Device used for forming SiN film on substrate

A substrate and thin film technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of high equipment input cost, and achieve the effect of reducing high cost, low input cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

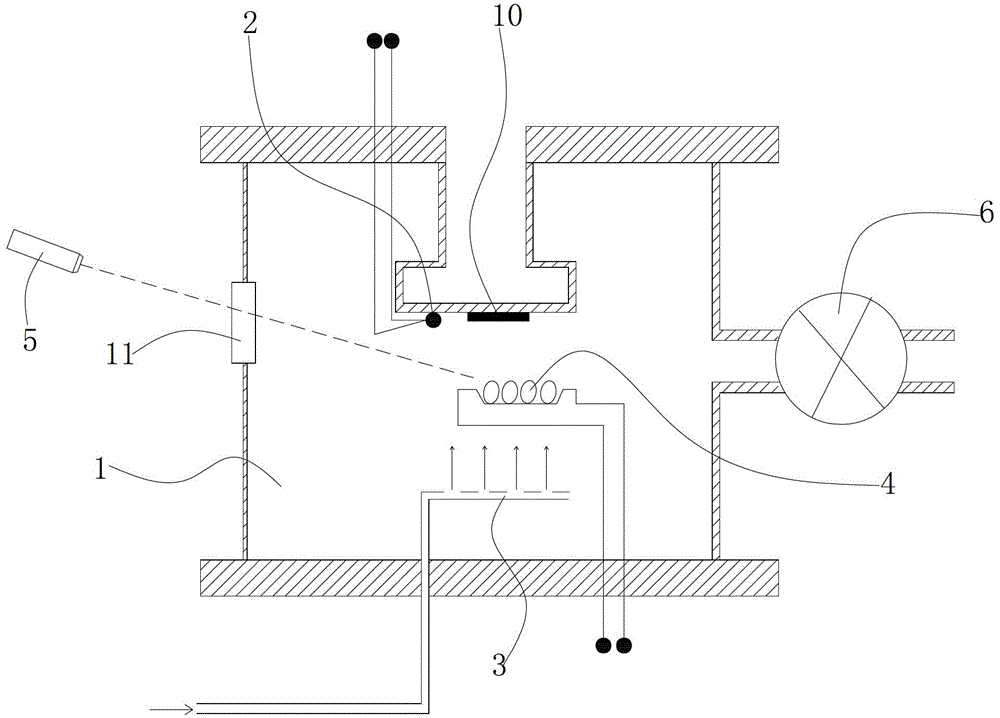

[0020] Such as figure 1 As shown, a device for forming a SiN thin film on a substrate includes a vacuum reaction chamber 1, a substrate holder, a substrate temperature measurement module 2, a gas introduction module 3, a heating catalyst 4, a Infrared thermal measuring instrument 5, and an exhaust system.

[0021] The substrate frame is arranged in the vacuum reaction chamber 1 for placing the substrate 10 .

[0022] The substrate temperature measurement module 2 is arranged on the substrate frame to measure the temperature of the substrate 10, which is a thermocouple, and can send the detected thermal electromotive force signal representing the substrate temperature to an external electrical instrument, The electrical instrument displays the temperature value of the substrate according to the thermal electromotive force signal. In this embodiment, the temperature of the substrate 10 is between 230°C and 380°C, preferably 300°C.

[0023] The gas introduction module 3, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com