Optical cable connector for device access and optical cable installing and sealing component thereof

A technology for optical cable connectors and sealing components, applied in the coupling of optical waveguides, fiber mechanical structures, etc., can solve the problems of high cost, complicated sealing operation methods, unsuitable for efficient and fast installation, etc., to achieve fast sealing installation and simple structure , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

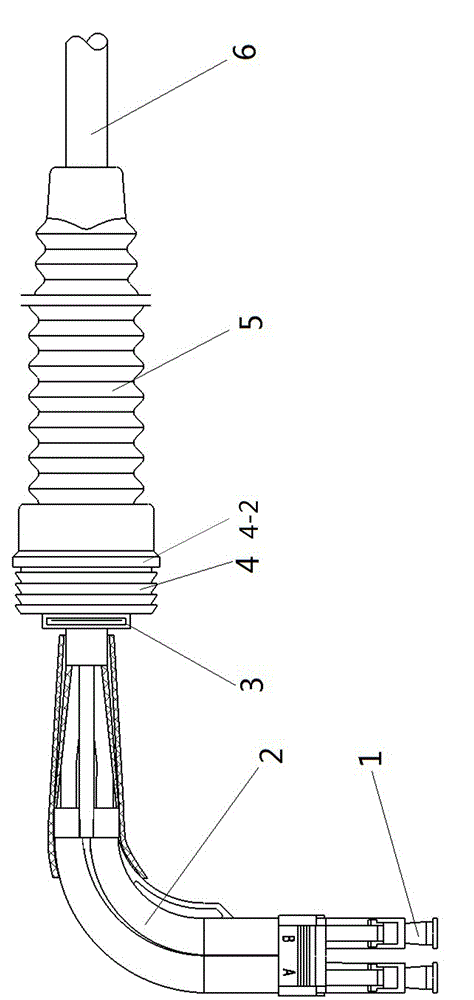

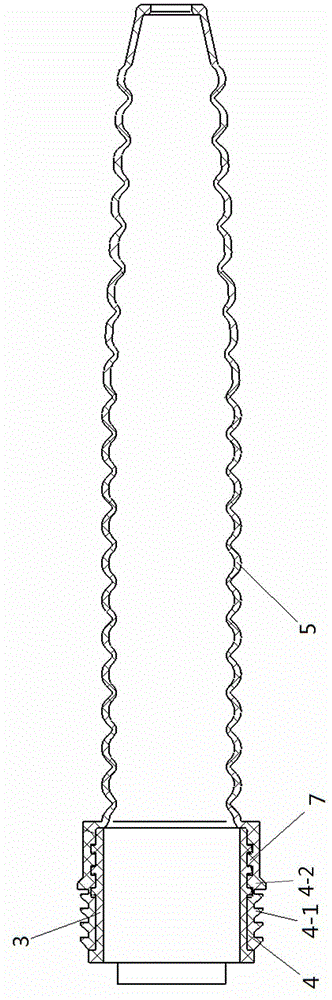

[0021] Implementation example of optical cable connector for equipment access Figure 1~2 Shown: It includes an optical cable 6, a DLC plug 1 connected to the rear end of the optical cable 6, and an optical cable installation sealing assembly arranged in front of the DLC plug. The optical cable installation and sealing assembly includes a supporting sleeve 3, an optical cable elbow sheath 2, and a sealing sleeve 4 made of flexible material and sleeved on the supporting sleeve 3 and axially restricted by an axial limiting structure. In this embodiment The middle sealing sleeve is a rubber sleeve, and the back end of the sealing sleeve is integrally provided with a corrugated tube 5 for protecting the optical cable. The corrugated tube, the optical cable elbow sheath 2 and the supporting sleeve all have inner holes for the optical cable 6 to pass through, and the routing directions of the inner holes of the optical cable elbow sheath 2 are perpendicular to each other. The rear e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com