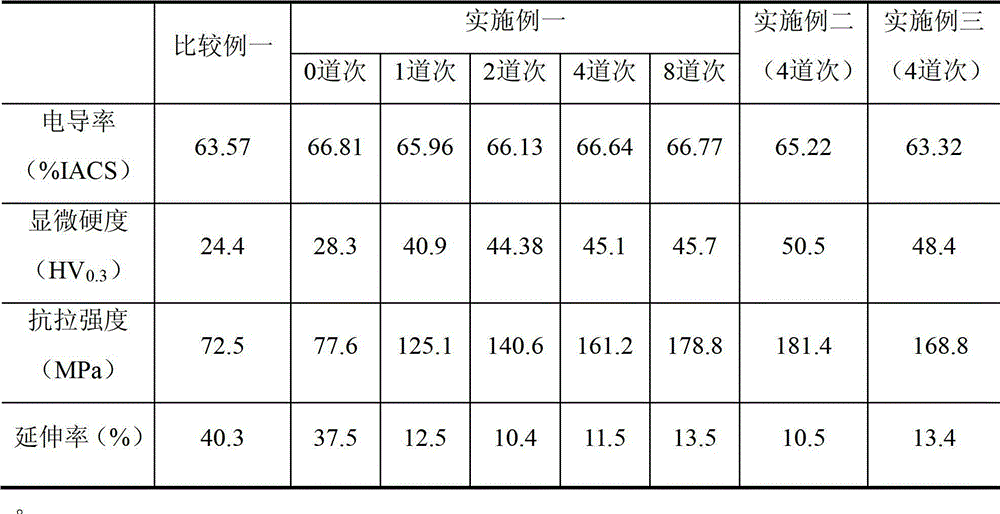

[0022] Roughly grind, finely grind, and polish the equal-channel deformed sample, and use an eddy current conductivity meter to test the conductivity. The relative conductivity (room temperature) of the aluminum sampl...

Embodiment 2

[0024] Put industrial pure aluminum and refining agent into the ceramic crucible, put it into the pit furnace and heat it to 760°C to melt it, then press the prepared aluminum-boron master alloy into the molten aluminum to make the content of boron element Accounting for 0.02% of the total weight of the melt, stir, raise the temperature to 740°C, and after standing for 5 minutes, pour the molten aluminum into the iron mold, demould, and water-cool to room temperature.

[0025] The aluminum ingot is processed into a sample of 12mm×12mm×90mm, the surface of the sample is coated with a lubricant, and 4 passes of equal-channel deformation are carried out. The inner angle of the mold is 90°, and the sample is not rotated in each pass of deformation. Speed 12mm / min.

[0026] Roughly grind, finely grind, and polish the equal-channel deformed sample, and use an eddy current conductivity meter to test the conductivity. The relative conductivity (room temperature) of the aluminum sam...

Embodiment 3

[0028] Put industrial pure aluminum and refining agent into the ceramic crucible, put it into the pit furnace and heat it to 760°C to melt it, then press the prepared aluminum-boron master alloy into the molten aluminum to make the content of boron element Accounting for 0.2% of the total weight of the melt, stir, raise the temperature to 760°C, and keep it for 60 minutes, then pour the molten aluminum into the iron mold, demould, and water-cool to room temperature.

[0029] The aluminum ingot is processed into a sample of 12mm×12mm×90mm, the surface of the sample is coated with a lubricant, and 4 passes of equal channel deformation are carried out. The inner angle of the mold is 120°, and the sample is not rotated in each pass of deformation. Speed 12mm / min.

[0030] Roughly grind, finely grind, and polish the equal-channel deformed sample, and use an eddy current conductivity meter to test the conductivity. The relative conductivity (room temperature) of the aluminum samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com