A kind of pcd thread drilling and milling cutter

A technology for drilling and milling cutters and threads, applied in the field of PCD thread drilling and milling cutters, can solve the problems of occupying tool positions, increasing auxiliary time for tool change, and not being able to fully utilize the advantages of CNC equipment, so as to reduce tool positions and improve surface roughness , The effect of small friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

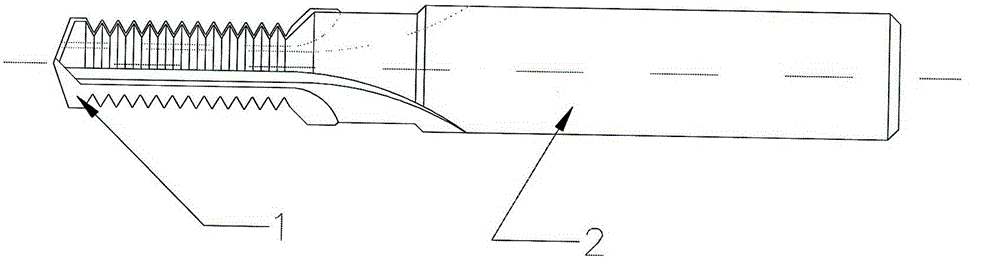

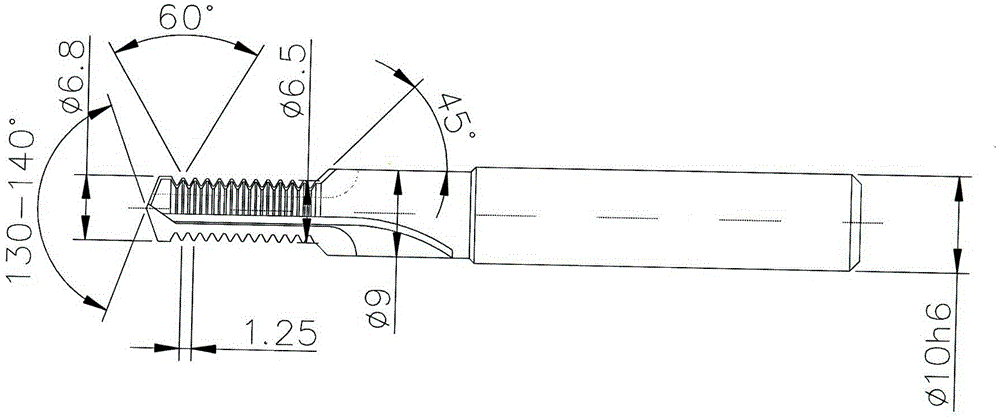

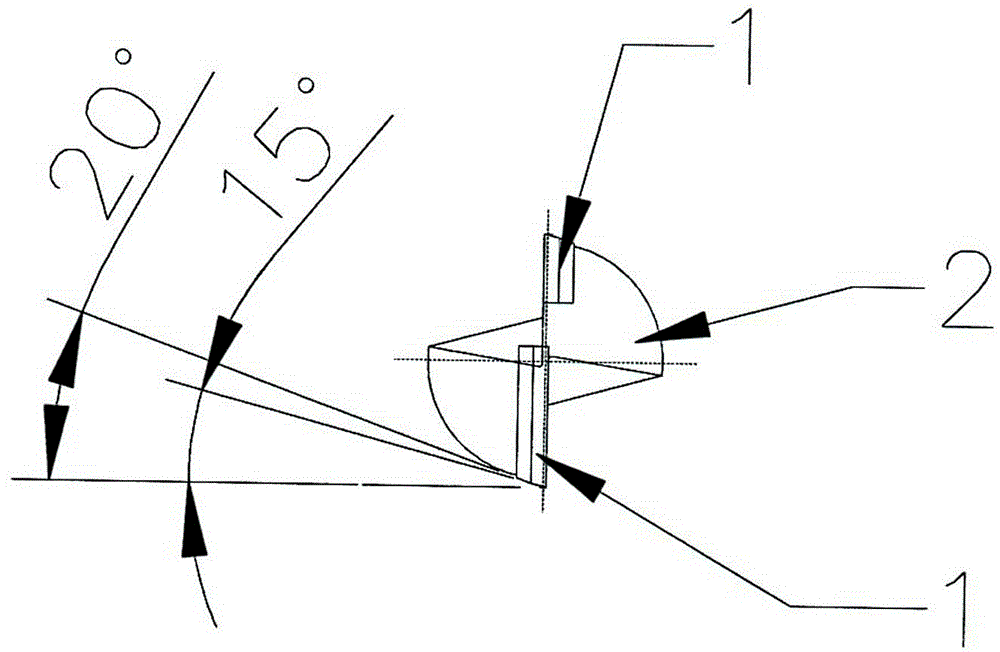

[0017] A PCD thread drilling and milling cutter of M8x1.25 is taken as an example, such as Figure 1-3 As shown, the cutter body 2 is a threaded milling cutter, the cutter body 2 is made of cemented carbide, the front end of the cutter body 2 is a drill, the drill diameter is 6.8 mm, the drill tip angle is 130 ~ 140o, the first relief angle is 12o, and the width is 0.5 mm. Two relief angles are 25o, one of which is over the center. There are two chip flutes along the 2 axis of the cutter body, the diameter of the middle thread milling cutter is 6.5 mm, the thread profile is 60o, the pitch is 1.25, the radial first relief angle is 15o, the width is 0.5 mm, and the second relief angle is 20o , The rear end of the cutter body 2 has a chamfered edge 45o, the diameter is 9 mm, and the handle is hard alloy, the diameter is mm. The cutter body blade 1 is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com