Sand and dust abrasion test device and test method for train motor insulation structure

A sand and dust abrasion test and insulation structure technology, applied in the direction of testing wear resistance, etc., can solve the problems that the sand and dust abrasion resistance of the insulation structure cannot be comprehensively expressed, and multiple variables cannot be adjusted at the same time, and the temperature is adjustable and convenient. The effect of taking out the workpiece and adjusting the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

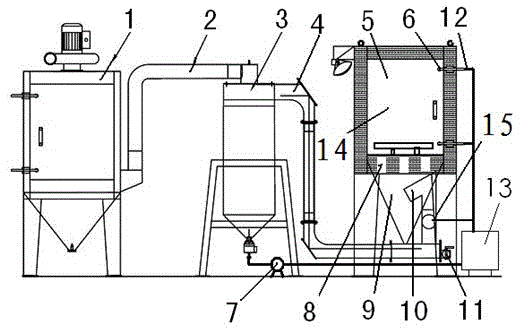

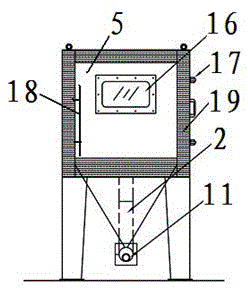

[0036] A sand and dust abrasion test device with an insulating structure is used to test the sand and dust abrasion resistance of the insulating structure in the train motor: the test device includes four parts: a sand blasting pressurization device 13, a working box 5, a dust removal device 3 and a control system. .

[0037] As a further embodiment of the present invention, the air source interface of the sandblasting and pressurizing device 13 is equipped with a dryer to prevent high-pressure wind and water gas from entering and causing sand and dust nodules to cause pipeline blockage. It is also equipped with a pressure regulating valve and a pressure gauge, which can realize The pressure in the sandblasting pipeline 12 is adjustable, and the sand outlet is equipped with a valve for adjusting the amount of sandblasting.

[0038] As a further embodiment of the present invention, the work box 3 is equipped with a spray gun rack for fixing the spray gun 6 and can realize the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com