Catalyst for preparing p-tertbutyl benzaldehyde and preparation method

A p-tert-butyl catalyst technology, applied in the field of selective oxidation of p-tert-butyl toluene to synthesize p-tert-butyl benzaldehyde as a catalyst and its preparation, can solve the problems of limited application, many reaction steps, equipment corrosion, etc., and achieve high Selectivity and activity, improved catalytic activity, less corrosive effect on equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

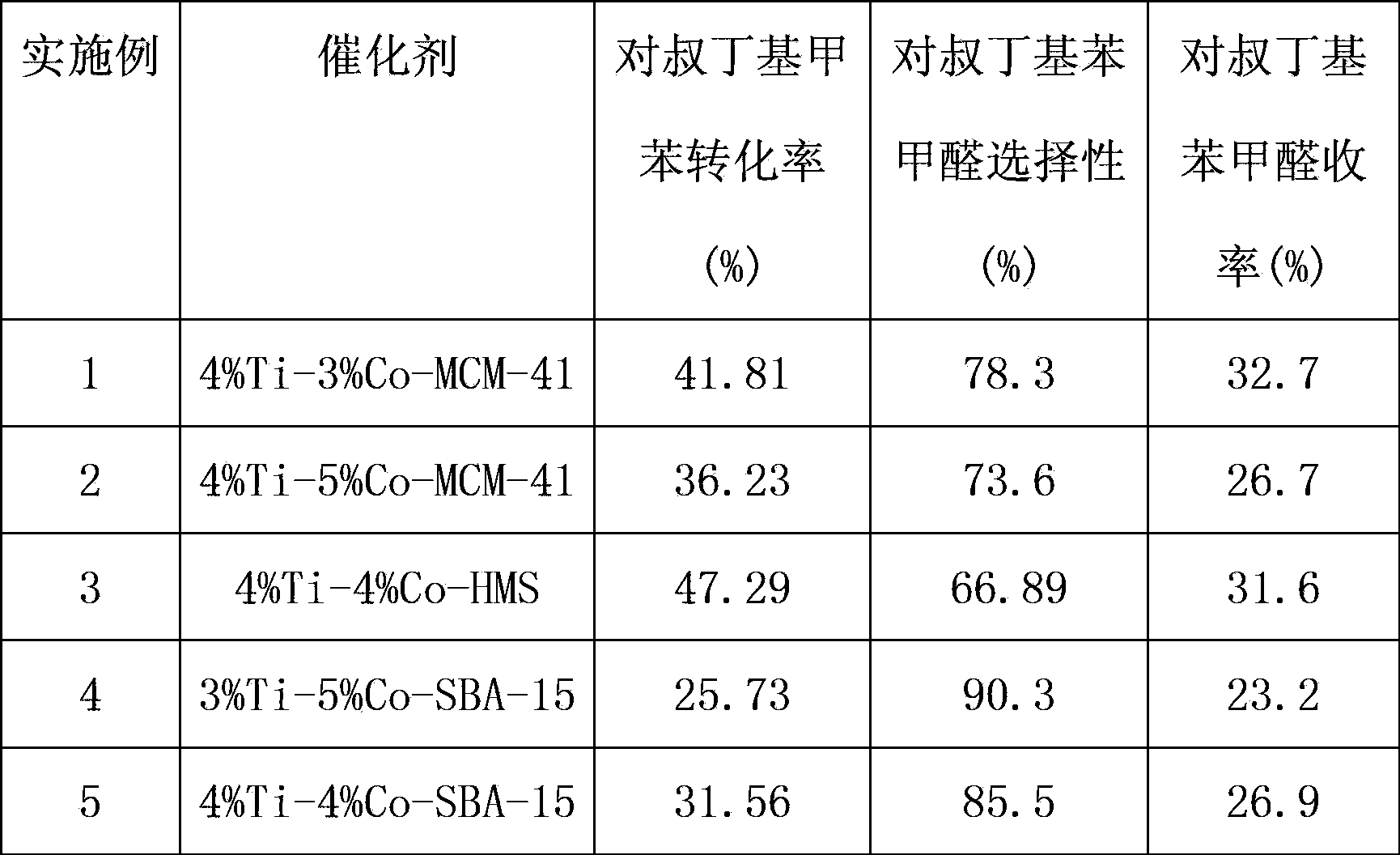

Examples

Embodiment 1

[0026] 1. Titanium dichloride (Cp2TiCl 2 ) as the titanium source, accurately weigh 1.5g of titanocene dichloride and dissolve it in 50g of chloroform (CHCl 3 ), stir well until it completely dissolves into a red transparent solution to obtain solution A; weigh 6g of MCM-41 and add it to 100g of chloroform, then drop 1.5g of triethylamine into it and stir for 8min to obtain a suspension Solution B: add solution A dropwise to suspension B, and after fully stirring, filter with a vacuum filter bottle, dry the filtered solid in the air for 6 hours, and then roast it in the air at 550°C for 3 hours to obtain 4%Ti-MCM-41 catalyst;

[0027] 2. Accurately weigh 0.85g of cobalt acetate [Co(OOCCH 3 ) 2 4H 2 0], dissolved in 40 milliliters of ethylene glycol solution, then weighed 5g of 4%Ti-MCM-41 obtained in the above preparation steps and added to Co(OOCCH 3 ) 2 4H 2 0 ethylene glycol solution, stir evenly to make it fully wet, let it stand for 24 hours, vacuumize at 200°C for...

Embodiment 2

[0029] 1. Accurately weigh 2.0g titanocene dichloride and dissolve it in 70g chloroform, stir well until it completely dissolves into a red transparent solution to obtain solution A; weigh 5.7g MCM-41 and add it to 160g chloroform, Then 1.4g of triethylamine was dropped into it and stirred for 5min to obtain suspension B. Add solution A dropwise to suspension B, stir well until the suspension turns yellow; filter and dry in the air, and then roast in air at 500°C for 4 hours to obtain 5% Ti grafted MCM-41 catalyst;

[0030] 2. Accurately weigh 1.17g of cobalt acetate, dissolve it in 30ml of ethylene glycol solution, then weigh 4g of 4%Ti-MCM-41 obtained in the above preparation steps and add it to the ethylene glycol solution of cobalt acetate, and stir evenly , make it fully wet, let stand for 30 hours, vacuumize at 200°C for 4h, and roast the dry solid at 550°C for 4h to prepare 4%Ti-5%Co-MCM-41 catalyst.

Embodiment 3

[0032] 1. Accurately weigh 2.0g of titanocene dichloride and dissolve it in 100g of chloroform, stir well until it completely dissolves into a red transparent solution to obtain solution A; weigh 8.0g of HMS and add it to 180g of chloroform, then Add 2.0 g of triethylamine dropwise, and stir for 10 minutes to obtain suspension B; add solution A to suspension B dropwise, and stir well. After suction filtration, it was dried in the air, and then calcined at 550°C for 3 hours in the air to obtain the 4% Ti grafted HMS catalyst.

[0033] 2. Accurately weigh 1.33g of cobalt acetate, dissolve it in 45ml of ethylene glycol solution, then weigh 6g of the 4% Ti grafted HMS catalyst obtained in the above preparation steps and add it to the ethylene glycol solution of cobalt acetate, and stir evenly , make it fully wet, let it stand for 24 hours, vacuumize at 230°C for 3h, and roast the dry solid at 600°C for 3h to prepare 4%Ti-4%Co-HMS catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com