Liquid crystal box forming structure and process method for carrying out liquid crystal perfusion by adopting same

A process method and technology of liquid crystal cells, which are applied in nonlinear optics, instruments, optics, etc., can solve the problems of inability to discharge air bubbles, defects in the use performance of liquid crystal cells, and easy generation of air bubbles during the filling process, and achieve the effect of ensuring performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

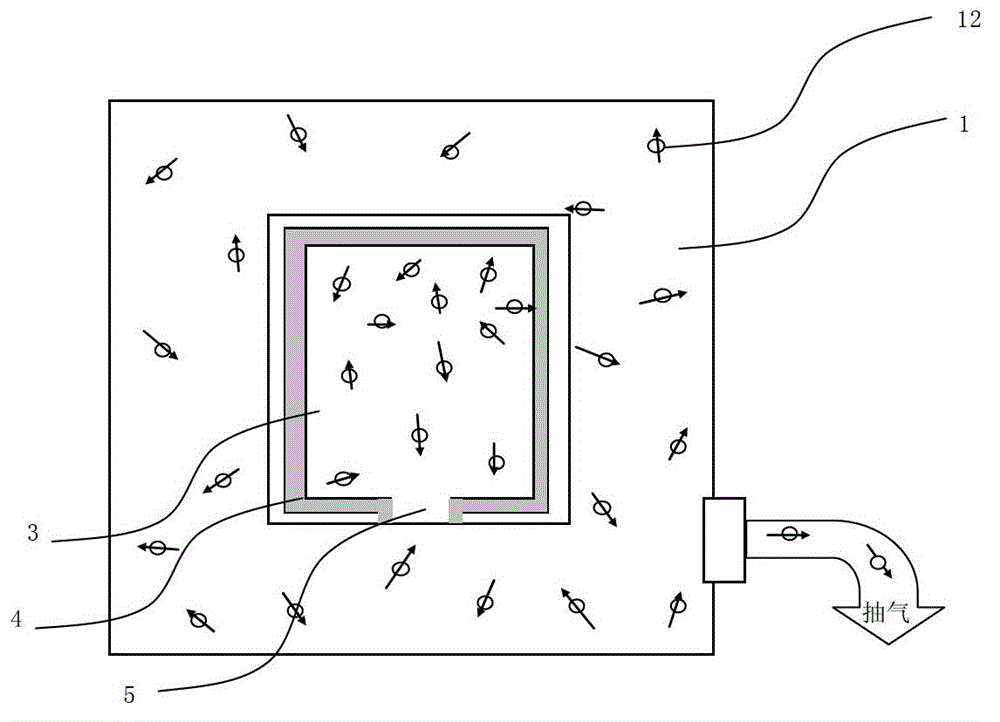

[0039] Such as image 3 As shown, when the vacuum chamber 1 of the filling machine in the prior art is evacuated, the vacuum degree of the chamber, that is, the initial vacuum of the filling can reach up to 1 Pa or even below, but the main body 3 of the liquid crystal cell (empty cell) to be filled It is difficult for the vacuum degree inside to reach this value, because the gas molecules 12 in the empty box need to be continuously diffused outside the box to achieve the air pressure balance inside and outside the box, that is, the depressurization process inside the box. Therefore, during the diffusion process, the Influenced by the thickness of the liquid crystal cell, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com