A liquid crystal display module and a liquid crystal display device

A technology of liquid crystal display module and liquid crystal display device, applied in nonlinear optics, instruments, optics, etc., can solve the problem that the frame cannot be further narrowed, and achieve the effect of simple structure and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

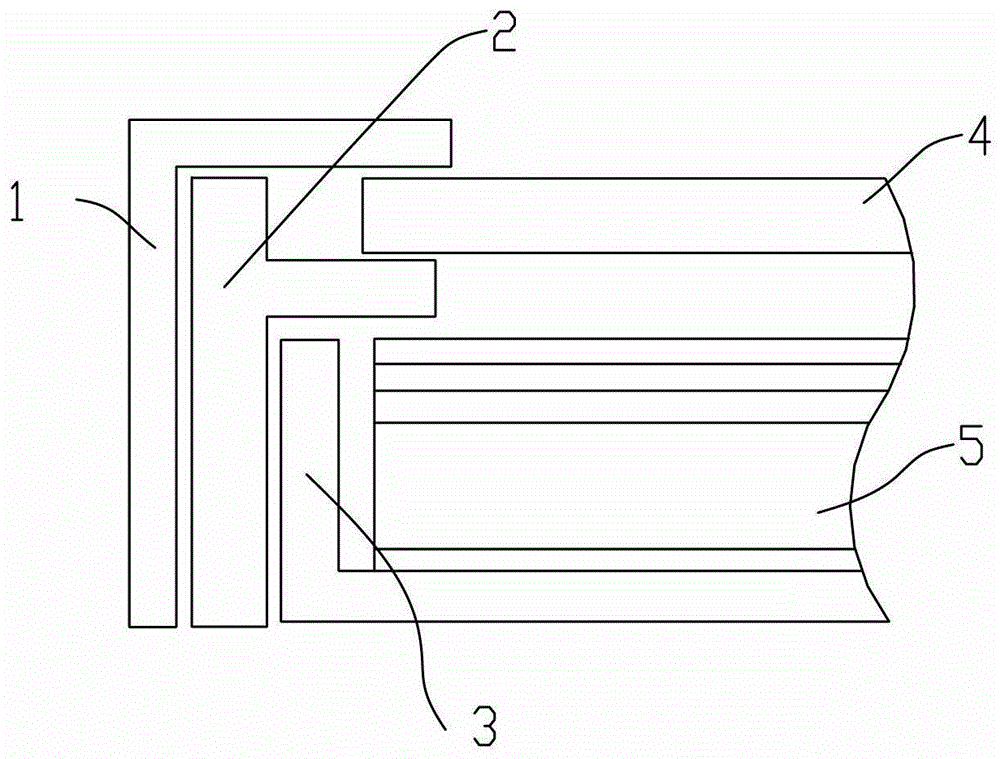

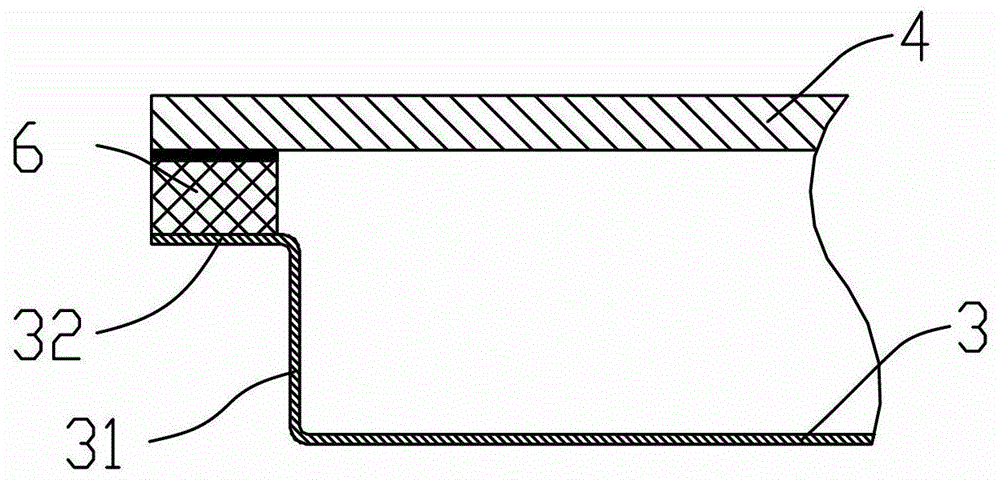

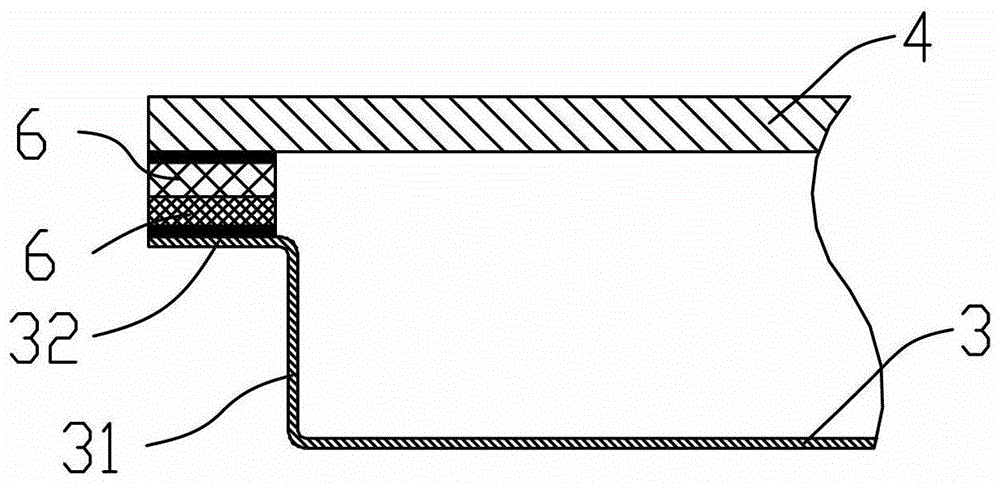

[0022] The invention discloses a liquid crystal display device including a liquid crystal display module, as the first embodiment of the liquid crystal display module of the invention, such as figure 2 As shown, a liquid crystal display panel 4 and a back plate 3 are included, and the liquid crystal display panel 4 and the back plate 3 are fixed by adsorption by a magnet 6.

[0023] In this embodiment, a magnet 6 is fixed on the back of the liquid crystal display panel 4, and the back plate 3 is connected to the liquid crystal display panel 4 from the back of the liquid crystal display panel 4. The specific method can be to paste the magnet 6 on the liquid crystal display with glue. On the panel 4, the back plate 3 includes a side wall 31, and a horizontal wall 32 is provided on the upper edge of the side wall 31 of the back plate 3. The horizontal wall 32 can support the liquid crystal display panel 4 and increase the adsorption area of the magnet 6 , More reliable, specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com