Method for controlling head and tail shapes of hot-rolled strip steel

A shape control and hot-rolled strip technology, which is applied in the field of steel rolling, can solve the problems of untimely metal flow, broken strip, and deterioration of strip shape at the head and tail, so as to improve the shape quality, reduce production costs, and prevent stripping. The effect of steel head and tail plate shape deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

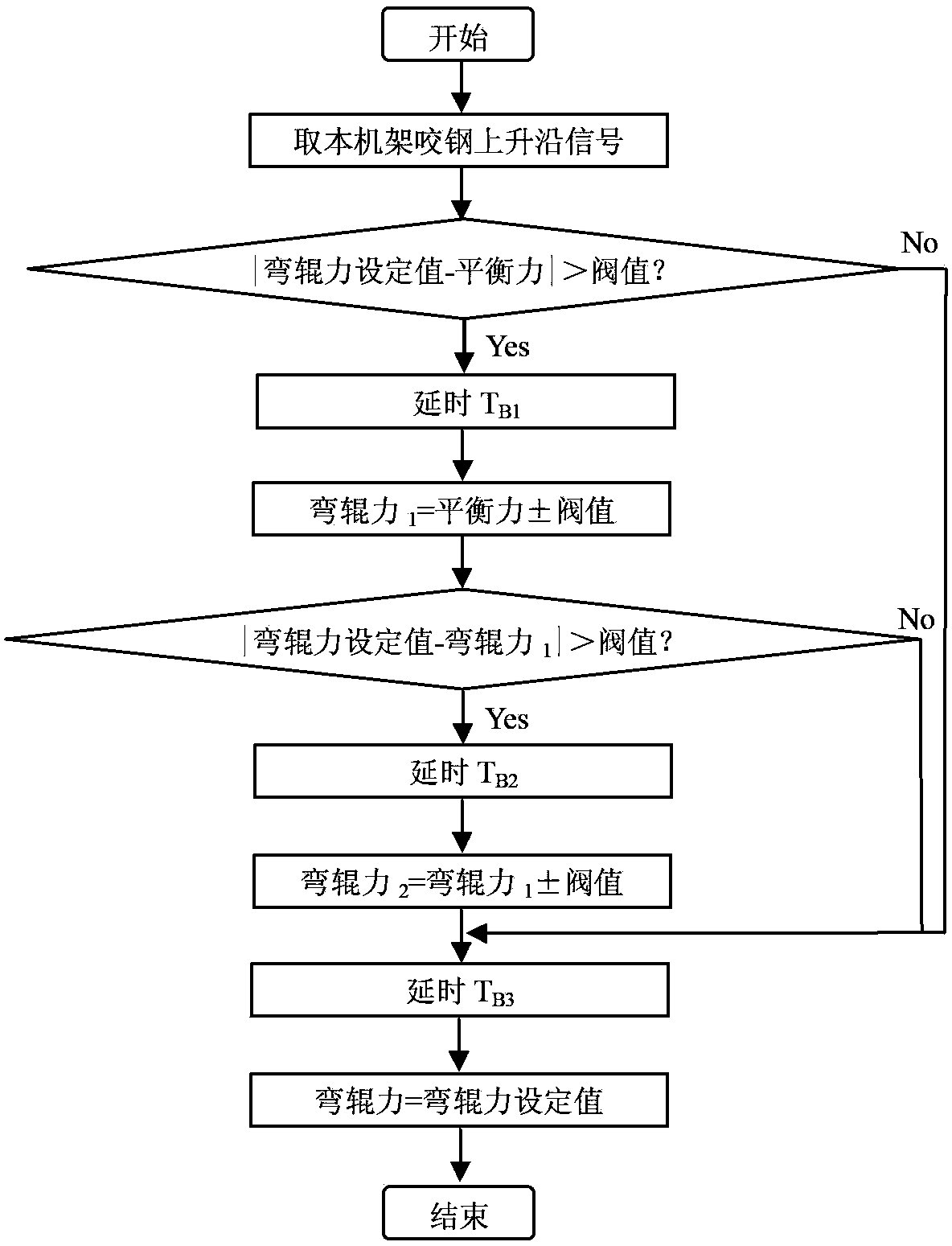

[0024] Take F 7 The balance force is 650KN, the bending force before biting the steel is equal to the balance force, the setting value of the bending force is 1200KN, and the threshold value is 250KN. Depend on figure 1 SHAPE \* MERGEFORMAT The strip head shape control flow chart shows that for the strip head shape control, the specific steps of balancing and bending roll switching are as follows:

[0025] Will F 7 Bite steel rising edge signal is introduced into F 7 The hydraulic roll bending control interface circuit of the frame is used as the control signal, when F 7 Frame hydraulic roll bending control signal received F 7 After the frame bites the steel rising edge signal, first calculate and compare whether it meets the condition of |bending force setting value - balance force | > threshold value, that is | bending force setting value 1200 KN - balance force 650 KN | > valve The value is 250 KN, the condition is established, the delay is 50ms, and the balance force...

Embodiment 2

[0027] Take F 7 The balance force of the frame is 650KN, the setting value of the bending force is 800KN, and the threshold value is 250KN. For strip head shape control, the specific steps of balance and roll bending switching are as follows:

[0028] Will F 7 Bite steel rising edge signal is introduced to F 7 The hydraulic roll bending control interface circuit of the frame is used as the control signal, when F 7 Frame hydraulic roll bending control signal received F 7After the frame bites the steel rising edge signal, first calculate and compare whether the condition of |bending force setting value-balance force|>threshold value is satisfied, that is, |bending force setting value 800 KN-balance force 650 KN |threshold value is not satisfied. After a delay of 26ms, adjust the balance force 650KN to the bending force setting value of 800KN.

Embodiment 3

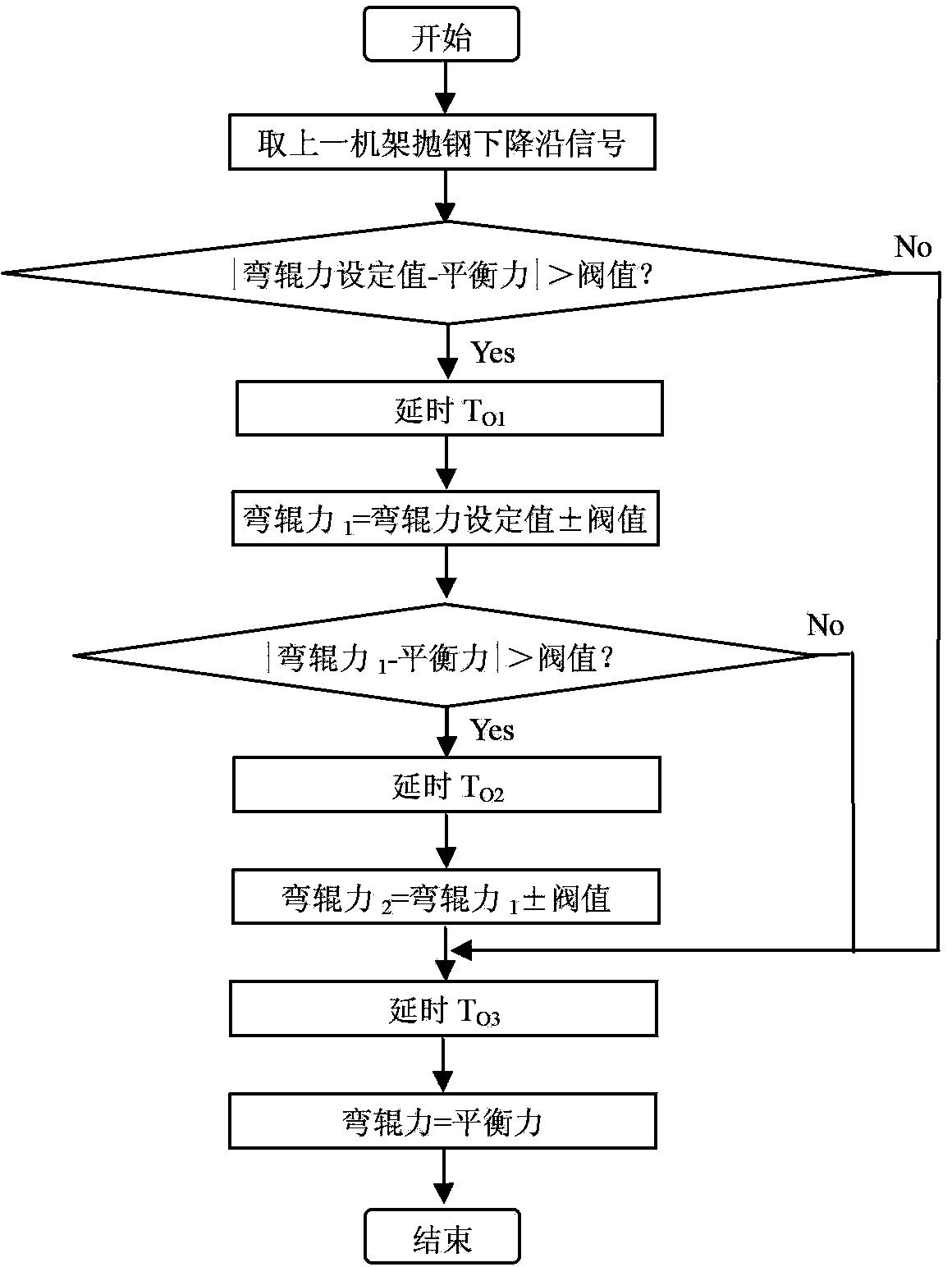

[0030] Take F 7 The balance force of the rack is 650KN, the setting value of the bending force is 1000KN, and the threshold value is 250KN. Depend on figure 2 SHAPE \* MERGEFORMAT The strip tail shape control flow chart shows that for the strip tail shape control, the specific steps of balancing and bending roll switching are as follows:

[0031] When F 7 Frame hydraulic roll bending control signal received F 6 After the frame throws the falling edge signal of steel, calculate and compare whether the condition of |bending force setting value - balance force | > threshold value is met, that is, | bending force setting value 1000 KN - balance force 650 KN | > threshold value 250 KN, the condition is established, delay 45 ms, adjust the set value of the bending force to the bending force 1 , roll bending force 1 It is equal to the set value of bending force ± threshold value. Since the set value of bending force is greater than the balance force, it is taken as a negative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com