Water injection drilling and blasting method for unloading stress of structural strong rock burst area of horizontal structural surface

A horizontally structured and structural technology, applied in blasting and other directions, can solve problems such as being in a blank state, and achieve the effects of improving construction safety, ensuring the progress of the tunnel, and eliminating energy accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

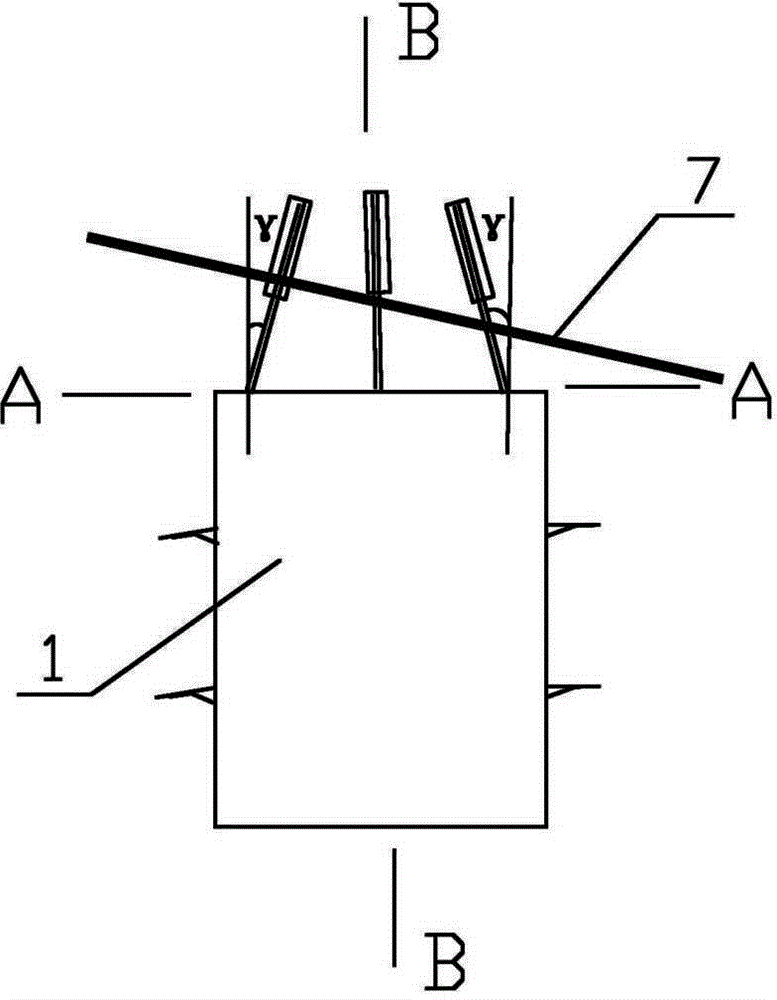

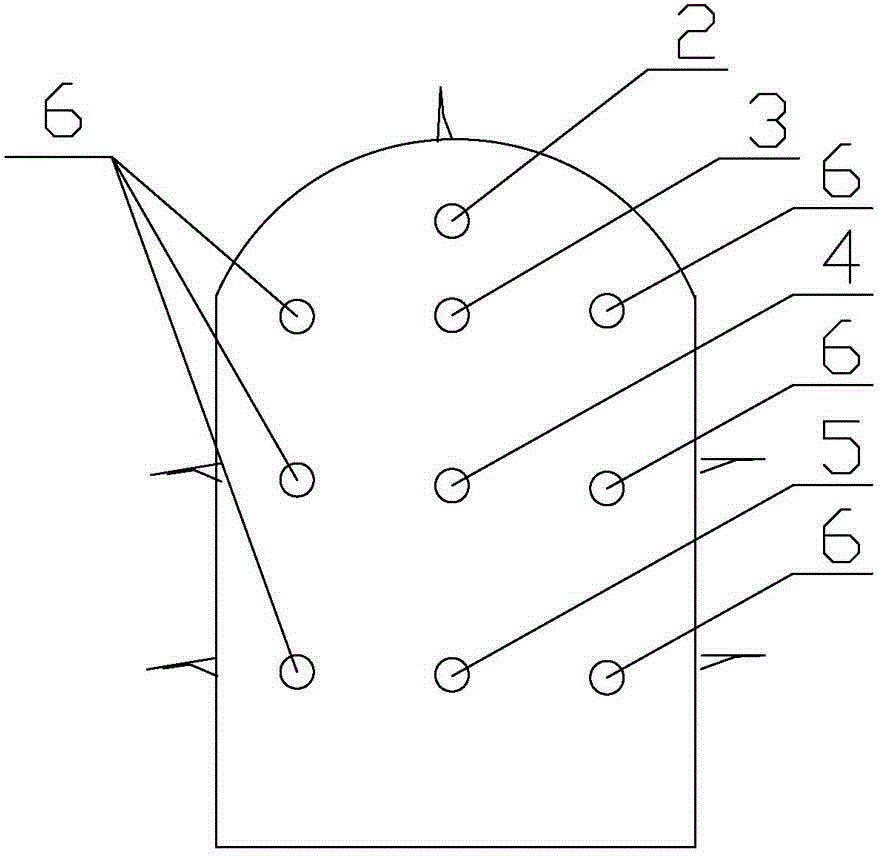

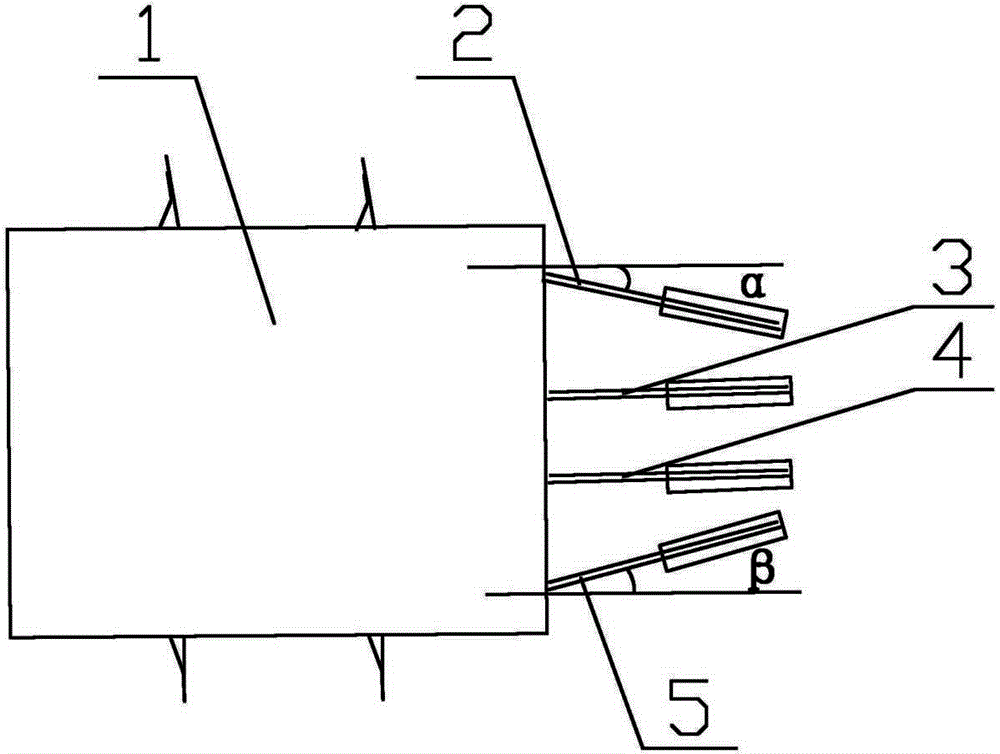

[0018] Such as Figure 1-Figure 3 As shown, this embodiment adopts a series of orderly working methods such as drilling, water injection, and rationally arranging blast holes in the stress concentration area, and adopts a short-footage, multi-cycle excavation method. The construction steps are as follows:

[0019] a. Drill a group of evenly and symmetrically arranged blast holes on the excavation surface of tunnel 1 (its cross section is in the shape of a city gate), and ensure that each blast hole is located in the stress concentration area, and the hole depth should reach or pass through The stress concentration area is the principle; the number of blasting holes, the size of the holes, the water injection pressure and the amount of charge are based on the principle of weakening the rock mass to the greatest extent and not excessively damaging the rock mass to cause an increase in the support workload. At the same time, the potential rockburst intensity and the site Support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com