Fat-free ice cream and preparation method thereof

A technology of ice cream and raw materials, applied in the field of ice cream, can solve problems such as rough taste and texture, and achieve the effect of improving intestinal micro-ecological balance, fine and smooth taste, and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

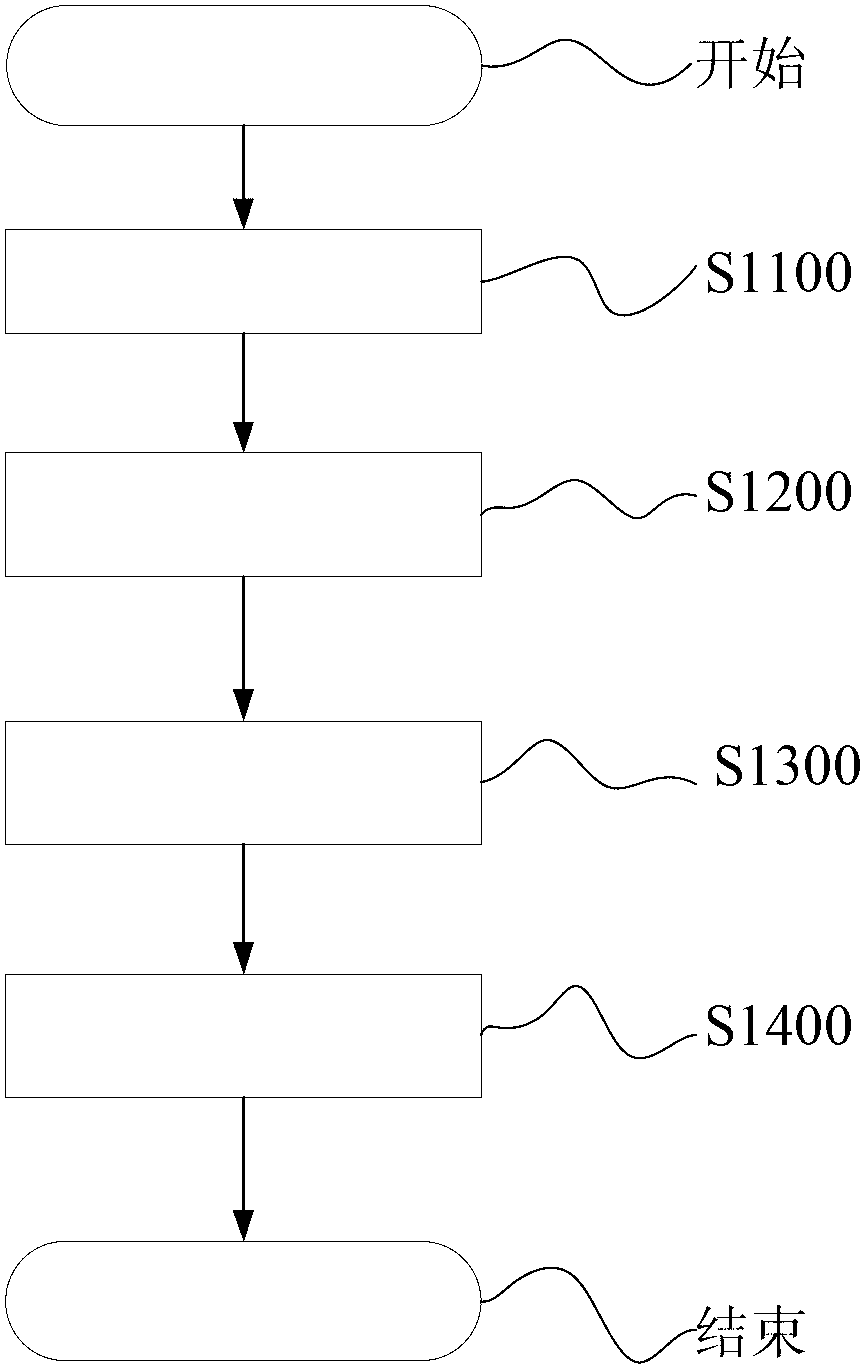

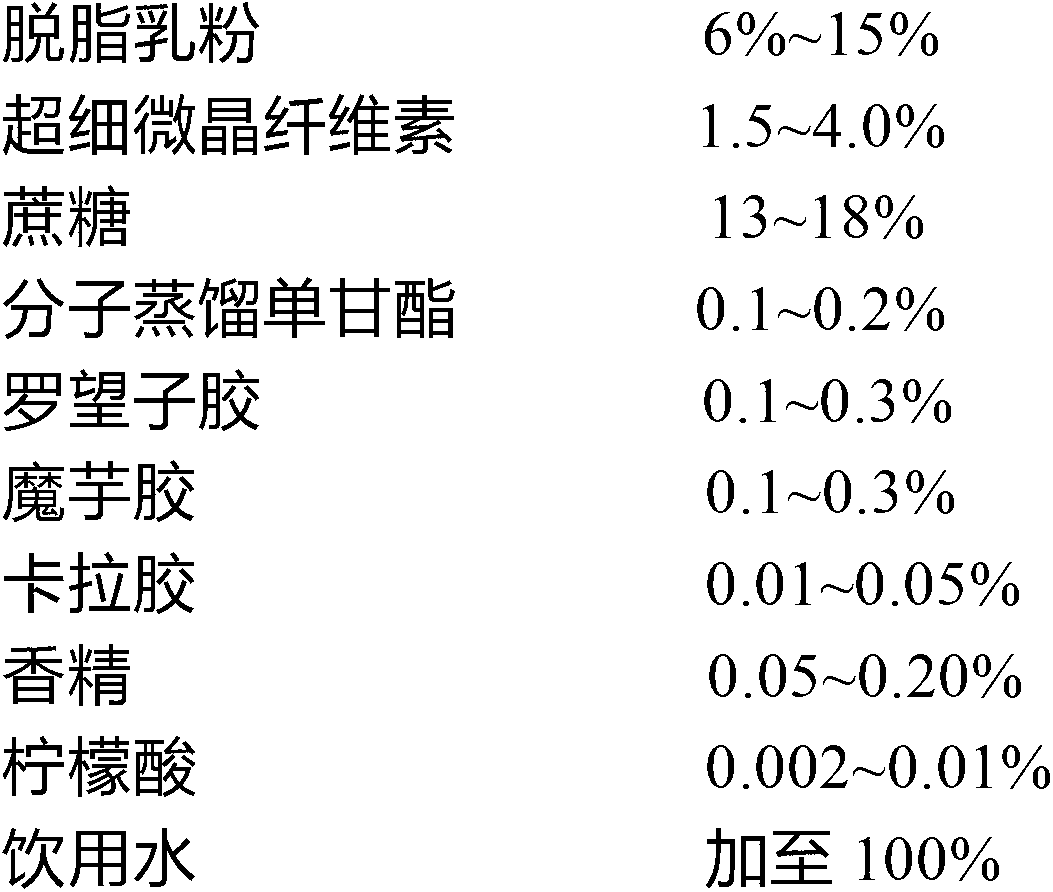

[0035] figure 1 A method for preparing ice cream according to one embodiment of the present invention is shown. According to this method, first enter the S1100 step and weigh 300 grams of skim milk powder, 75 grams of ultrafine microcrystalline cellulose, 650 grams of sucrose, 5 grams of molecularly distilled monoglycerides, 5 grams of tamarind gum, 5 grams of konjac gum and 0.5 Stir carrageenan evenly, and add 3947 grams of drinking water at 50°C to the uniformly stirred mixture until the total weight is 5000g and stir well; then enter the step S1200, sterilize the stirred emulsion at 80°C for 15 minutes, and sterilize Cool the emulsion to 60°C and homogenize at 18MPa, cool the homogeneous emulsion to 2°C and add 10ml of 1% citric acid to age for 0 hours, add 0.5ml cream essence, 0.5ml sweetener to the aged emulsion Cream essence, 0.5ml egg yolk essence, 1.0ml emulsified condensed milk essence, stir evenly for flavoring; the emulsion after flavoring enters step S1300, cools ...

example 2

[0037] figure 1 A method for preparing ice cream according to one embodiment of the present invention is shown. According to this method, at first enter S1100 step and weigh 750 grams of skim milk powder, 200 grams of superfine microcrystalline cellulose, 900 grams of sucrose, 10 grams of molecularly distilled monoglycerides, 15 grams of tamarind gum, 15 grams of konjac gum and 2.5 Stir the gram carrageenan evenly, add 3047.5 grams of drinking water at 70°C to the evenly stirred mixture to increase the total weight to 5000 g, and stir evenly; then enter the step S1200, sterilize the evenly stirred emulsion at 90°C for 5 minutes, and sterilize The final emulsion is cooled to 70°C, and homogenized at 40MPa. The homogeneous emulsion is cooled to 5°C and aged for 3 hours after adding 50ml of 1% citric acid. Add 2ml cream essence, 2ml Sweet cream essence, 2ml egg yolk essence, 1ml natural butter essence and 3ml fresh milk essence are stirred evenly for flavoring, and the flavored em...

example 3

[0039] figure 1 A method for preparing ice cream according to one embodiment of the present invention is shown. According to this method, first enter the S1100 step and weigh 500 grams of skim milk powder, 150 grams of ultrafine microcrystalline cellulose, 650 grams of sucrose, 10 grams of molecularly distilled monoglycerides, 10 grams of tamarind gum, 5 grams of konjac gum and 1.25 Stir the gram carrageenan evenly, add 3651.25 grams of drinking water at 55°C to the evenly stirred mixture, add the total weight to 5000 g and stir evenly; then enter the step S1200, sterilize the stirred emulsion at 85°C for 10 minutes, after sterilization Cool the emulsion to 65°C, homogenize at 25MPa, cool the homogeneous emulsion to 3°C, add 20ml of 1% citric acid and age for 2 hours, add 0.5ml of cream essence, 0.2 1 ml of sweet cream essence, 0.8ml of egg yolk essence, 0.4ml of natural butter essence and 0.6ml of fresh milk essence are stirred evenly for flavoring; the flavored emulsion ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com