Overload relay based on wireless connection

A relay and wireless technology, applied in the field of overload relays based on wireless connection, can solve the problems of poor manufacturability and poor anti-vibration effect of overload relays, and improve the ability of anti-mold and salt spray, improve accuracy, and good electromagnetic shielding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

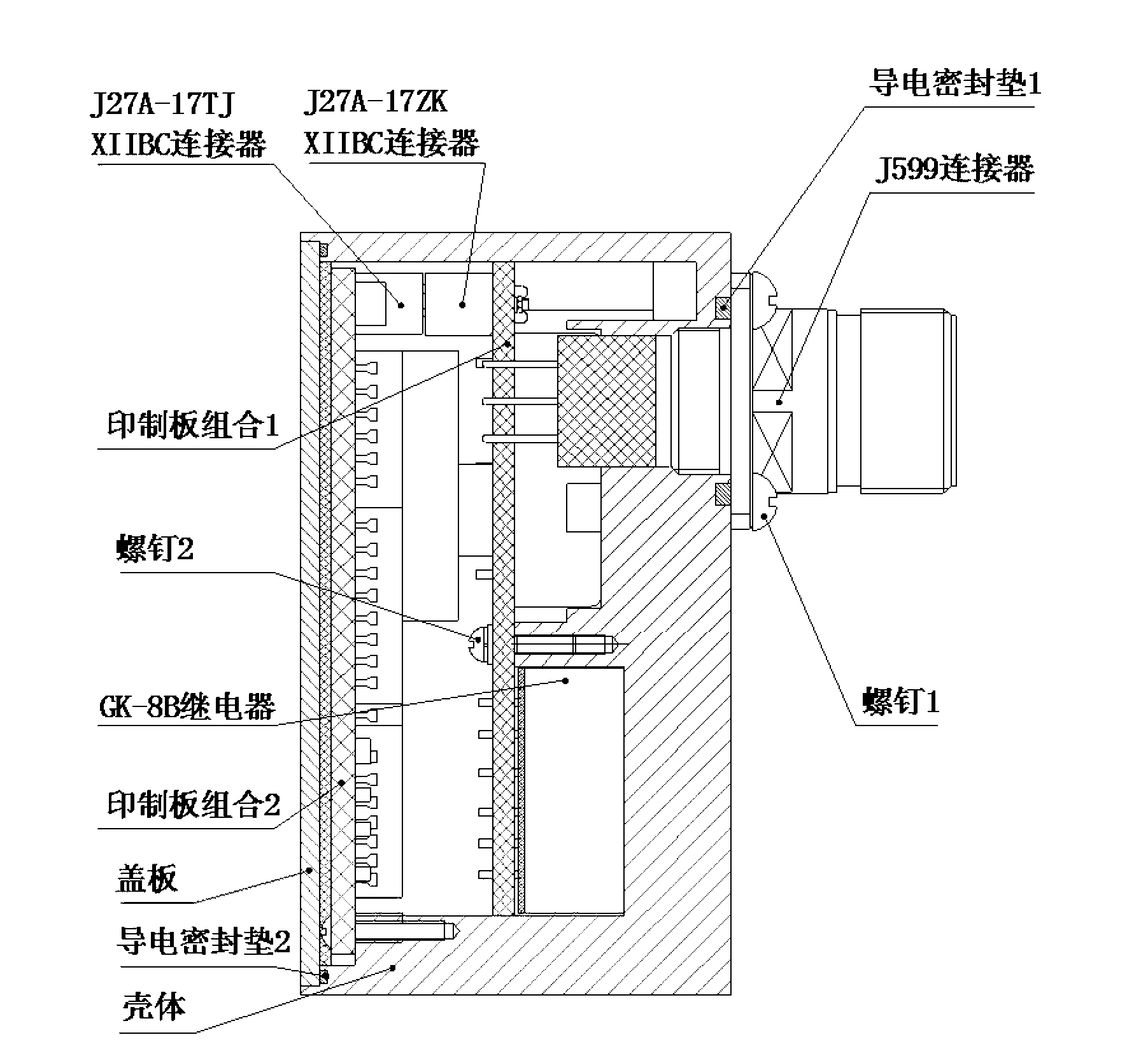

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the overload relay based on wireless connection includes J27A-17ZK connector, J27A-17TJ connector, J599 connector, first printed board assembly, second printed board assembly, GK-8B relay, cover plate, conductive Gasket, housing; first insert the J27A-17ZK connector pins into the pads of the printed board 1 and solder them, insert the J27A-17TJ connector pins into the pads of the printed board assembly 2 and perform welding. Then install the conductive gasket 1 in the groove of the housing, fix the J599 connector on the housing with screws 1, put the printed board assembly 1 into the housing, and the GK-8B relay on the printed board assembly 1 Put it inward and make reliable contact with the shell. The pins of the J599 connector are inserted into the pads of the printed board assembly 1 and soldered. On the back of the printed board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com