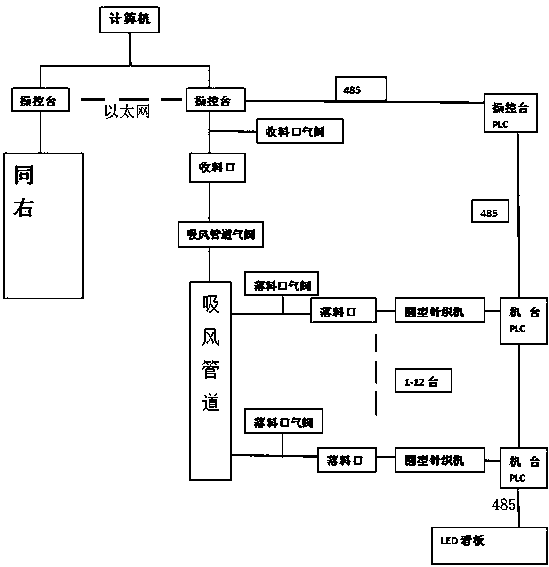

Logistic control system used for round knitting machine

A technology of circular knitting machine and control system, which is applied in knitting, weft knitting, textile and paper making, etc., can solve the problems of waste of resources, low production efficiency, and difficulty in realizing automatic material collection, so as to save costs and improve production. Efficiency, the effect of reducing the number of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

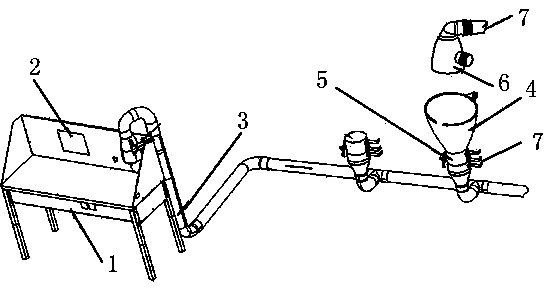

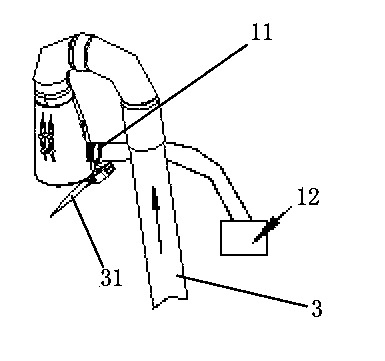

[0016] See attached picture. This embodiment is a set of control systems, including a console 1, 12 machines, a suction duct 3 and a material receiving port. LED display screen and touch screen 2 are arranged on the control console 1, and a through hole 11 is arranged on the console 1; There is a machine collection bag 4 directly below the mouth 6, and there is a mounting hole on the suction duct 3, and a collection port 5 of the suction duct is installed in the installation hole, and the bottom of the machine collection bag 4 has no bottom and is in line with the westerly wind. The collection port 5 of the pipeline is connected, and one end of the suction duct is a material receiving port, the material receiving port is open and has a cover plate 31 at the outlet, and the material receiving port is directly above the operating table 1 , There is a hole on the side wall of the opening of the suction duct, and a suction fan 12 passes through the through hole 11 on the console ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com